In recent years, the printing industry has evolved significantly, with DTF transfers (Direct-to-Film transfers) taking center stage as a revolutionary method for custom apparel printing. This innovative technique allows vivid designs to be printed onto a special film before being transferred onto various fabrics, providing enhanced flexibility and durability in garment decoration. As businesses seek high-quality and efficient solutions for their printing needs, the advantages of DTF printing have captured attention thanks to its ability to deliver superior results across different materials. With advancements in printing technology, DTF transfers are not just a fleeting trend but are here to redefine the standards of the industry. This article will explore the exceptional benefits and recent developments surrounding DTF transfers, shedding light on why they are transforming the landscape of custom apparel.

Also known as Direct-to-Film printing, DTF transfers represent a significant advancement in garment decoration techniques, enabling the creation of striking custom designs for various fabric types. This modern approach to custom printing focuses on efficiently transferring high-quality images onto textiles, making it an appealing option for businesses and consumers alike. By leveraging innovations in printing technology, the custom apparel industry is witnessing a shift in capabilities, where vibrant and detailed reproductions are no longer limited by traditional methods. As we delve further into the concept of DTF transfers, we will uncover its numerous advantages and the emerging trends that are shaping the future of garment printing.

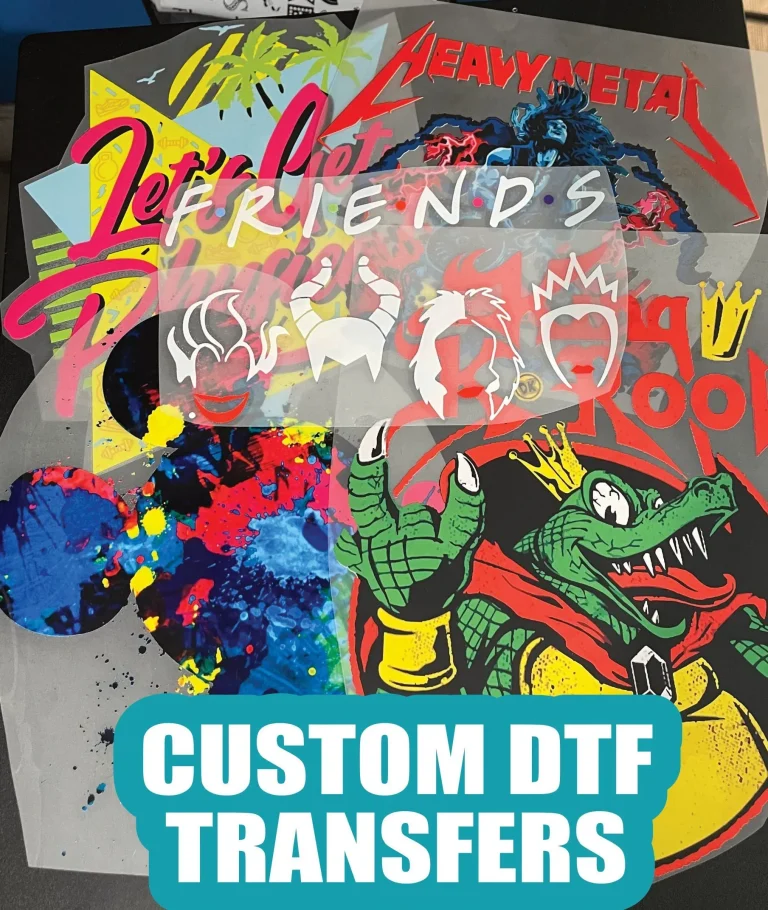

The Growing Popularity of DTF Transfers in Custom Apparel

DTF transfers have rapidly gained traction in the custom apparel industry, largely due to their remarkable versatility. This method allows for the application of complex designs with incredible detail on various fabric types, which is a significant advantage over traditional printing techniques. As more businesses seek to differentiate themselves through unique designs, the demand for high-quality printing solutions like DTF transfers continues to rise. Brands can now offer a wide range of products that appeal to diverse consumer preferences, enhancing their market presence.

Another crucial aspect contributing to the popularity of DTF transfers is the efficiency they bring to garment decoration processes. Unlike more laborious methods such as screen printing, DTF technology streamlines production, allowing for faster turnaround times. This efficiency is particularly vital in today’s fast-paced fashion market where quick adaptations to trends can make or break a brand. Consequently, many companies are integrating DTF transfers into their operational workflows to remain competitive and responsive.

The Advantages of DTF Printing Technology

One of the standout benefits of DTF printing technology is the quality of the final product. DTF transfers yield vibrant colors and intricate details that are hard to replicate with other printing methods, making them ideal for custom apparel. This level of quality helps businesses deliver impressive designs that resonate with consumers, thereby enhancing customer satisfaction and loyalty. As the expectations for design complexity continue to evolve, having the ability to produce high-quality products becomes a game-changer in the custom printing landscape.

Furthermore, DTF technology reduces waste significantly. By allowing businesses to print designs on-demand, brands can minimize the surplus of unsold inventory that often plagues traditional printing methods. This not only reduces production costs but also aligns with increasing consumer demand for sustainability in fashion. As businesses strive to adopt more eco-friendly practices, DTF transfers offer a compelling solution for combining quality with responsibility.

Key Developments in DTF Technology

Recent advancements in DTF technology are propelling it to the forefront of the printing industry. Innovations such as automatic DTF heat transfer presses are revolutionizing the way businesses approach garment decoration. These machines enhance production efficiency and ensure consistency in quality, which is paramount for scaling operations. The introduction of such technologies emphasizes the industry’s commitment to improving printing methods and establishing DTF as a leading choice for custom apparel.

Moreover, partnerships and launches from major industry players like Brother International highlight the growing recognition and support for DTF printing. Their introduction of new machinery tailored for DTF applications indicates a robust future for this technology. As more companies invest in DTF capabilities, we can expect to see an influx of creative possibilities in custom apparel design, setting new benchmarks for what can be achieved in garment decoration.

The Impact of Sam’s DTF Transfers on the Market

Sam’s DTF Transfers has become a significant player in the custom apparel printing market, illustrating the successful integration of DTF technology into service offerings. Their move to provide high-quality in-house DTF transfers showcases how businesses can leverage this printing method to cater to diverse customer needs. By prioritizing quality and flexibility, Sam’s has positioned itself as a trusted source for businesses looking to enhance their custom apparel capabilities.

In addition to their product offerings, Sam’s DTF Transfers serves as a case study in how early adoption of new technology can drive market leadership. As they continue to refine their processes and expand their reach, other companies are likely to take note and adapt their strategies accordingly. This ripple effect can lead to widespread adoption of DTF transfers, further solidifying their place in the industry.

Innovations from Snuggle and Its Role in DTF Market Growth

Snuggle’s recent launch of a dedicated DTF platform for trade printers is pivotal for the industry. By simplifying the garment decoration process, they are making it easier for resellers to meet consumer demands efficiently. This innovation not only supports the growth of DTF technology but also caters to the needs of businesses looking for intuitive solutions to streamline their operations. The platform allows for greater accessibility to high-quality printing, thereby supporting a wider range of clients in the custom apparel sector.

This strategic move by Snuggle highlights the importance of adaptability and responsiveness in the rapidly evolving garment decoration market. By developing tools that address the challenges faced by trade printers and resellers, Snuggle is enhancing the overall landscape of DTF printing. As more businesses leverage these innovative solutions, we can anticipate significant growth in the DTF market, reinforcing its position as a cornerstone of modern custom apparel printing.

Educational Initiatives Promoting DTF Printing

Events organized by industry professionals, such as the one by American Print Consultants, play an essential role in promoting awareness and education around DTF printing. These initiatives help demystify the technology and familiarize potential users with its benefits and applications. By providing insights into DTF and dye sublimation, participants gain valuable knowledge that can aid in making informed decisions about adopting these printing methods within their businesses.

Furthermore, educational events contribute to fostering a community around DTF technology, facilitating discussions among professionals eager to innovate in garment decoration. As knowledge spreads and more industry players become engaged, the overall market for DTF printing is likely to flourish, thereby encouraging continuous improvement and advancements. The emphasis on education ensures that emerging trends and best practices are shared, paving the way for a more robust future in custom apparel printing.

Frequently Asked Questions

What are DTF Transfers and how do they work in custom apparel printing?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film that is later transferred onto fabric through heat and pressure. This method is increasingly popular in custom apparel printing due to its flexibility, allowing for vibrant images on a wide variety of materials, including both natural and synthetic fabrics.

What are the benefits of using DTF printing for garment decoration?

DTF printing offers numerous benefits for garment decoration, including versatility to print on various fabrics, high-quality and vibrant image reproduction, faster order turnaround times, and reduced waste compared to traditional printing methods. These advantages make DTF technology a leading choice in the custom apparel printing industry.

How do DTF Transfers compare to traditional screen printing?

Unlike traditional screen printing, DTF Transfers provide greater flexibility and can reproduce complex images with vivid detail. Additionally, DTF printing does not require the same level of setup and can print on a wider range of fabrics, making it a preferred option for custom apparel printing.

What recent advancements have been made in DTF transfer technology?

Recent advancements in DTF transfer technology include the launch of specialized platforms like Snuggle’s for trade printers, the introduction of automatic DTF heat transfer presses, and new machinery from companies like Brother. These developments showcase the increasing adoption and innovation within the DTF printing landscape.

Can DTF technology be used for textile printing on both natural and synthetic fabrics?

Yes, DTF technology is versatile and can be effectively used on a variety of fabrics, including both natural materials like cotton and synthetic fabrics. This adaptability is one of the key advantages of DTF transfers, making them ideal for diverse custom apparel printing applications.

What factors should businesses consider when adopting DTF transfers for their printing needs?

When considering DTF transfers, businesses should evaluate factors such as printing volume, fabric types, desired quality outcomes, and technological infrastructure. Understanding these elements can help businesses leverage the benefits of DTF printing efficiently within their custom apparel printing operations.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are revolutionizing custom garment printing. |

| Understanding DTF Transfers | Involves printing designs onto special film for transfer on fabrics. Offers flexibility and vibrant image reproduction. |

| Key Developments | 1. Sam’s DTF Transfers leads in premium services. 2. Snuggle’s platform simplifies DTF processes. 3. Automatic DTF press by Ministry of Shirts enhances capabilities. 4. Brother’s new machines support DTF expansion. 5. Educational initiatives by American Print Consultants foster awareness. |

| Advantages of DTF Technology | Versatility, quality, efficiency, and reduced waste enhance its appeal. |

Summary

DTF Transfers are rapidly transforming the printing industry, revolutionizing the way custom apparel designs are created and applied. This innovative technology not only enhances the vibrancy and detail of prints but also offers the flexibility to work with a diverse range of fabrics. As highlighted by key developments from leaders in the field, such as Sam’s DTF Transfers and Brother International, DTF technology is setting new standards for efficiency and quality in garment decoration. The surge in its adoption demonstrates the pressing need for businesses to adapt to this evolving landscape, thereby positioning themselves for success in a competitive market.