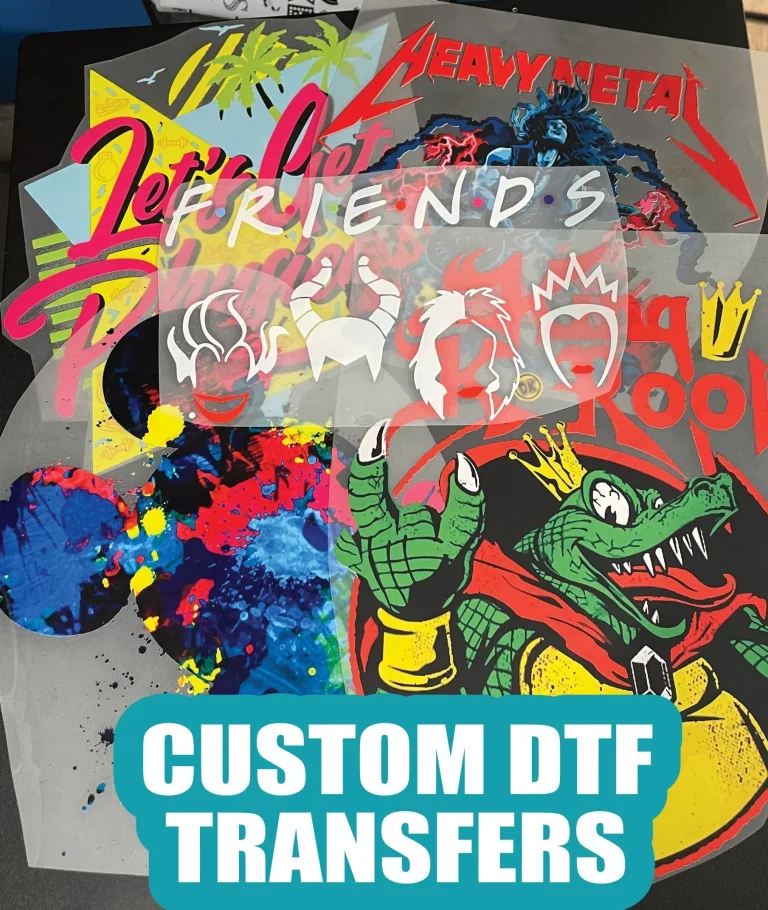

In the ever-evolving realm of custom apparel, DTF transfers have emerged as a game-changing technique that combines innovation and creativity. With the rise of Direct-to-Film (DTF) printing, designers now have access to vibrant, full-color prints that can be effortlessly applied to a variety of fabric types. This DTF printing guide aims to equip you with the essential knowledge and skills to create stunning DTF transfers that can enhance your apparel line. From understanding how to create DTF transfers to discovering the best DTF printer options, this comprehensive guide covers all the crucial aspects. Additionally, we’ll provide valuable DTF transfer tips to help you perfect your craft and impress your customers with high-quality designs.

When it comes to creating excellent visual designs for garments, the process involves various methods that are rapidly gaining popularity in the fashion industry. One of the standout techniques today is the use of film-based transfers, which allows for high-resolution graphics to be effectively applied to textiles. This method is not only user-friendly but also versatile, making it a favorite among designers and hobbyists alike. In exploring this topic further, we will delve into details regarding film transfer techniques, suitable printing machines, and insightful tips for achieving exceptional results in your printed fabric projects.

Understanding the Basics of DTF Transfers

Direct-to-Film (DTF) transfers have quickly gained popularity in the custom apparel world. This innovative method allows you to print high-quality designs onto a special film that can be transferred onto various fabrics with ease. The DTF process starts by creating your artwork, which is then printed onto a PET film. This film is crucial for achieving vibrant colors and intricate details that can withstand wear and tear. It’s essential to familiarize yourself with how to create DTF transfers effectively, as mastering these basics will set you up for success in custom printing.

As you delve into DTF printing, you’ll find that it offers immense versatility, allowing for application on materials ranging from cotton to polyester. Understanding the dynamics of ink adhesion, heat settings, and transfer times is important to ensure your designs are not only visually appealing but also durable. Recognizing these fundamentals can significantly enhance your DTF projects, equipping you with the skills to produce high-quality prints for both personal and commercial use.

Frequently Asked Questions

How to create DTF transfers effectively?

Creating DTF transfers effectively starts with designing high-resolution artwork and using a compatible DTF printer. Follow a step-by-step process: first, print your design on DTF film, apply adhesive powder while the ink is wet, cure the powder, and finally use a heat press to transfer the image onto your desired fabric.

What are the essential materials needed for DTF printing?

The essential materials for DTF printing include a DTF printer (like Epson L1800), DTF inks, DTF film, adhesive powder, a heat press machine, and design software such as Adobe Illustrator or Photoshop. Each of these components plays a crucial role in creating high-quality DTF transfers.

What is the best DTF printer for beginners?

The best DTF printer for beginners is the Epson L1800 or the XP600, as they offer high-quality printing capabilities and are user-friendly. These models are ideal for those just starting in the world of DTF printing, ensuring excellent results.

Can you provide DTF transfer tips for beginners?

Certainly! For beginners, here are some DTF transfer tips: always use high-resolution images for your designs, ensure your adhesive powder is applied evenly, pre-press your fabric to eliminate moisture, and calibrate your heat press for different fabric types to achieve the best results.

What are common mistakes when creating DTF transfers?

Some common mistakes in creating DTF transfers include using low-resolution images, not properly applying adhesive powder, incorrect heat press settings, and neglecting fabric pre-pressing. Avoiding these pitfalls will ensure better quality and durability of your DTF transfers.

How do I enhance my DTF transfer designs?

Enhancing your DTF transfer designs can be achieved by focusing on vibrant colors and high contrast, utilizing layering techniques in design software, and staying aware of current trends in custom apparel. Adding unique elements that resonate with your target audience will make your DTF transfers stand out.

| Key Aspects | Details |

|---|---|

| What is DTF Printing? | DTF printing is a method that prints high-resolution designs on PET film and transfers them to garments using heat and adhesive powder. |

| Necessary Supplies | 1. DTF Printer (Epson L1800, XP600) 2. DTF Inks (pigment-based) 3. DTF Film (cold or hot peel) 4. Hot-melt Adhesive Powder 5. Heat Press Machine 6. Design Software (Adobe Illustrator, Photoshop) |

| Step-by-Step Process | 1. Design your artwork (high-res, .PNG/.PSD formats) 2. Print the design on DTF film 3. Apply adhesive powder and cure the film 4. Pre-press fabric, set heat press, and transfer design |

| Key Tips for Success | 1. Customize products to enhance brand recognition. 2. Maintain quality control of printing equipment. 3. Focus on eco-friendly practices for sustainability. |

| Current Trends | 1. Sustainability in production with eco-friendliness. 2. Increasing personalization in apparel design reflecting cultural stories. |

Summary

DTF transfers are an innovative means of enhancing custom apparel production, allowing creators to achieve vibrant prints that seamlessly adhere to different fabrics. This method not only stands out for its versatility but also emphasizes the importance of quality materials and techniques. As DTF technology evolves, understanding its intricacies will empower creators to produce unique, high-quality designs while prioritizing sustainability in their practices. Therefore, mastering DTF transfers will position you at the forefront of the custom printing field.