In the rapidly evolving world of print technology, **UV DTF transfers** are making a remarkable impact, redefining how we think about custom transfer solutions. This innovative method employs ultraviolet light to cure ink directly onto film, resulting in vibrant, durable prints suitable for various materials like fabrics, metals, and plastics. As industries seek efficient solutions, UV DTF technology stands out for its unmatched versatility and potential for high-quality output, making it a favorite among artists and businesses alike. The recent advancements in DTF printing have opened doors to new creative possibilities, and this blog post aims to explore why UV DTF transfers are at the forefront of printing innovations. From lower production costs to the ability to print on multiple substrates, the benefits are compelling and deserving of attention.

When we discuss **UV DTF transfers**, we are exploring a groundbreaking form of printing that utilizes ultraviolet technology to cure ink on films. This approach, often referred to in broader terms as direct-to-film printing, offers a unique and efficient way for businesses to create custom graphics and designs. With its ability to deliver complex images and vibrant colors, this printing method is rapidly gaining traction in diverse sectors, from commercial printing to artistic endeavors. The versatility of this technology makes it ideal for a range of applications, allowing creators to produce high-quality items across various materials. As a result, UV printing techniques are becoming essential tools in modern production landscapes, pushing the boundaries of what is possible in the realm of customization.

What are UV DTF Transfers?

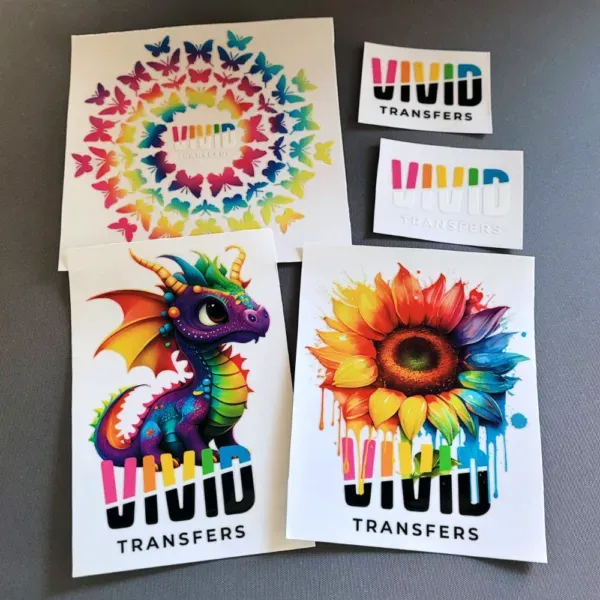

UV Direct-to-Film (DTF) transfers represent a cutting-edge method in print technology that uniquely combines the principles of UV printing with the adaptability of transfer applications. This technique utilizes ultraviolet light to cure inks as they are deposited on a specially coated film, creating vivid and long-lasting prints. Unlike traditional screen printing and digital methods, UV DTF allows for intricate details, smooth gradients, and a wider color gamut, making it a favored choice among designers seeking high-quality output.

The application range of UV DTF transfers is vast, allowing printers to work not just on textiles but also on materials such as metal, wood, glass, and plastics. This versatility opens new creative avenues for artists and entrepreneurs, enabling them to produce customized items that cater to specific market demands. The fast curing process involved in UV DTF printing also leads to reduced production times, marking a significant shift in how print jobs are approached in contemporary settings.

Frequently Asked Questions

What are UV DTF transfers and how do they work in modern print technology?

UV DTF (Direct-to-Film) transfers utilize ultraviolet light to cure ink onto films, producing vibrant and durable prints suitable for various substrates. This innovative printing technology allows for high-quality images to be printed with intricate details, enhancing the overall print quality.

What advantages do UV DTF transfers offer over traditional printing methods?

UV DTF transfers provide several advantages, including lower production costs, versatility across multiple materials, and high-quality outputs that resist fading and scratching. This makes them ideal for both small and large-scale production needs in the current print market.

How do custom transfer solutions enhance the functionality of UV DTF printing?

Custom transfer solutions in UV DTF printing empower artists and small businesses by offering tailored options that cater to unique needs. These innovations ensure high-quality prints with vibrant colors, allowing for enhanced creativity and personalization in printed products.

What are some recent technological advancements in UV DTF printing?

Recent advancements in UV DTF printing include the introduction of new UV DTF printers at trade shows like FESPA, innovations in roll-to-roll technology, and the launch of compact printers combining DTF capabilities with lamination, improving production efficiency and versatility.

In what way does UV DTF printing contribute to sustainability in the print industry?

UV DTF printing promotes sustainability by reducing waste through efficient production processes, which minimize the need for additional materials. This aspect of UV DTF technology aligns with the industry’s growing focus on eco-friendly solutions.

Who can benefit from using UV DTF transfer technology?

Artists, crafters, and commercial businesses alike can benefit from UV DTF transfer technology. It offers them a versatile and cost-effective means to produce high-quality, customized products that meet diverse market demands.

| Key Points | Details |

|---|---|

| Introduction | UV DTF transfers revolutionize the print industry by providing an efficient, cost-effective alternative to traditional methods. |

| Understanding UV DTF Transfers | Utilizes UV light to cure ink onto films for vibrant, durable prints on diverse materials. |

| Key Developments | Emergence of custom solutions, notable product launches, and technological innovations enhance efficiency and versatility. |

| Benefits | Lower costs, versatility in printing materials, high-quality outputs, and suitability for various surfaces. |

| Impact on Industry | Transforming creative sectors, commercial printing, and supporting sustainability efforts through efficiency improvements. |

Summary

UV DTF Transfers are the forefront of modern printing technology, drastically transforming the landscape of print production. As this innovative method utilizes UV light to seamlessly cure inks onto various materials, it delivers exceptional quality and durability, catering to a wide array of applications. Businesses and creative professionals can benefit immensely from the reduced production costs and the ability to print on multiple substrates, expanding their creative possibilities. With continuous advancements leading to more efficient and adaptable solutions, UV DTF Transfers are poised to redefine the standards of excellence in the print industry, ushering in an era where creativity and functionality coexist seamlessly.