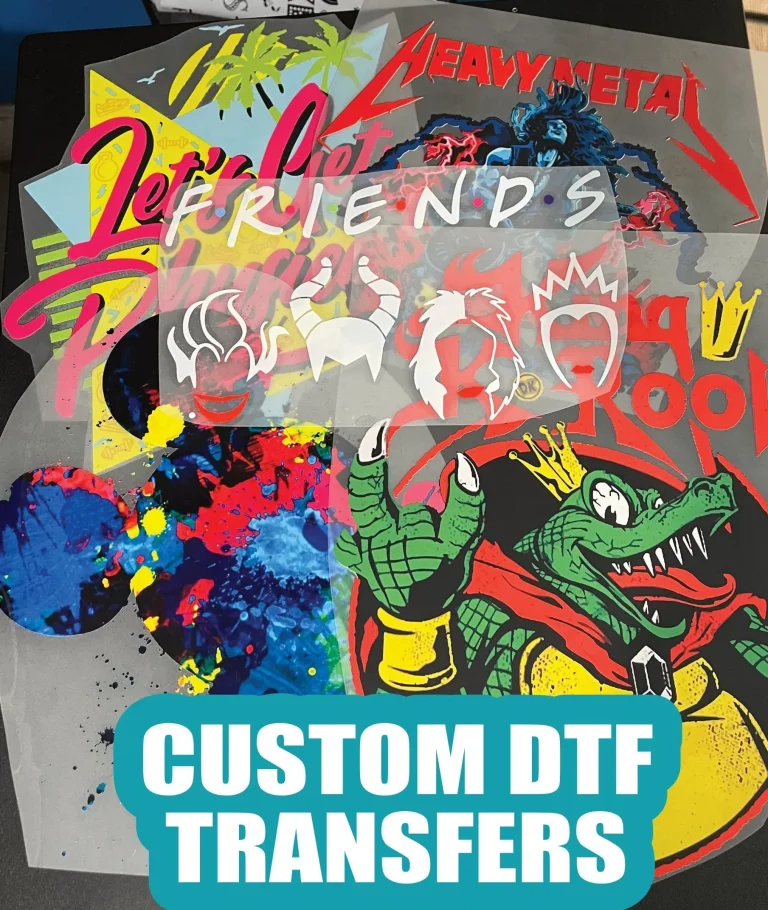

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel by offering a superior method for transferring intricate designs onto fabric. This cutting-edge printing technique allows designers to create vivid, eye-catching imagery while retaining exceptional detail and clarity. As the marketplace becomes increasingly competitive, understanding the impact of DTF printing on apparel design is essential for brand differentiation. With advantages such as optimal size tailoring and effective color management, DTF transfers set the stage for stunning visual experiences. In this article, we will explore how to leverage these benefits to maximize your design impact and enhance your product offerings.

Also known as Direct-to-Film printing, this innovative methodology presents a game-changing approach to transferring designs onto textiles. Recognized for its ability to deliver high-quality graphics, this printing technique caters to the demands of modern apparel design. By focusing on critical aspects like size optimization and meticulous color management, creators can craft stunning visuals that resonate with consumers. The evolution of this technology continues to reshape the landscape of garment decoration, making it essential for designers to adapt their strategies. Join us as we delve deeper into the world of DTF and uncover its potential for transforming your apparel business.

The Evolution of Direct-to-Film Transfers

Direct-to-Film (DTF) transfers have transformed the landscape of custom apparel printing. Initially introduced as a complement to existing methods like screen printing, DTF technology has gained traction for its efficiency and versatility. Unlike traditional methods that often rely on more complex setups, DTF allows for quicker turnarounds and the ability to produce intricate, multi-colored designs without extensive screen setups.

Not only does the DTF process enable a wider range of color applications, but it also showcases the potential for details and gradients that are often challenging with other techniques. As more designers explore DTF for their projects, its role in streamlining production and expanding creative possibilities becomes clearer.

Frequently Asked Questions

What are DTF transfers and how do they work in apparel design?

DTF transfers, or Direct-to-Film transfers, involve printing intricate designs on a specialized film that is then applied to garments using heat and pressure. This method allows for vibrant colors and detailed graphics, making it ideal for custom apparel design.

How important is size optimization when creating DTF transfers for clothing?

Size optimization is crucial for DTF transfers, as the design must complement the dimensions of the garment. Larger graphics may suit hoodies, while smaller designs work better on t-shirts. Tailoring the size ensures a balanced and appealing look.

What role does color management play in the quality of DTF transfers?

Color management is vital in DTF transfers, as it influences how colors appear on fabric. Using high-resolution images and correct color profiles in design software ensures that the final product displays the intended vibrancy and accuracy.

What software tools are recommended for creating DTF transfer designs?

Popular software for DTF transfer design includes Adobe Illustrator and Photoshop for advanced users, while Inkscape and CorelDRAW offer cost-effective alternatives. Beginners might prefer Canva for its user-friendly, drag-and-drop features.

What are the best practices for preparing artwork for DTF transfers to ensure quality results?

To prepare artwork for DTF transfers effectively, use designs with transparency to blend with the fabric, and maintain consistent temperature and pressure during application. This ensures proper adhesion and preserves the design quality.

What emerging trends are influencing DTF transfers in the custom apparel industry?

Emerging trends in DTF transfers include innovative printing equipment that expands color options and a focus on sustainability with eco-friendly inks. These trends enhance design capabilities while addressing environmental concerns.

| Key Point | Details |

|---|---|

| DTF Transfers Overview | A revolutionary technique for applying intricate designs to fabric, utilizing special coated films. |

| Importance of Size | Design size should match garment type for effective display, ensuring balance and appeal. |

| Color Management | High-resolution images (300 DPI) and correct color profiles ensure vibrant printed colors. |

| Software Tools | Use tools like Adobe Illustrator, Inkscape, or Canva to create designs suitable for DTF transfers. |

| Artwork Preparation | Designs should consider transparency and maintain consistency in application process. |

| Quality Checks | Check color accuracy, size appropriateness, and detail clarity before production. |

| Emerging Trends | New printers and sustainable practices are enhancing DTF transfer capabilities. |

Summary

DTF transfers are a transformative method for custom apparel design that emphasizes vibrant colors and intricate patterns. Understanding the nuances of size, color management, and artwork preparation is crucial in maximizing the effectiveness of your designs. By utilizing the appropriate software tools and maintaining rigorous quality checks, you can ensure that your DTF transfers not only meet but exceed your expectations. As technology evolves, keeping abreast of new trends in DTF transfers will enable you to innovate your designs, ultimately enhancing your offerings in the competitive landscape of custom fashion. Whether you’re a novice or a seasoned designer, embracing these techniques can significantly improve your design outcomes.