DTF Transfers, or Direct to Film Transfers, have emerged as a revolutionary method in the realm of custom apparel printing, capturing the attention of many entrepreneurs and creatives alike. This innovative process involves printing vibrant designs directly onto a specialized film, which can then be applied to various fabric surfaces. To achieve the best results with DTF transfers, it’s crucial to equip yourself with essential tools for DTF success, including high-quality DTF printers, suitable DTF transfer film, and reliable DTF adhesive powder. These DTF printing tools not only streamline the printing process but also ensure that your designs remain bold and durable over time. In this article, we will delve into the five must-have tools that will elevate your DTF printing endeavors and keep your creative business ahead of the competition.

Direct to Film printing is quickly transforming the landscape of customized garment production and is often referred to as DTF imaging. This technique allows for seamless printing of intricate designs onto special films, making it easier than ever to transfer these prints onto textiles. Central to achieving success in this process are vital printing supplies, including premium DTF printers, coated transfer film, and effective adhesive powders. As we explore the best practices and the necessary components for thriving in DTF applications, this article aims to equip you with the knowledge required to leverage these advanced tools effectively. With the right resources and techniques, your creative visions can move from concept to reality, ensuring a lasting impact in the custom apparel market.

Understanding DTF Transfers: A Game Changer for Apparel Printing

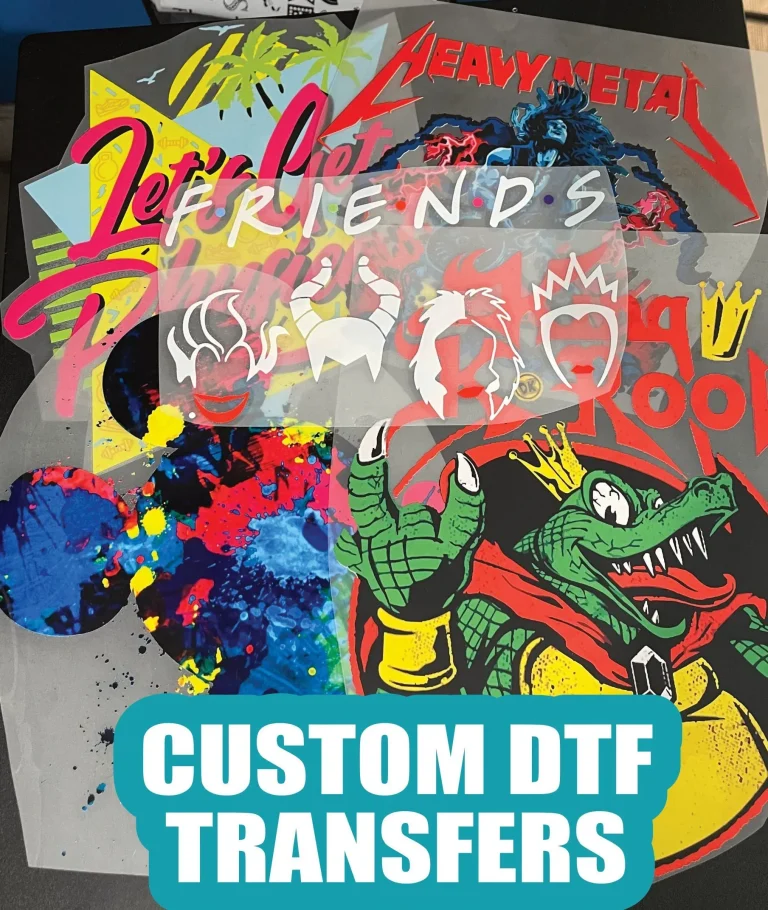

Direct to Film (DTF) transfers have revolutionized the custom apparel printing industry by offering a unique combination of quality and versatility. Unlike traditional methods, DTF printing allows for intricate designs and vibrant colors that can be applied to various fabrics, from cotton to polyester. This cutting-edge technology eliminates the limitations of screen printing and gives designers the freedom to unleash their creativity without compromise.

By using specialized DTF printers, businesses can achieve a level of detail and color saturation that was previously unattainable. The DTF process not only enhances the visual appeal of garments but also ensures the prints are durable and resistant to wear and washing. As this method gains traction, understanding how to implement DTF transfers effectively is essential for any serious apparel printer.

The Importance of Quality DTF Printing Tools

To harness the full potential of DTF printing, having the right tools is paramount. Key components such as DTF printers, transfer films, adhesive powders, and curing equipment play a significant role in determining the final product’s quality. High-quality DTF printers are designed to produce striking graphics and maintain consistency across multiple prints, making them the backbone of any successful DTF operation.

Additionally, using the best DTF transfer film ensures that colors appear vibrant and true to the original designs. Coupled with quality adhesive powders, which bond the print securely to the fabric, these tools set the stage for producing garments that not only look great but also stand the test of time. Investing in these essential DTF printing tools is a critical step toward ensuring the success of your custom apparel venture.

Choosing the Best DTF Printers for Your Needs

When it comes to choosing the best DTF printers, several factors must be taken into consideration. Not only should you look at the print resolution and color capabilities, but also the printer’s compatibility with DTF transfer films and adhesive powders. The ideal DTF printer should be user-friendly and equipped with advanced features that enhance workflow efficiency, allowing for smoother operation and faster turnaround times.

Brands that stand out in the DTF printer market often utilize cutting-edge technology, such as improved ink systems and precise temperature controls, to deliver superior quality prints. By selecting a reputable printer that aligns with your production volume and specific needs, you will set your business up for continued success in producing detailed and durable DTF transfers.

Maximizing Results with DTF Adhesive Powders

DTF adhesive powders play a crucial role in the transfer process, ensuring that the printed designs adhere properly to garments and maintain integrity over time. The choice of adhesive powder can significantly affect the final outcome, with variations in composition affecting the strength of the bond between the fabric and print. Opting for high-quality adhesive powders ensures that the prints resist fading and damage from washing, ultimately extending the life of your designs.

Moreover, understanding the proper application and curing techniques for DTF adhesive powders is essential for achieving optimal results. Factors such as the amount of powder applied, curing time, and temperature all contribute to the strength of the bond. By following best practices in using DTF adhesive powders, you can produce high-performing transfers that satisfy customers and enhance your brand’s reputation.

The Role of DTF Transfer Films in Print Quality

The type of DTF transfer film you choose can greatly impact the overall quality of the print. These films are specifically designed to allow vibrant inks to adhere properly and transfer seamlessly onto a variety of surfaces. Selecting high-quality DTF transfer films compatible with your specific printer model ensures that you get the best color retention and durability from your prints.

Additionally, advancements in DTF transfer film technology continue to emerge, making it easier to achieve the desired finish and texture in your prints. Understanding the differences between matte and glossy finishes can also help you cater to different customer preferences and market trends. Utilizing superior DTF transfer films is integral to elevating your printing capabilities and enhancing customer satisfaction.

Embracing Technological Advancements in DTF Printing

As the DTF printing landscape evolves, staying abreast of emerging technological advancements is vital for staying competitive. Innovations such as nine-color printing systems are expanding the artistic possibilities for designers, allowing for richer color combinations and more complex designs. These technological improvements not only enhance the quality of prints but also enable businesses to offer a wider array of products, appealing to diverse consumer tastes.

Automation is proving to be another game-changer in the DTF printing industry. Automated processes for cutting and curing are enhancing efficiency and reducing labor costs, making large production runs more feasible without sacrificing quality. By embracing these tech advancements, apparel brands can streamline their operations, reduce waste, and respond more effectively to market demands.

Frequently Asked Questions

What are the essential tools for DTF Transfers?

To achieve successful DTF transfers, you need five essential tools: a high-quality DTF printer, adhesive powders, DTF transfer film, curing equipment (like heat presses or ovens), and robust design software. These tools work together to ensure vibrant and durable prints on fabric.

How does DTF transfer film impact print quality?

The quality of DTF transfer film is vital as it is specifically coated to allow vibrant inks to adhere and transfer seamlessly. Using high-quality film that is compatible with your DTF printer ensures superior print quality, helping your designs to look their best.

What is the role of adhesive powder in DTF Transfers?

Adhesive powder is crucial in DTF transfers as it bonds the ink from the DTF film to the garment. After printing, the film is coated with the adhesive powder, which, when cured correctly, ensures a strong and durable attachment that withstands washing and wear.

What should I look for when selecting the best DTF printers?

When selecting the best DTF printers, consider the printer’s capability to produce high-quality graphics, its speed, and compatibility with various DTF transfer films. Advanced technology, such as nine-color systems, can enhance color reproduction, providing more vibrant and intricate designs.

How does curing equipment affect DTF Transfers?

Curing equipment, such as heat presses or ovens, is essential for DTF transfers as it ensures the adhesive powder melts and bonds the design to the fabric. Proper temperature and timing during the curing process are crucial for achieving high-quality, long-lasting prints.

Can I use any design software for DTF printing?

While you can use various design software for DTF printing, it’s best to choose robust programs that can handle high-resolution graphics. Software like Adobe Illustrator or specialized DTF design software is recommended, as it allows for optimal design adjustments and color management for printing.

| Tool | Description |

|---|---|

| DTF Printers | Specialized printers for high-quality graphics directly onto DTF film, essential for vivid details and colors. |

| Adhesive Powders | Coated onto printed film to bond designs to fabric; critical for durability and wash resistance. |

| DTF Transfer Film | Film coated for optimal ink adhesion, affecting print quality; high compatibility with printers is necessary. |

| Curing Equipment | Heat presses or ovens used to cure adhesion; correct temperature and timing is crucial for success. |

| Design Software | Robust software for creating high-resolution designs; essential for optimizing layout and colors before printing. |

Summary

DTF Transfers are revolutionizing custom apparel printing, offering exceptional quality and customization options. To achieve the best results in DTF printing, it is crucial to invest in five essential tools: specialized DTF printers that deliver vibrant graphics, high-quality adhesive powders for a durable bond, appropriate DTF transfer films for excellent ink adhesion, reliable curing equipment for effective processing, and robust design software for creating compelling designs. Embracing these tools not only supports high-quality outcomes but also enables businesses to adapt to emerging trends and technological advancements in the industry. As the custom apparel market continues to evolve, staying equipped with the right resources will ensure ongoing success and innovation in DTF Transfers.