DTF transfers, or Direct-to-Film transfers, are rapidly transforming the print industry, revolutionizing the way custom apparel is created and adorned. This innovative technique allows for high-quality prints on a variety of garments, from T-shirts to hoodies, making it an attractive option for businesses aiming to deliver personalized products. As the demand for unique and custom designs grows, DTF printing stands at the forefront, combining efficiency and vibrancy to meet the needs of today’s market. Moreover, this sustainable printing solution reduces waste and reliance on harmful chemicals, aligning with increasing environmental consciousness in the manufacturing sector. As we delve deeper into the impact of DTF transfers, we’ll explore how this technology is setting new standards in garment decoration and pushing the boundaries of the print industry.

Direct-to-Film printing is reshaping the landscape for those involved in fabric customization and decoration. Known for its precision and the ability to produce vibrant prints, this advanced method is becoming a preferred choice among businesses seeking efficiency and quality in their production processes. By enabling quick turnaround times and excellent durability of designs, the DTF printing approach caters not only to the rising demand for personalized apparel but also emphasizes environmental responsibility. As player companies push to innovate within the realm of garment decoration, this technology emerges as a key player in the evolution of sustainable printing practices. Let’s take a closer look at how this approach is revolutionizing the print industry, paving the way for future advancements.

The Future of DTF Transfers in Custom Apparel

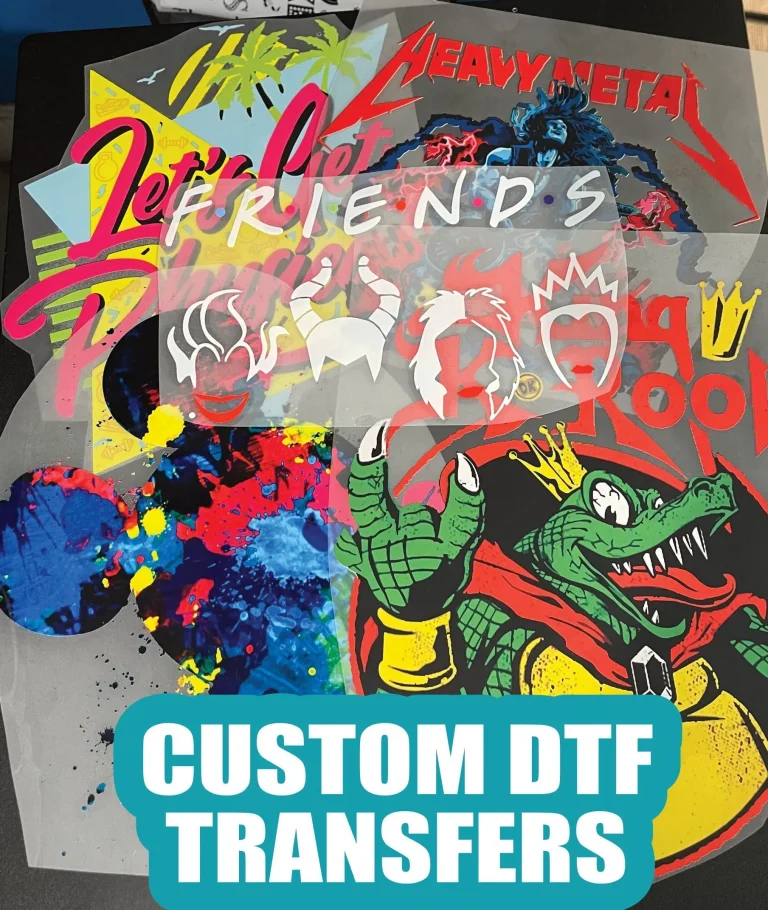

DTF transfers have quickly become synonymous with innovation in custom apparel, acting as a catalyst for the evolution of garment decoration. As the appetite for personalized fashion choices continues to grow, businesses are turning to DTF technology to meet the demand for unique designs. This method allows for an array of artwork styles—ranging from intricate graphics to bold patterns—making it ideal for brands looking to stand out in the increasingly competitive market. Furthermore, DTF printing accommodates various fabric types, expanding the possibilities for custom apparel beyond traditional textiles.

One of the primary advantages of DTF transfers is their ability to produce high-quality prints that retain their vibrancy even after multiple washes. This durability not only satisfies consumer expectations but also positions brands as reliable players in the print industry. Companies can now fulfill bulk orders with personalized options efficiently, thus maximizing both production output and customer satisfaction. As the industry embraces these innovations, the role of DTF technology will likely continue to grow and influence trends in custom apparel.

Advantages of DTF Technology Over Traditional Methods

The emergence of DTF printing has revolutionized the garment decoration landscape, offering significant advantages over traditional printing methods. Unlike screen printing, which can be labor-intensive and costly, DTF transfers streamline the process by allowing rapid production without sacrificing quality. The versatility of DTF technology also means it can effortlessly cater to both small runs and larger productions, which is essential for businesses looking to remain agile and responsive to market trends.

In addition to efficiency, DTF printing provides unmatched detail and color vibrancy. This is crucial as consumers increasingly seek unique and eye-catching designs that reflect their personal styles. Moreover, DTF transfers do not require pre-treatment of fabrics, further simplifying the production workflow. By reducing operational complexities, companies can allocate resources more effectively, ensuring they remain competitive in a fast-evolving print industry.

Sustainability and DTF Transfers: A Greener Choice

Sustainability is a pivotal issue in today’s print industry, and DTF transfers represent an environmentally friendly alternative to traditional processes. Traditional printing methods often involve chemical dyes and excessive waste, significantly impacting the environment. In contrast, DTF technology minimizes the use of harmful materials and promotes more sustainable manufacturing practices. By utilizing water-based inks and reducing waste, businesses can not only meet consumer demand for eco-friendly products but also contribute positively to environmental preservation.

Moreover, companies adopting DTF printing can effectively reduce their carbon footprints while enhancing their brand image. As more consumers seek products that align with their values, businesses that prioritize sustainable practices are in a prime position to capture new markets. By integrating DTF technology, companies demonstrate their commitment to sustainability, simultaneously appealing to environmentally conscious consumers and leading the charge towards a greener future in the print industry.

The Economic Impact of DTF Printing on the Garment Industry

The economic implications of DTF printing on the garment industry are profound, as this technology offers cost-effective solutions for businesses navigating fluctuating demand. DTF transfers require minimal setup costs compared to traditional printing methods, making them accessible to both startups and established organizations. This lower barrier to entry allows more businesses to experiment with custom apparel offerings without incurring significant financial risk.

In addition, the fast turnaround capabilities of DTF printing contribute to improved cash flow for businesses. By allowing for rapid processing of bulk orders and customization requests, companies can tap into immediate consumer trends. They can keep production running efficiently, fulfilling orders quickly, thereby enhancing customer service and loyalty. The economic viability of DTF transfers positions it as a powerful tool for companies aiming to thrive in today’s competitive landscape.

DTF Transfers and the Expansion of Personalized Products

As consumer demand for personalized products grows, DTF transfers offer a practical solution that enables brands to provide customized options at scale. This technology empowers businesses to create unique designs tailored to individual customer preferences, facilitating a more engaging shopping experience. Whether it’s creating a signature T-shirt for an event or unique merchandise for a brand, DTF printing opens new avenues for creativity and brand expression.

Moreover, incorporating DTF transfers into product offerings allows businesses to stand out in crowded marketplaces. Today’s consumers value personalization and are willing to invest in products that reflect their individual identities. By leveraging DTF technology, brands can capture this demographic effectively, further driving sales and deepening customer relationships. The ability to effortlessly reproduce intricate designs links directly to both innovation and consumer engagement in the evolving print industry.

Exploring the Versatility of DTF in the Print Industry

The versatility of DTF transfers extends far beyond apparel; it also holds significant potential for various applications within the print industry. This technology is suitable for a wide range of materials, making it perfect for printing on items such as bags, caps, and more. By diversifying their product offerings, businesses can utilize DTF transfers to cater to different customer segments, capitalizing on trends across multiple markets.

Furthermore, DTF printing is conducive to a variety of artistic styles, from photo-realistic images to bold graphics, allowing designers to experiment with different aesthetics. This adaptability not only attracts a broader audience but also supports innovative marketing strategies. By showcasing their capacity for diverse decorative possibilities, businesses can enhance their brand identity while remaining relevant in an ever-changing print landscape.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct-to-Film transfers, are a printing technique that involves printing designs onto a special film, which is then heat-pressed onto garments. This method allows for vibrant, high-quality prints on various fabrics, making it a popular choice in the custom apparel market.

How do DTF transfers compare to traditional printing methods in the print industry?

Compared to traditional printing methods, DTF transfers offer better vibrancy, durability, and flexibility. They enable printers to produce complex designs with ease, while also reducing waste and minimizing the use of harmful chemicals, making them a sustainable option in the print industry.

What are the sustainability benefits of using DTF printing technology for garment decoration?

DTF printing technology promotes sustainability by reducing the use of harmful materials and minimizing waste generated during production. As businesses adopt DTF transfers, they contribute to more environmentally friendly practices in the print industry.

Can DTF transfers be used for full-color designs on all types of garments?

Yes, DTF transfers can be used to create full-color designs on various types of garments, including T-shirts, hoodies, and more. This versatility makes them ideal for businesses looking to offer custom apparel with unique and detailed graphics.

What are the advantages of using DTF transfers for quick turnaround times?

DTF transfers allow businesses to achieve quick turnaround times due to their ease of application and efficient printing process. This is crucial in today’s fast-paced market, where customer demands can change rapidly, enabling companies to respond efficiently to order requests.

How is the DTF printing market expected to grow in the coming years?

Analysts project significant growth in the DTF printing market through 2030, driven by increasing demand for individualized custom apparel and advancements in DTF technology. As more businesses adopt this method, it is expected to reshape the landscape of the print industry.

| Key Points | Details |

|---|---|

| Introduction | DTF transfers are revolutionizing the print industry by improving apparel printing techniques. |

| Market Growth | The DTF printing market is rapidly expanding, driven by demand for custom apparel. |

| Technological Advantages | DTF printing offers superior quality, flexibility, and quick turnaround times. |

| Sustainability | DTF is an eco-friendly option that reduces waste and harmful chemicals compared to traditional methods. |

| Market Implementation | Key players are adopting DTF technology to improve efficiency and meet bulk order demands. |

| Conclusion | DTF transfers enhance quality and sustainability, making them crucial for the future of printing. |

Summary

DTF transfers are revolutionizing the print industry by enhancing print quality, efficiency, and sustainability. This game-changing technology allows businesses to meet the rising consumer demand for customization while maintaining impressive durability in garment prints. As DTF transfers continue to gain traction, they signify a transformative shift in how apparel printing is approached, highlighting the industry’s commitment to innovation and eco-friendliness. Embracing DTF technology not only places companies at the forefront of market trends but also ensures they remain competitive in a fast-evolving landscape.