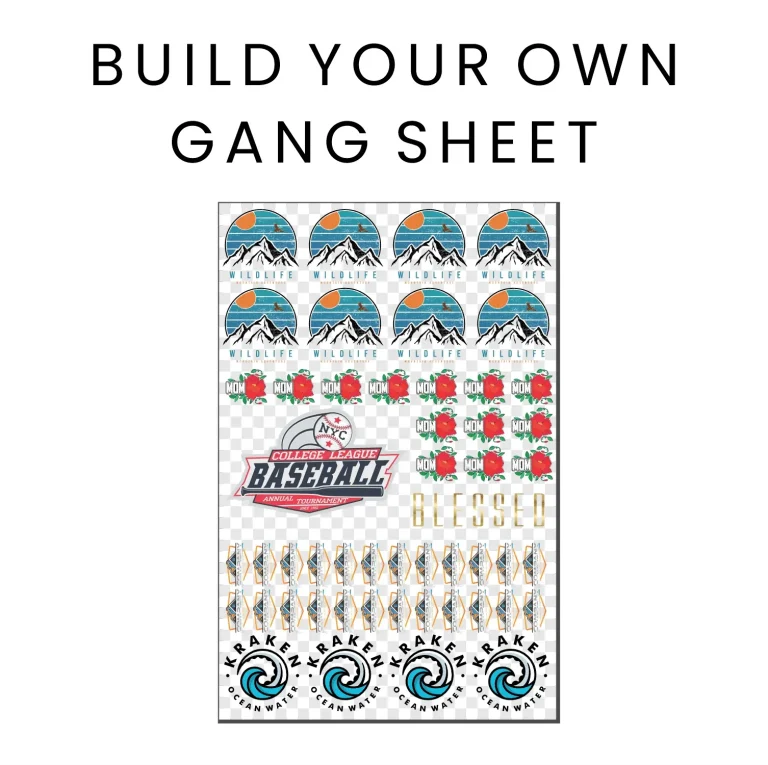

The **DTF Gangsheet Builder** is transforming the landscape of Direct to Film (DTF) printing, empowering creators with an intuitive solution for developing striking, professional fabric prints. This versatile tool excels in design preparation for DTF, allowing users to optimize their layouts, reduce material waste, and maximize production efficiency. By incorporating essential printing settings for DTF and leveraging high-quality transfer films, users can achieve vibrant colors and intricate details with every print. Furthermore, the DTF Gangsheet Builder simplifies troubleshooting DTF prints, ensuring a smooth production process and high-quality results. Elevate your fabric decoration projects by mastering this innovative builder, setting the stage for sensational printed creations that impress customers and viewers alike.

The Direct to Film printing process, often referred to as DTF printing, is increasingly popular in the garment and fabric decoration industry. With tools such as the DTF Gangsheet Creator, users can seamlessly compile multiple images for longer runs, significantly enhancing their workflow. This innovative software assists in design layout optimization and boosts efficiency, making it an invaluable asset for both enthusiasts and professionals. Moreover, understanding the intricacies of printing configurations tailored for DTF can empower users to achieve superior print quality. By focusing on design preparation, handling of transfer films, and mastering troubleshooting techniques, printmakers can unlock the full potential of this modern printing technology.

Understanding DTF Printing Technology

DTF printing, or Direct to Film printing, is a groundbreaking technique that revolutionizes fabric printing. By utilizing a unique transfer film, this method allows for intricate and vibrant designs to be printed on a variety of materials, including cotton and polyester. DTF printing stands out due to its ability to produce high-resolution images with soft-hand feel, unlike other methods which may leave a stiff or rough texture on the fabric.

The core of DTF technology lies in its printing process, where images are first printed onto a special film using high-quality inks. Once printed, the design is coated with a hot melt adhesive powder, which, when heated, adheres firmly to the fabric. This process not only ensures bright colors but also exceptional durability, making it a preferred choice for apparel manufacturers and DIY enthusiasts alike.

Maximizing Efficiency with the DTF Gangsheet Builder

The DTF Gangsheet Builder is an innovative tool designed to optimize the DTF printing process. By allowing users to compile multiple designs onto a single sheet, it significantly reduces material wastage, making it an economical choice for small businesses and hobbyists. This efficiency paves the way for quicker turnaround times, enabling creators to handle larger orders without compromising quality.

In addition to economic benefits, the Gangsheet Builder promotes organization and improves workflow. Users can easily manage their designs, ensuring optimal layouts that prevent overlapping and misalignment. By maximizing space on each sheet, print professionals can produce more prints in less time, enhancing productivity and allowing for a faster, more streamlined operation.

Steps for Effective Design Preparation

Proper design preparation is a crucial step in achieving superior DTF prints. The first step involves creating artwork using graphic design software like Adobe Illustrator or CorelDRAW, ensuring your designs are created at a resolution of at least 300 DPI. This high resolution ensures that your prints are clear, vibrant, and professional-looking, meeting the quality expectations of customers.

Additionally, color management plays a vital role in the design process. Using an RGB color profile allows designers to maintain color fidelity across different media. When you prepare your design with these parameters, you’re setting a solid foundation for the DTF printing process, ensuring the final product is as stunning as you envisioned.

Optimizing Printing Settings for DTF

To achieve high-quality DTF prints, configuring your printer settings correctly is paramount. Key settings to focus on include temperature and pressure, typically around 320°F to 350°F for heat presses. Proper adjustments to these settings are essential for ensuring that the ink adheres well to the film and transfers effectively onto the fabric.

Furthermore, conducting test prints on various types of fabric can provide insight into how different materials react to your printer settings. By experimenting with these configurations, you can fine-tune your printing process to achieve the best results, enhancing your overall print quality and efficiency.

Post-Printing Care for Longevity

After completing your DTF prints, it’s critical to allow garments adequate resting time to ensure that the inks fully cure. This patience not only protects the integrity of the prints but also enhances durability, reducing the risk of premature fading or peeling. Faculty in this post-printing care step is essential for maintaining the quality of your work.

When it comes to washing your printed garments, always remember to turn them inside out and use cold water. This method helps in prolonging the life of the prints, allowing your designs to withstand the rigors of regular use. By adopting these care practices, you can ensure that your prints remain as vibrant and appealing as the day they were made.

Addressing Common Troubleshooting Issues in DTF Printing

Troubleshooting issues in DTF printing can be relatively straightforward if you are familiar with common problems that may arise. For example, peeling prints can often be resolved by adjusting the heat or pressure applied during the transfer process. It’s advisable to regularly check your equipment to identify any deviations from optimal performance that could affect the output quality.

Fading prints are another common concern associated with DTF printing. Ensuring that you use high-quality inks and films designed specifically for DTF applications will significantly mitigate this issue. Additionally, maintaining proper washing and care practices can help in sustaining the vibrancy of your prints and extending their lifespan.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it work in DTF printing?

The DTF Gangsheet Builder is a software tool designed for Direct to Film (DTF) printing, allowing users to compile multiple designs onto a single sheet. This functionality maximizes material use, reduces waste, and speeds up the printing process, making it essential for efficient DTF printing.

What are the best practices for design preparation using the DTF Gangsheet Builder?

When preparing designs for the DTF Gangsheet Builder, ensure that your graphics are created at a minimum resolution of 300 DPI and use RGB color settings for accurate color reproduction. This ensures vibrant and high-quality prints once transferred to fabric.

How do I adjust printing settings for optimal results with DTF Gangsheet Builder?

To achieve the best results while using the DTF Gangsheet Builder, adjust your printer settings carefully, particularly the temperature (between 320°F to 350°F) and pressure for the heat press. Testing different settings with various fabrics can help determine the ideal setup for your specific DTF printing projects.

What common troubleshooting tips can I use for issues with DTF prints created with the Gangsheet Builder?

Common issues include peeling or fading of prints. For troubleshooting, check your printer settings, ensure proper adhesion by pre-treating certain fabrics, and consult a troubleshooting guide specific to the DTF process to help resolve printing problems effectively.

How can I maintain high-quality results when using the DTF Gangsheet Builder?

To maintain high-quality results, use premium DTF transfer films and inks, and make sure your printing and heat press equipment are well-maintained and calibrated. Consistent upkeep of your printers contributes significantly to achieving the best outcomes for your DTF prints.

Are there resources available to help me improve my skills with the DTF Gangsheet Builder?

Yes, there are numerous resources available, including online tutorials, community forums, and workshops focused on DTF printing. Engaging with these materials can provide valuable insights and updates on best practices for using the DTF Gangsheet Builder effectively.

| Key Point | Description |

|---|---|

| Efficiency | Enables compilation of multiple designs on a single sheet, reducing waste and speeding up production. |

| Versatility | Supports various fabric types, providing broad application for creative garment decoration. |

| High-Quality Results | Utilizes specialized inks for vibrant colors and intricate details, ensuring excellent print quality. |

| Design Preparation | Use graphic software with a minimum resolution of 300 DPI to ensure clarity. |

| Using the Gangsheet Builder | Import designs with proper layout to prevent overlap and maximize material use. |

| Printing Settings | Adjust temperatures (320°F to 350°F) and pressure for optimal adhesion and durability. |

| Post-Printing Care | Let printed garments rest before washing and wash inside out to prevent fading. |

| Troubleshooting | Be familiar with common issues like peeling; maintain a troubleshooting guide. |

| Continuous Learning | Engage in communities and workshops for skills development and industry updates. |

Summary

DTF Gangsheet Builder is a powerful tool that revolutionizes the fabric printing process by enabling creators to compile designs, optimize material use, and enhance print quality. By following the best practices outlined above, anyone can achieve stunning results in their printing projects. From efficient design preparation to meticulous post-print care, each step is crucial for ensuring vibrant and durable prints. Leveraging the capabilities of the DTF Gangsheet Builder not only streamlines workflow but also opens up a world of creative possibilities in garment decoration.