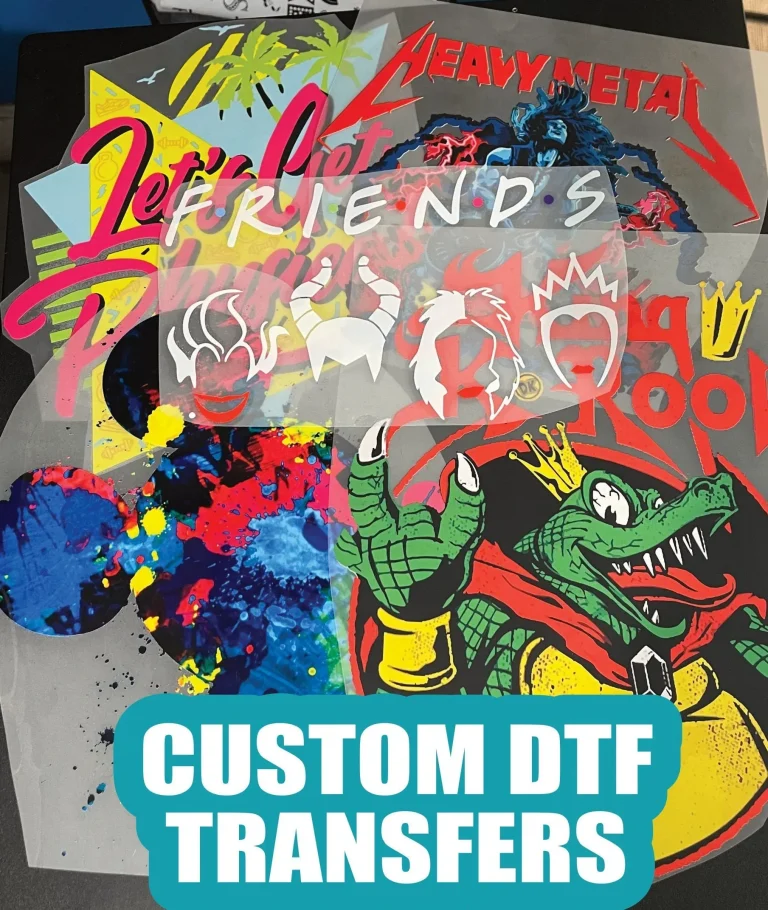

DTF transfers, or Direct-to-Film transfers, are making waves in the realm of heat transfer printing, offering a dynamic and versatile method for transferring high-resolution designs onto various fabrics. This innovative printing technique provides incredible detail and vibrancy, enabling creators to craft stunning custom DTF designs that cater to diverse fashion trends. With the rise of DTF printing techniques, businesses are now able to respond to consumer demands with greater flexibility, allowing for unique DTF transfer sizes tailored to individual preferences. As garment decoration trends evolve, understanding the capabilities and advantages of DTF transfers becomes essential for anyone looking to stand out in the competitive apparel market. Join us as we explore how to effectively utilize DTF transfers in your designs for eye-catching results.

Known variably as Direct-to-Film prints, these transfers bring a fresh perspective to custom garment decoration. This technique emphasizes the use of specialized films to create vibrant images that seamlessly adhere to fabric, setting a new standard in heat transfer applications. With a multitude of options for DTF transfer sizes, designers can now customize their artwork to meet specific garment dimensions and style preferences. As trends in garment decoration pivot towards more personalized apparel, using high-quality DTF printing techniques can maximize design visibility while ensuring durability. Join us in uncovering the transformative impact of DTF transfers in the textile industry.

Understanding DTF Printing Techniques

Direct-to-Film (DTF) printing represents a groundbreaking method within heat transfer printing, efficiently merging innovative technologies with creative expression. This technique enables the reproduction of intricate designs with vibrant colors on a range of fabrics, such as cotton, polyester, and blends. Central to its effectiveness is the layer of powdered adhesive applied to the transfer film that aids in the heat transfer process, ensuring designs adhere effectively while maintaining their detail and color saturation.

The essence of DTF printing techniques lies in their versatility and ease of use. Manufacturers have developed specialized inks and films that make this process suitable for both small-scale operations and larger commercial businesses. Users can achieve high-quality, full-color prints with remarkable detail, elevating any garment’s visual appeal and market value. This capability makes DTF printing an attractive option for numerous applications, from custom apparel to promotional items.

The Importance of DTF Transfer Sizes

The size of DTF transfers significantly impacts both aesthetic appeal and functional performance within the garment decoration realm. Large transfers are often used to create bold statements, perfect for promotional items or eye-catching apparel designs. However, oversized transfers may obscure intricate design elements, leading to a potential loss of detail. On the other hand, smaller transfers allow for more discreet applications that can complement garment designs without overwhelming the overall look.

Moreover, durability is closely linked to DTF transfer sizes. A well-sized transfer, covering approximately 20-30% of the garment’s surface, ensures better adherence and longevity. Oversized transfers face increased risks of cracking or peeling over time, while transfers that are too small may not provide adequate visibility or durability. Striking a balance is vital, as it allows designs not only to resonate visually but also to endure regular wear and washing.

Current Trends in DTF Transfer Sizes

As we approach 2024, the trend towards customization in the apparel market is reshaping the landscape of DTF transfers. Consumers are now leaning towards unique, tailored sizes and placements that express their individual styles. This growing demand prompts brands to adapt quickly to various customization options, offering consumers the ability to select the size that resonates most with their needs, whether through large logo placements or delicate accents on sleeves.

Pre-sized templates provided by companies like Printify and DTF Superstore are also becoming more prominent, streamlining the customization process. These templates simplify decision-making for users, allowing them to select sizes efficiently that meet current fashion trends. This approach not only enhances the user experience but also aids in balancing visibility and comfort, vital components in modern design considerations.

Advancements in DTF Production Techniques

The advancements in production techniques for DTF transfers are heavily geared towards enhancing precision and quality. With innovations in cutting technology, manufacturers can achieve more precise size variations without compromising the integrity of the design. This precision ensures that custom DTF designs maintain their quality, regardless of size, granting designers greater creative freedom while elevating the finished product.

Additionally, the development of stronger adhesive materials significantly boosts the durability and longevity of DTF transfers. Enhanced adhesives are designed to withstand rigorous use and multiple washes, creating options for both large and small transfer designs. These innovations enable businesses to offer reliable products to consumers, catering to both aesthetic desires and practical needs.

Choosing Materials for DTF Transfers

Selecting the right materials for DTF transfers is crucial for achieving the desired results in garment decoration. Brands increasingly opt for eco-friendly materials, responding to a growing consumer demand for sustainable practices in fashion. Utilizing water-based inks diminishes environmental impact and offers safer application processes for both manufacturers and consumers.

Moreover, biodegradable films are emerging as a sustainable alternative to traditional materials. By choosing these films, brands align with global initiatives aimed at reducing waste in the textile industry. As consumers become more environmentally conscious, the use of such materials can also enhance brand reputation, appealing to a market segment that prioritizes sustainability in their purchasing decisions.

Educational Resources for Effective DTF Practices

Navigating the complexities of DTF transfers requires access to quality educational resources. Numerous platforms, including Printify and DTF Superstore, furnish users with comprehensive guides and tutorials aimed at enhancing understanding of DTF printing techniques. These resources cover everything from basic design principles to advanced application methods, ensuring that both novices and seasoned professionals can benefit.

In addition to practical guides, educational content addresses common queries that arise in the process of sizing and transferring DTF designs. By equipping professionals with the right knowledge, they can effectively implement best practices that ensure the quality and longevity of their garments, ultimately fostering greater customer satisfaction in an increasingly competitive market.

Frequently Asked Questions

What are DTF Transfers and how do they work in heat transfer printing?

DTF Transfers, short for Direct-to-Film, involves printing high-quality graphics onto a special film before transferring it onto fabric using heat. This process includes designing the artwork, printing it with a DTF printer, applying a powdered adhesive, and finally using a heat press to adhere the design to the garment. This technique is great for achieving vibrant colors and intricate designs on various fabric types.

Why is the size of DTF Transfers important in garment decoration?

The size of DTF Transfers is crucial for both aesthetic impact and durability. Larger transfers make bold visual statements but may lose intricate detail, while smaller transfers can add subtlety and better placement options. Ideally, a transfer should cover about 20-30% of the garment surface for optimal visibility without compromising comfort or durability.

What customization trends are influencing DTF Transfers in today’s market?

Current trends show a strong consumer preference for personalized, custom DTF designs. Shoppers increasingly desire unique sizes and placements, which has prompted brands to adopt pre-sized templates for DTF transfers. These templates simplify the customization process, making it easier for customers to select styles that fit their individual taste.

How do current industry guidelines affect DTF Transfer sizes?

Industry guidelines recommend that DTF Transfer sizes should balance visibility, comfort, and functionality. Designers should keep their transfer dimensions in line with these guidelines to avoid compromising movement or comfort while ensuring the design remains prominent and visually effective.

What technological advances are enhancing DTF printing techniques?

Recent advancements in DTF printing include precision cutting technologies that allow for more accurate size variations without sacrificing quality. Additionally, enhanced adhesives now provide stronger bonds for DTF transfers, ensuring they withstand washing and wearing while maintaining their visual appeal.

What materials are used in DTF Transfers that support eco-friendly practices?

Modern DTF Transfers are increasingly utilizing eco-friendly materials such as water-based inks and biodegradable films. These materials align with consumer preferences for sustainability and contribute to reducing waste and harmful chemical usage in the garment decoration industry.

| Key Points |

|---|

| DTF Transfers involve printing designs onto a special film for heat transfer onto fabrics, encompassing design creation, printing, adhesive application, and heat pressing. |

| Size significantly affects visual impact, durability, and customization—larger designs make bold statements, while smaller transfers offer subtle elegance. |

| Current trends emphasize personalized apparel, with pre-sized templates gaining popularity for seamless customization options. |

| Advancements in production techniques enhance precision in cutting and adhesive quality, improving transfer durability and performance. |

| Eco-friendly materials such as water-based inks and biodegradable films are becoming integral in DTF printing to meet sustainable consumer demands. |

| Extensive resources are available online to guide both newcomers and experienced users in best practices for DTF transfers. |

Summary

DTF Transfers are a groundbreaking technology in the garment decoration industry, emphasizing the importance of size in achieving the desired design aesthetic and performance. As trends shift towards personalization, understanding how size impacts durability and visual impact is crucial. Larger designs can create bold statements while smaller transfers allow for discreet elegance. By leveraging advancements in production technology and eco-friendly materials, brands can meet consumer demands for sustainability and creativity. Staying informed about these trends and techniques will empower brands to maximize the potential of DTF transfers, catering to the unique tastes of their clientele.