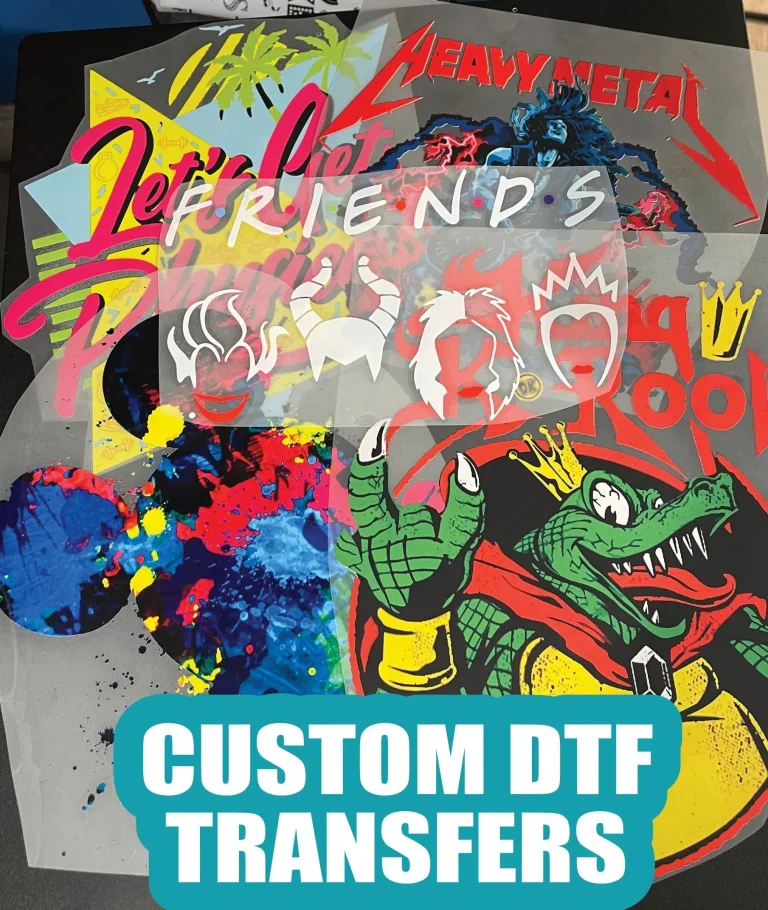

DTF transfers, or Direct-to-Film Transfers, have revolutionized the world of custom apparel printing in recent years. This innovative technique allows for the creation of vibrant, high-quality designs that can easily be transferred onto a wide variety of fabric types, making it a favored choice among both hobbyists and professionals. By utilizing advanced DTF printing technology, users can enjoy the advantages of versatility in garment printing methods, ensuring that everything from t-shirts to tote bags can be beautifully adorned with custom prints. The DTF printing process also caters to beginners, who find it straightforward to execute with the right DTF transfer equipment and a bit of creativity. With this guide, you’re about to discover the exciting possibilities of DTF transfers and how they can elevate your custom printing projects.

In the realm of custom fabric printing, techniques like Direct-to-Film and Heat Transfer Printing are gaining considerable attention. DTF, as it’s commonly referred to, stands out for its ability to produce sharp, detailed images on various textiles, which appeals to both small businesses and individual creators. Given the rising popularity of garment decoration methods, this approach has become synonymous with high-quality apparel design production. With the right printing equipment and materials, anyone can dive into the world of DTF transfer printing, thus enjoying a rewarding creative pursuit that merges artistry and technology. In this overview, we will delve deeper into how DTF transfers work and their distinct advantages in the printing industry.

Understanding the DTF Printing Process

The Direct-to-Film (DTF) printing process involves a unique set of steps that differentiate it from traditional printing methods. It begins with designing an image using graphic design software, where users can unleash their creativity. Once the design is finalized, it’s printed onto a specialized DTF film using a dedicated DTF printer that utilizes specific inks for vibrant colors and superior detail. This step is crucial, as the choice of high-quality DTF inks directly affects the outcome of the final product. Alongside this, applying an adhesive powder while the ink is still wet solidifies the bond between the ink and the film, ensuring longevity and durability.

After the printing phase, the next stages are equally essential. Curing the ink and adhesive through a heating process prepares the transfer for application. This step ensures that the inks are properly set, which leads to enhanced wash fastness and wearability. Once cured, the last phase involves heat transferring the design onto the chosen garment using a heat press, where consistent temperature and pressure create a flawless finish. This systematic approach to DTF printing not only optimizes the quality of prints but also enhances productivity, attracting many custom apparel businesses.

Benefits of Using DTF Transfers for Custom Apparel

DTF transfers bring a multitude of benefits to the world of custom apparel printing, making them an appealing choice for both novices and seasoned professionals. One of the primary advantages is the versatility of fabric compatibility. Whether it’s cotton, polyester, or blends, DTF printing adapts seamlessly, allowing users to create custom designs on a variety of garments, including t-shirts, bags, and more. This capability opens new avenues for creativity, enabling fashion brands to diversify their offerings.

Furthermore, the durability of DTF prints is unmatched. Unlike some traditional methods, these transfers retain their color vibrancy even after numerous washes, making them perfect for items intended for frequent wear. Entrepreneurs and small businesses can benefit from the quality and cost-effectiveness of DTF transfers. As a production method, it provides an efficient way to fulfill orders without sacrificing the integrity of the designs, ensuring customer satisfaction and repeat business.

Essential Equipment for DTF Printing Success

To successfully venture into DTF printing, acquiring the right equipment is paramount. First and foremost, you will need a dedicated DTF printer that is compatible with specialized inks designed for this process. Investing in a high-quality printer ensures that you achieve the best possible results in terms of color accuracy and print resolution. Moreover, a reliable heat press is essential for transferring designs correctly, applying the necessary heat and pressure to ensure effective adhesion.

Apart from the printer and heat press, you’ll also require DTF transfer film, which acts as a canvas for your designs. This film must be chosen carefully; using inferior quality film can lead to poor transfer results. Additionally, having the right software for graphic design is invaluable, as it allows you to create stunning visuals that can leverage the full capability of DTF transfers. Together, these tools form the backbone of a successful DTF printing operation.

Step-by-Step Guide to Creating DTF Transfers

Embarking on the DTF transfer journey is an exciting experience, and following a systematic approach can help streamline the process. First, begin with design creation using graphic design software that you are comfortable with; Adobe Illustrator is a favorite among professionals, but there are free alternatives for beginners too. Once your design is crafted, it gets printed onto the DTF film using a compatible printer. Remember to ensure the ink is DTF approved, as this is crucial for achieving high-quality results.

The next steps involve applying the adhesive powder to the wet ink and curing it through heat before transferring it onto your chosen garment. It’s important to adjust temperature and pressure settings of your heat press according to the fabric and film specifications to achieve the best results. By meticulously following each step, from design creation to heat transfer, you can ensure that your custom apparel not only looks great but lasts long, making your efforts worthwhile.

Exploring Cost Considerations for Starting a DTF Printing Business

When considering entering the DTF printing market, it’s essential to evaluate the financial implications. The initial setup costs can vary greatly, depending on the quality of DTF transfer equipment you choose. A budget between $2,000 to $5,000 is typical, which includes a DTF printer, heat press, and necessary supplies. While this investment might feel substantial, it is vital to weigh it against the potential profits that can be generated through high-quality custom apparel.

Moreover, DTF transfers tend to offer a higher return on investment due to the durability of the prints and the ability to cater to a versatile market. As your business grows, the cost per item decreases, ultimately leading to higher profitability. Understanding these financial aspects early on can help you build a sustainable DTF printing venture that not only meets market demands but also fulfills your artistic ambitions.

Applications of DTF Transfers in Various Industries

DTF transfers have found widespread applications across different industries, primarily due to their versatility in creating custom apparel. The primary use is in the fashion sector, where designers and brands tailor t-shirts, hoodies, and caps with unique prints that resonate with their audience. This capability empowers businesses to market exclusive collections that attract various consumer demographics, from casual wear to high-fashion items.

Beyond apparel, DTF transfers extend their utility into promotional merchandise and corporate branding projects. Companies leverage DTF printing for creating customized gifts and event merchandise that enhance brand visibility and engagement. Additionally, hobbyists employ DTF techniques for personal projects and gifts, revealing its potential for creative expression and personalized designs. Such diverse applications ensure that DTF printing remains a relevant and sought-after solution in the modern printing landscape.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, utilize a specialized film to print intricate and colorful designs. In the DTF printing process, designs are printed onto the film with special inks, which are then heat pressed onto various types of fabrics, resulting in vibrant and lasting prints suitable for custom apparel.

What equipment do I need to get started with DTF transfer printing?

To embark on DTF transfer printing, you will need essential equipment including a dedicated DTF printer to handle specialized inks, DTF transfer film as the base for your designs, and a heat press to transfer the ink from the film to the garment. This setup is crucial for achieving high-quality custom apparel printing.

What are the advantages of using DTF printing over other garment printing methods?

DTF printing offers several advantages including versatility across various fabric types, exceptional print quality and durability, and ease of use for beginners. Unlike screen printing and DTG, DTF transfers maintain vibrant colors even after multiple washes, making them ideal for durable apparel.

Can I use DTF transfers on different fabric materials?

Yes, one of the key advantages of DTF transfers is their compatibility with multiple fabric types. This method allows for effective printing on materials like cotton, polyester, and blends, making it a versatile choice for creating custom apparel for various applications.

What are the costs associated with starting a DTF transfer printing business?

Starting a DTF transfer printing business typically requires an investment ranging from $2,000 to $5,000. This cost covers the necessary equipment such as a DTF printer, heat press, and transfer film. While the initial costs may seem high, the quality and durability of DTF prints often lead to a good return on investment.

What tips can you offer for beginners interested in the DTF printing process?

For beginners in DTF printing, it’s important to invest in quality equipment and familiarize yourself with the DTF printing process. Start with simple designs using graphic software, apply DTF powder adhesive correctly, and ensure the heat settings on your press are optimal for the film and fabric being used. This will help achieve the best results for your custom apparel projects.

| Aspect | Description |

|---|---|

| What are DTF Transfers? | Printing method that transfers designs from a film to fabric. |

| Advantages | 1. Versatility: Compatible with various fabrics (cotton, polyester, etc.). 2. Quality and Durability: High-quality, long-lasting prints. 3. Ease of Use: Simple for beginners, quick to learn. |

| Getting Started | Key equipment needed includes DTF printer, DTF film, and heat press. Also requires graphic design software (Adobe Illustrator or GIMP). |

| Step-by-Step Process | 1. Create design 2. Print on DTF film 3. Apply adhesive 4. Cure ink 5. Heat press onto fabric |

| Cost Considerations | Initial costs range from $2,000 to $5,000 for equipment and supplies, but offer excellent ROI through durability. |

| Common Applications | Used in custom apparel, promotional merchandise, and creative projects. |

| Recent Developments | Rapid growth of DTF printing due to improved technology and affordable options for small businesses and individuals. |

| Final Thoughts | Starting with DTF transfers offers a rewarding experience with its diverse applications and impressive quality. |

Summary

DTF transfers represent a revolutionary approach to custom apparel printing that is accessible and versatile for beginners and experts alike. This method allows for high-quality, durable prints that can be applied to a variety of fabrics, making it a powerful tool for personal and business projects. With relatively simple equipment needs and an affordable entry point, entrepreneurs can create stunning products while hobbyists can enjoy crafting unique designs. As technology progresses and costs decrease, DTF transfers are poised to further transform the printing landscape, offering endless possibilities for creativity and profitability.