In the dynamic world of consumer products, UV DTF transfers are emerging as an innovative solution for personalized printing in the fashion industry. This cutting-edge DTF printing technology combines digital precision with vibrant colors, allowing for the creation of custom apparel that truly reflects individual styles. As businesses increasingly seek sustainable printing methods, UV DTF transfers not only meet the demands for high-quality personalization but also promote eco-friendly practices. By enabling the production of intricate designs on various surfaces, this technology is reshaping the landscape of fashion personalization for both creators and consumers. Discover how UV DTF transfers are revolutionizing the way we think about customized products and what this means for the future of consumer engagement.

In the realm of innovative print solutions, the concept of UV DTF transfers represents a pivotal shift towards personalized manufacturing. Known for its ability to create custom designs with exceptional quality, this Direct to Film printing approach caters to the growing demand for tailored items in today’s market. As companies strive for more sustainable printing practices, UV DTF emerges as a viable alternative, providing both versatility and durability in custom apparel. This technology not only enhances the aesthetic appeal of products but also aligns with the contemporary trend of fashion personalization. Understanding the principles behind UV DTF will illuminate its potential impact on the future of personalized consumer experiences.

Understanding UV DTF Transfers and Their Impact

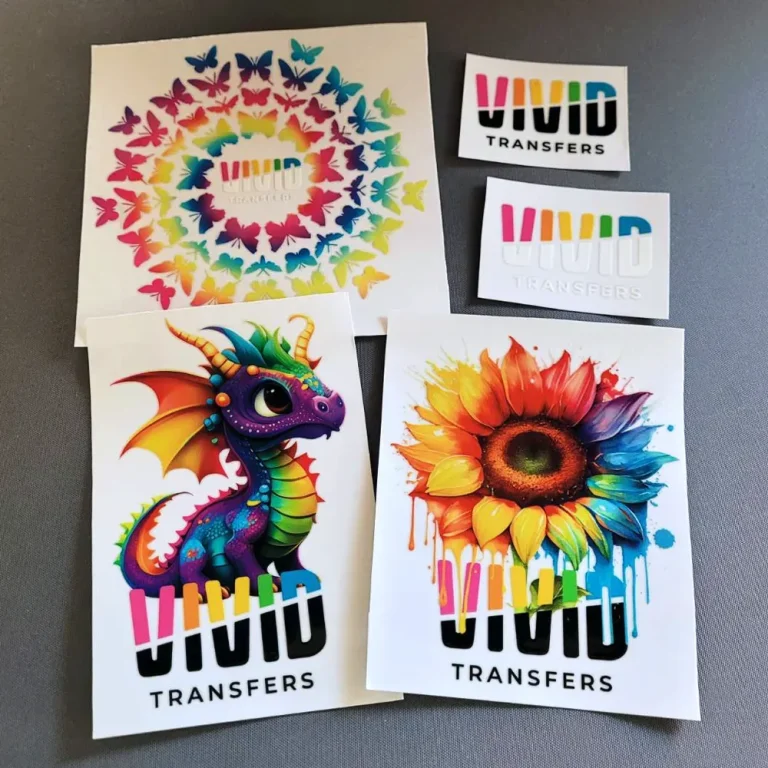

UV DTF (Direct to Film) transfers mark a significant evolution in the field of personalized printing. By combining innovative technology with traditional printing processes, UV DTF allows for detailed designs to be printed on various surfaces, such as apparel, wood, and plastics. This capability not only enhances the creativity involved in custom apparel production but also ensures vibrant, long-lasting colors that resist fading and wear. As a result, businesses can provide unique, high-quality products that align with the increasing consumer demand for customization.

The key advantage of UV DTF technology lies in its versatility, enabling artists and designers to create intricate graphics that reflect consumer preferences. Unlike older methods like screen printing, which often restrict color usage and detail, UV DTF offers the freedom to experiment with gradient images and complex patterns. This level of personalization meets the growing trend of fashion personalization, where consumers crave unique items that express their individuality and style.

Recent Innovations in DTF Printing Technology

The past few years have seen rapid advancements in DTF printing technology, significantly enhancing the quality and speed of production. Modern printers equipped with UV DTF capabilities can manage complex graphic designs with ease, making it easier for businesses to respond to consumer trends quickly. As small and medium enterprises seize on this technology, they find an effective solution for producing high-quality custom apparel while keeping costs manageable.

These technological improvements also promote sustainable printing practices. For instance, UV curing inks require less energy and produce fewer emissions compared to traditional methods, appealing to brands and consumers who prioritize eco-friendly options. As sustainability becomes more critical in the arena of fashion and manufacturing, adopting advanced DTF printing technology positions businesses at the forefront of this crucial shift.

The Market Surge for Custom Apparel Using UV DTF Transfers

The market for customized clothing is experiencing a transformation thanks to the increasing popularity of UV DTF printing. Businesses adopting this method can deliver on-demand personalized products, catering to the fast-paced fashion industry which thrives on trends and timely responses to consumer desires. This flexibility has prompted a surge in the production of unique, customized apparel, positioning brands favorably in a competitive market.

Moreover, as consumers shift towards shopping experiences that offer personalization, the need for rapid production cycles has become paramount. UV DTF transfers allow for quicker turnarounds without sacrificing quality, thus enhancing customer satisfaction. With growing interest in custom fashion items, companies leveraging this technology are not only meeting market demands but also paving the way for future innovations in apparel customization.

Sustainability in UV DTF Printing

As environmental concerns take center stage in the fashion industry, UV DTF printing stands out for its sustainable benefits. This method minimizes waste and reduces energy consumption, making it a more responsible choice for businesses committed to eco-friendly practices. Inks used in this process are typically designed to be low in volatile organic compounds (VOCs), further contributing to healthier production environments and safer products for consumers.

Brands leveraging UV DTF technology are positioned to appeal to environmentally conscious consumers who prefer sustainable options. By highlighting their commitment to green practices, businesses can cultivate loyalty among customers who are increasingly making purchasing decisions based on sustainability. In addition to meeting consumer demands, this approach enhances brand reputation and opens opportunities for collaborative marketing efforts focused on conscious consumerism.

Navigating Challenges in the UV DTF Printing Landscape

Despite the remarkable progress seen in UV DTF printing technology, several challenges remain on the horizon. One of the primary issues is ensuring the quality of inks used in production. Manufacturers must consider sustainable ink alternatives to minimize the negative impact on the environment. Additionally, as UV DTF technology evolves, workers need ongoing training to stay proficient with newer systems and processes.

Adapting to these shifts requires a commitment from businesses to invest in education and resources, fostering an informed workforce capable of embracing change. By prioritizing skill development and sustainability, companies can not only navigate the challenges of UV DTF printing but also position themselves as innovative leaders in the competitive landscape of personalized apparel.

The Future of Personalization with UV DTF Technology

The future of product personalization is inherently intertwined with the advancements in UV DTF technology. As this method continues to refine the way businesses approach customization, it opens new avenues for artistic expression and consumer engagement. From apparel to home decor, the ability to produce high-quality, personalized items will be pivotal in responding to evolving market demands.

Furthermore, as integration between UV DTF printing and artificial intelligence progresses, businesses will benefit from enhanced efficiency and creativity in design processes. This convergence will likely yield a surge in unique, user-generated content, fostering an even deeper connection between brands and their customers. Embracing these innovations will be essential for businesses aiming to thrive in a future shaped by personalization.

Frequently Asked Questions

What are UV DTF transfers and how do they enhance personalized printing?

UV DTF transfers utilize innovative Direct to Film printing technology to create high-quality, custom prints on various materials. By curing inks with UV light, this method offers vibrant, durable graphics that elevate the art of personalized printing, catering to today’s demand for uniqueness in custom apparel and other items.

How do UV DTF transfers contribute to sustainable printing practices?

UV DTF transfers support sustainable printing by using less energy and generating minimal waste compared to traditional methods. Brands can leverage this technology to produce environmentally friendly custom apparel, aligning their practices with consumer preferences for sustainability.

What advantages do UV DTF transfers offer for custom apparel businesses?

UV DTF transfers provide several advantages for custom apparel businesses, including high durability of prints, a broad range of material compatibility, and cost-effectiveness. This technology allows quick production of personalized apparel, meeting the rapid demands of today’s fashion personalization market.

Can UV DTF transfers be used on multiple materials?

Yes, UV DTF transfers are versatile and can be applied to various materials such as textiles, plastics, wood, and metals. This adaptability makes them ideal for personalized products ranging from custom clothing to promotional items.

What role does UV DTF printing technology play in the fashion personalization industry?

UV DTF printing technology is revolutionizing the fashion personalization industry by allowing brands to offer intricate, bespoke designs that resonate with consumers’ individual tastes. Its ability to create high-resolution, durable prints helps businesses cater to the growing trend of customization in fashion.

How does UV DTF technology improve the consumer experience in customization?

UV DTF technology enhances the consumer experience by enabling the creation of detailed, personalized products that reflect individual styles. This innovation not only increases engagement through tailored offerings but also allows consumers to access unique items that stand out in the marketplace.

| Key Points | Details |

|---|---|

| Overview of UV DTF Transfers | A groundbreaking method integrating digital printing with UV curing, producing durable graphics on various materials. |

| Technological Advancements | Improved quality and efficiency in handling complex designs. |

| Popularity Among Businesses | Cost-effective for SMEs, optimizing production time to meet fast-fashion demands. |

| Environmental Considerations | Eco-friendly benefits like lower energy consumption and minimal waste during production. |

| Market Impact and Trends | UV DTF reshaping personalization market, enhancing growth in custom clothing and decor. |

| Future Trends and Developments | AI and automation integration set to enhance design possibilities and production efficiency. |

| Benefits of UV DTF Transfers | Versatile, high durability, cost-effective, and rapid prototyping capabilities. |

| Challenges Ahead | Issues with ink production, sustainable practices, and workforce upskilling remain. |

Summary

UV DTF transfers are revolutionizing the customization landscape by combining innovative technology with consumer creativity. This technique offers versatile applications on various materials while ensuring high durability and cost-effectiveness. As businesses harness the power of UV DTF transfers, they not only meet the rising demand for personalized products but also cater to an environmentally conscious market. Moving forward, the integration of automation and artificial intelligence will further enhance the potential of UV DTF, making it an indispensable tool in the fashion and decor industries.