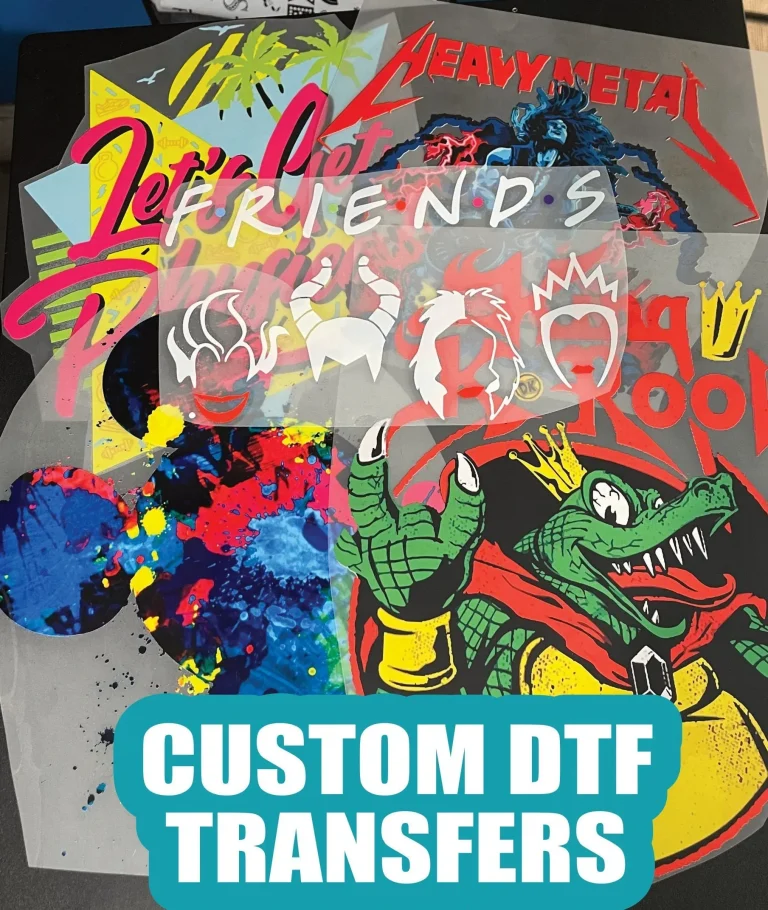

DTF transfers, or Direct to Film transfers, have revolutionized the custom printing landscape, offering an efficient and vibrant solution for textile decoration. This innovative process allows for high-quality prints on various fabric types, making it an ideal choice for garment decorators and small businesses alike. In this guide, we will delve into essential DTF transfer tips, focusing on heat press techniques and how to navigate the diverse DTF transfer sizes available. As more creators look for sustainable options, utilizing eco-friendly DTF inks can enhance both product appeal and environmental responsibility. Join us as we explore how to maximize your DTF transfers and achieve stunning results customized perfectly to your fabric needs.

Direct to Film printing, often abbreviated as DTF, has emerged as a leading technique in textile customization, captivating creators with its ease and effectiveness. This modern printing method enables intricate designs to be transferred onto fabric through a specialized film, providing vibrant colors that capture attention. As we venture into various strategies for optimizing your heat transfer applications, it’s crucial to understand the nuances related to different transfer dimensions. Additionally, leveraging sustainable inks not only benefits the Earth but also aligns your brand with growth trends in conscious consumerism. Explore the exciting world of DTF printing, where creativity meets practicality in custom garment decoration.

Understanding the Basics of DTF Printing

Direct to Film (DTF) printing is a cutting-edge technique designed to elevate custom garment printing. By printing designs onto a specialized film, DTF allows for vibrant and long-lasting prints that adhere well to a variety of fabrics such as cotton, polyester, and blends. This method provides a smoother workflow compared to traditional screen printing, making it particularly appealing for small businesses and home-based decorators. Optimal preparation, including maintaining a high resolution and using vector graphics, is essential for achieving stunning results regardless of the print size.

Moreover, the DTF printing process has gained traction due to its eco-friendly advancements. Innovations in sustainable DTF inks have emerged, catering to a growing demand for environmentally conscious printing solutions. These inks not only provide quality results but also enhance your brand’s reputation as a responsible entity in the textile industry. As consumers become increasingly aware of sustainability, adopting such practices can significantly impact your market appeal and customer loyalty.

Key Tips for Preparing Different Size DTF Transfers

When preparing for various sizes of DTF transfers, the resolution of your design is paramount. High-resolution graphics—preferably at 300 DPI—ensure that details remain crisp, particularly for larger applications where deficiencies become more pronounced. For small prints, such as logos on a shirt pocket, intricate designs may work well; however, for larger designs, simplification of elements is essential to prevent loss of detail and color vibrancy during the transfer process.

Understanding transfer size considerations extends beyond just the artwork; it also involves selecting the appropriate DTF transfer sizes for the intended application. Smaller designs necessitate precision while larger designs benefit from bold, simplified graphics that can withstand the visual scrutiny of larger expanses of fabric. Balancing detail and size ensures that the final product is not only aesthetically pleasing but also retains its quality after repeated use.

Choosing the Right DTF Films and Inks

The selection of DTF films is critical for the success of your print project. Each type of film is designed to accommodate specific fabric types and sizes, so it’s vital to match the film to your application. For instance, larger transfers often call for films that offer enhanced flexibility and adhesion to withstand the rigors of wear and washing. Ensuring proper film selection will lead to creations that boast durability and customer satisfaction.

Equally important is the choice of inks. High-quality DTF inks are essential for achieving the vibrant colors and longevity that customers expect. Opting for cheaper alternatives might save costs initially, but it can result in subpar prints that fade quickly, especially on larger designs that are exposed to more physical stress. Investing in superior inks pays off in the long run, as it preserves the integrity of your prints and enhances your reputation as a reliable service provider.

Mastering Heat Press Techniques for DTF

Heat press technique is pivotal in ensuring the success of DTF transfers, particularly as it relates to size variations. Adjusting temperature settings to fit the size of your transfer can significantly impact adhesion. Larger designs may require an increase in pressing duration or temperature to ensure that the heat permeates the entire surface evenly. Neglecting this adjustment can lead to incomplete transfers, risking future peeling or lifting.

Pressure during the heat pressing process is another critical factor. Consistent and even pressure is key to forming a strong bond between the film and the fabric. Utilizing a heat press with adjustable pressure settings facilitates uniformity across different transfer sizes. Failing to apply proper pressure can result in poor adhesion, especially for larger prints. Mastering this aspect of the DTF process will ensure your transfers not only look good but also stand the test of time.

Caring for DTF Transfers: Importance of Post-Transfer Instructions

Post-transfer care is vital for maintaining the quality of DTF prints over time. Providing customers with clear washing instructions can significantly extend the life of the print. Advising them to wash garments inside out and at lower temperatures helps protect the vibrancy of the print, especially important for larger designs that are more exposed to wear. Such guidance not only enhances the durability of the transfer but also builds trust and reliability with your customers.

Additionally, educating customers on the best practices for garment care conveys professionalism and demonstrates your commitment to quality. By including tips on avoiding harsh detergents and refrain from tumble drying, you equip them with knowledge to preserve their DTF prints. This level of customer service not only fosters loyalty but also encourages repeat business, as satisfied clients are more likely to return and recommend your services to others.

Resources for Optimizing Your DTF Transfer Skills

To continually improve your DTF printing skills, leveraging online educational resources can be a game-changer. Platforms like YouTube are filled with tutorials tailored to the DTF process, demonstrating ideal techniques for different transfer sizes. Visual learners can particularly benefit from these resources, grasping complex concepts through step-by-step demonstrations that illuminate the intricacies of DTF printing.

Furthermore, engaging with online forums dedicated to the DTF community can provide invaluable insights. Connecting with fellow enthusiasts allows for the exchange of tips, troubleshooting advice, and shared experiences that can enhance your understanding and application of DTF printing techniques. The collective knowledge within such communities can serve as an incredible resource, furthering your craft and keeping you abreast of the latest trends in DTF technology.

Frequently Asked Questions

What are the key benefits of using DTF printing for textile customization?

DTF printing, or Direct to Film printing, offers several advantages for textile customization, including vibrant color reproduction, durability, and versatility across various fabric types such as cotton and polyester. This method allows for high-quality prints that maintain detail while being suitable for both large and small designs.

What are some essential DTF transfer tips for achieving high-quality prints?

To ensure high-quality DTF transfers, use high-resolution files (at least 300 DPI), opt for vector graphics for scalability, and select high-quality DTF inks for vibrant colors. Additionally, ensure proper heat press techniques, such as maintaining even pressure and adjusting temperature for different transfer sizes, to achieve optimal adhesion.

How does transfer size impact DTF printing results?

The transfer size significantly impacts DTF printing results. Smaller applications, like logos, can feature intricate designs without losing detail, whereas larger prints require simplified designs to maintain clarity. Preparing designs appropriately for the intended size ensures the best visual impact on the final product.

What sustainable options are available for DTF transfers?

Several sustainable DTF inks and films are now available, catering to eco-conscious consumers. These materials not only reduce environmental impact but also enhance your brand’s image. By incorporating sustainable practices in your DTF transfers, you can appeal to a growing market that prioritizes eco-friendly products.

What considerations should I keep in mind for heat press techniques in DTF printing?

When using heat press techniques for DTF printing, focus on adjusting the temperature, time, and pressure based on your transfer size. Larger transfers may require higher temperatures and longer press times to ensure complete adhesion, while maintaining consistent pressure is crucial to prevent areas of poor adhesion.

How should DTF prints be cared for after application?

To maximize the longevity of your DTF prints, recommend washing garments inside out in cold water and avoiding harsh detergents. This helps maintain the integrity of the print, particularly for larger designs, ensuring they resist fading and wear over time.

| Key Point | Description |

|---|---|

| DTF Printing Basics | Direct to Film (DTF) involves creating designs on a film that are heat transferred onto fabrics, offering vibrant, durable prints. |

| Preparation for Different Sizes | Ensure designs are high-resolution and use vector graphics for clarity across sizes, adapting the complexity for small and large applications. |

| Film and Ink Selection | Choose the right transfer film and high-quality inks to ensure vibrant colors and durability. |

| Heat Press Techniques | Adjust temperature, time, and pressure settings based on the size of the transfer to ensure even adhesion. |

| Post-Transfer Care | Provide washing instructions to maintain print quality, especially for visible larger designs. |

| Additional Resources | Utilize YouTube tutorials and online forums for tips and demonstrations on DTF printing techniques. |

Summary

DTF Transfers have become an essential technique for those looking to customize fabrics efficiently and effectively. Utilizing Direct to Film technology not only enhances the quality of prints but allows for versatility across various applications. A strategic approach involving proper preparation, material selection, heat application, and aftercare can significantly improve the longevity and appearance of your designs. By keeping abreast of advancements in DTF Transfers, users can ensure they stay competitive in the ever-evolving market.