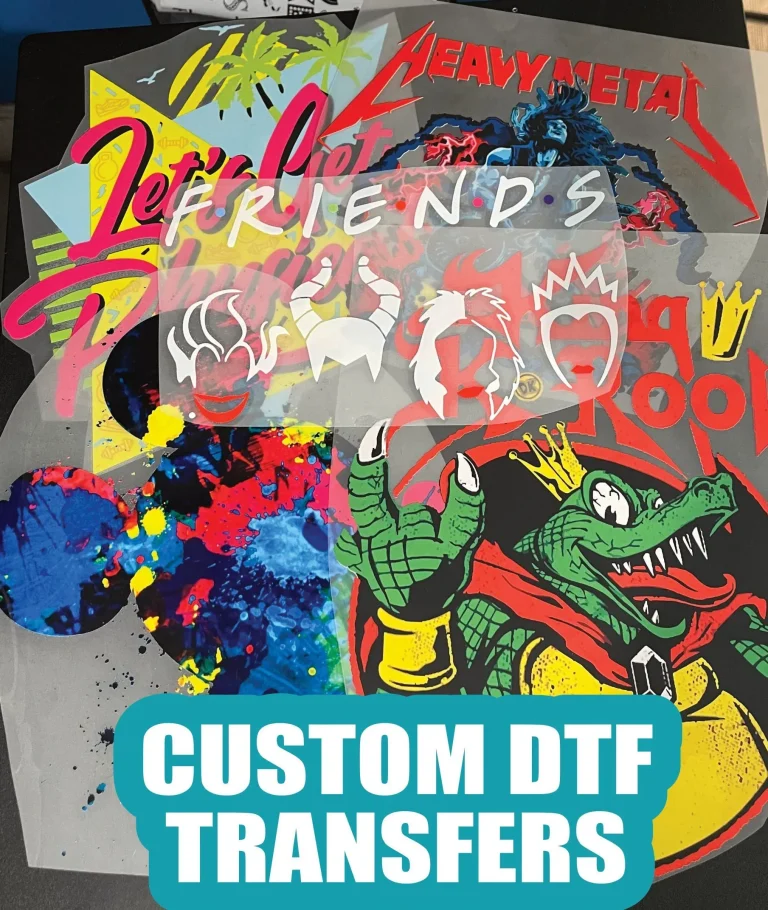

DTF transfers, short for Direct-to-Film transfers, are rapidly changing the landscape of custom apparel printing. This revolutionary technique allows for vibrant, high-quality prints that adhere seamlessly to various fabrics, both light and dark. In our detailed DTF printing guide, we’ll delve into the numerous benefits that DTF transfers offer, including their durability and ease of use, making them ideal for both beginners and seasoned professionals alike. Understanding how to DTF transfer not only empowers you to create stunning designs but also opens the door to exciting creative opportunities in the world of personalized apparel. Join us as we unlock the magic of DTF transfers and explore how you can harness this innovative printing method to elevate your fabric projects.

Direct-to-Film (DTF) transfers serve as a dynamic solution for those venturing into customized textile printing. By utilizing advanced direct-to-film technology, this method ensures that every design is transferred with exceptional clarity and color depth. Whether you’re seeking out a DTF printing guide for beginners or looking into the extensive benefits of this printing approach, the accessibility of DTF printing is apparent. This technique not only streamlines the printing process but also produces resilient finishes that can withstand frequent washing. As we dive deeper into the realm of DTF printing, discover how mastering this technique can transform your creative output into professional-grade results.

Understanding the DTF Transfer Process

Direct-to-Film (DTF) transfers embody a unique blend of technology and creativity, allowing artists and entrepreneurs to produce high-quality designs with remarkable ease. The process begins with printing a design in reverse on a specialized transfer film that captures the intricacies of artwork through vibrant, sharp colors. After printing, hot melt adhesive powder is sprinkled over the wet ink, ensuring that the design adheres perfectly to the fabrics during the pressing phase. This method not only allows for stunning visual outcomes but also caters to a diverse range of fabric types, from cotton to polyester, making it an excellent choice for various apparel projects.

The subsequent step involves heat pressing the film onto the desired fabric, applying precise heat and pressure that activates the adhesive. This crucial phase seals the design onto the fabric, resulting in a durable print known for its longevity and resistance to fading. One of the key advantages of DTF transfers is their versatility; they thrive on both light and dark materials, enabling creators to explore endless possibilities in custom apparel. The seamless integration of technology in DTF printing enhances operational efficiency, making it a go-to method for both hobbyists and professional businesses.

Key Equipment for DTF Printing

To effectively dive into DTF printing, it’s essential to equip yourself with the right tools and materials. The heart of any DTF setup is the DTF printer, which is designed to deliver high-resolution images on transfer film. Additionally, hot melt adhesive powders are integral to the process, as they are essential for ensuring that your designs stick to the fabric during the heat transfer. Different brands of powder yield varying results, encouraging users to experiment to find the best fit for their projects.

Furthermore, transfer films specifically made for DTF printing are crucial to achieving optimal results. These films vary by quality and compatibility, ensuring that the designs remain vibrant and clear once printed onto fabric. Finally, a reliable heat press machine is necessary to provide the precise temperatures and pressure needed for successful transfers. Investing in quality equipment not only enhances the overall printing process but also significantly impacts the final product’s durability and appearance.

Benefits of Using DTF Transfers

The rise in popularity of DTF transfers can be attributed to a myriad of benefits that cater to diverse printing needs. One of the most significant advantages is the ability to reproduce intricate designs with vibrant colors and rich details, ideal for both small-scale operations and large production runs. DTF printing stands out due to its compatibility with various fabric types, allowing businesses to create customized clothing without sacrificing quality or compromise.

Another compelling benefit of DTF transfers is their impressive durability. Unlike other printing techniques that often show signs of wear after numerous washes, DTF prints maintain their visual integrity over time. This feature appeals directly to consumers seeking high-quality apparel that withstands the rigors of daily wear and washing. Furthermore, with DTF’s ease of use and accessibility, even beginners can quickly learn the process, supported by numerous online resources and community groups that provide invaluable guidance.

Common Challenges in DTF Printing

While DTF printing is celebrated for its user-friendliness, several challenges can arise that may hinder the printing process. For instance, achieving proper calibration of the printer and heat press is vital to ensuring quality results. Inconsistent settings can lead to an array of issues, including poor adhesion of the print, color discrepancies, or even equipment malfunctions. Therefore, it’s critical to spend time perfecting these settings before starting any printing projects.

Additionally, the initial setup cost can be a significant consideration for those interested in starting with DTF transfers. While the long-term cost savings can be substantial, the upfront investment in quality printers, heat presses, and other necessary materials can exceed some traditional printing methods such as heat transfer vinyl. Navigating these initial financial hurdles may require careful planning and budgeting; however, the rewards of mastering DTF printing often outweigh the challenges encountered.

Innovative Uses of DTF Transfers

DTF printing technology is not limited to apparel; its applications have expanded into various creative avenues, showcasing its versatility. Home decor has become an exciting space for DTF transfers, with individuals customizing items like pillowcases, tote bags, and wall art to add a personal touch to their living spaces. The ability to create bespoke designs elevates casual decor into something truly unique and reflective of one’s style.

Moreover, the trend of personalized gifting has gained traction with DTF printing. Individuals can craft custom gifts tailored to the recipient’s interests, such as unique t-shirts, hoodies, or memorabilia. This approach not only enhances the emotional value of the gift but also opens new markets for small businesses focused on personalized merchandise. DTF transfers’ adaptability makes them a favored choice for any creative project aimed at individuality and personalization.

Getting Started with DTF Printing: A Beginner’s Guide

For those eager to embark on their DTF printing journey, it’s important to start with a solid foundation. Begin by familiarizing yourself with DTF printing techniques and terminology through dedicated guides and online tutorials. Understanding the basics, from the printing process to the required materials and equipment, will pave the way for successful projects. Additionally, leveraging forums and communities can provide essential insights and troubleshooting tips shared by fellow DTF printing enthusiasts.

Investing time in research and practice is crucial, as mastering the DTF process can open several doors in the custom printing industry. With a commitment to learning, beginners can quickly progress from novice to proficient in DTF printing. The community’s resources, including videos, step-by-step guides, and expert advice, will assist you in refining your skills and elevating your creations to the next level.

Frequently Asked Questions

What are DTF transfers and how do they work?

Direct-to-Film (DTF) transfers are innovative printing methods where designs are printed on a special film before being transferred to fabric using heat and pressure. The process involves printing the design in reverse on transfer film, applying adhesive powder, and then heat pressing it onto the desired material, ensuring vibrant and durable prints.

What are the benefits of using DTF printing for custom apparel?

DTF printing offers numerous benefits, including vibrant color reproduction, durability, and ease of use. It excels in producing intricate designs with many colors, resists fading and cracking after washes, and is accessible even for beginners, thanks to available resources and tutorials.

What equipment do I need to get started with DTF printing?

To start DTF printing, you will need a DTF printer, hot melt adhesive powders, transfer films designed for DTF, and a heat press machine. This combination ensures you can produce high-quality designs that adhere well to fabrics.

How does DTF printing compare to other printing methods?

DTF printing stands out for its versatility across fabric types, including both light and dark materials. Compared to screen printing and heat transfer vinyl, DTF transfers offer superior vibrancy and durability, making them an excellent choice for detailed and customized designs.

What challenges might I face when using DTF transfers?

Common challenges in DTF printing include achieving precise calibration of your printer and heat press, which is crucial for quality prints and adhesion. Additionally, the initial investment for equipment can be higher than other methods, but long-term savings are often realized.

Are there resources available for beginners in DTF printing?

Yes, there is a wealth of resources for beginners in DTF printing, including online forums, social media groups, and comprehensive guides on websites like Printavo. These platforms offer tutorials, expert advice, and community support to help newcomers successfully navigate DTF transfers.

| Key Points | Description |

|---|---|

| Introduction to DTF Transfers | Explains the significance and growing popularity of DTF transfers in custom apparel printing. |

| How DTF Printing Works | Details the process of printing designs onto a special film which is then transferred to fabric using heat and pressure. |

| Equipment Needed | Core equipment includes a DTF printer, hot melt adhesive powders, transfer films, and a heat press machine. |

| Benefits | Vibrant colors, durability, and ease of use make DTF transfers increasingly popular. |

| Challenges | Calibration and initial costs are important considerations for beginners. |

| Recent Trends | Growing community support through forums, blogs, and tutorial resources for beginners. |

| Applications | DTF transfers are not just for apparel; they are also used in home decor and personalized gifts. |

| Conclusion | DTF transfers offer a revolutionary method for high-quality custom printing, accessible to all. |

Summary

DTF Transfers mark a new era in custom apparel production, offering unmatched versatility and quality in printing. With their vivid colors and durability, they cater to a wide range of creative applications, from clothing to home decor. As the demand for personalized items grows, understanding DTF transfers becomes a vital asset for both hobbyists and small businesses alike. As technology and community resources continue to evolve, the potential for innovative designs and applications will only expand, making DTF transfers an indispensable tool for creative expression.