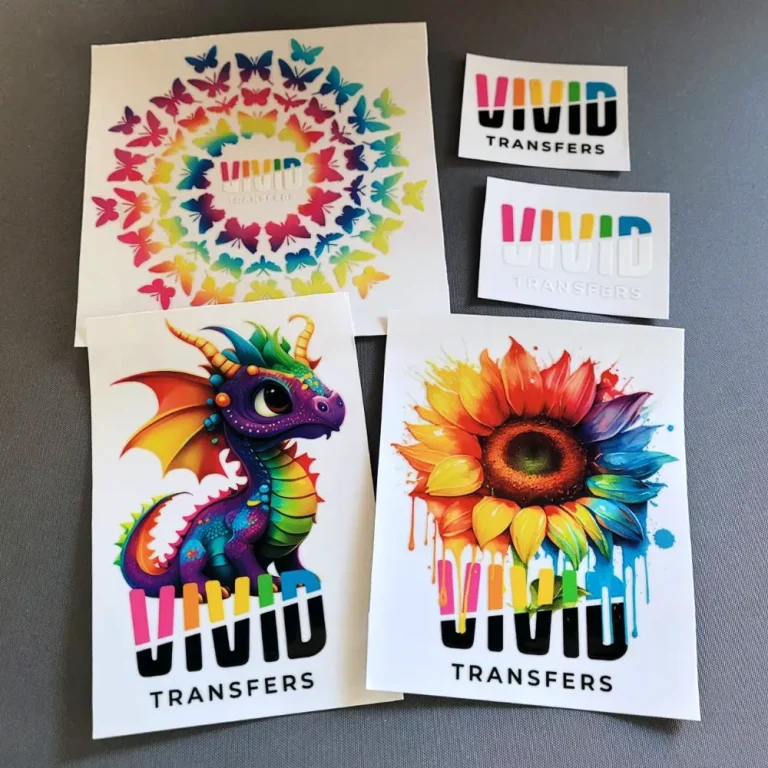

UV DTF transfers are revolutionizing the printing industry, combining the best aspects of UV printing and Direct to Film technology. This innovative technique allows for the production of vibrant, durable graphics that can be applied to a wide range of surfaces, including textiles and hard materials. The use of UV curing technology ensures that prints are not only visually striking but also highly resistant to wear and fading over time. In this guide, we will explore the essential steps involved in mastering UV DTF transfers, ensuring you have the right knowledge to elevate your custom apparel printing projects. As businesses and creatives alike embrace heat press transfers for their versatility and quality, understanding the intricacies of UV DTF will set you apart in a competitive market.

Exploring the realm of Direct to Film transfers, commonly referred to as DTF printing, reveals a cutting-edge approach to modern printing solutions. This process leverages the advantages of UV-based systems to create eye-catching designs that adhere effectively to both flexible and rigid substrates. The implementation of UV curing technology adds a layer of durability, making these prints suitable for various applications—from custom apparel to promotional goods. By utilizing advanced heat press transfers, users can achieve a superior finish, showcasing intricate artworks that stand the test of time. As you delve deeper into this printing technique, you’ll discover the diverse opportunities that await in the ever-evolving landscape of custom graphics.

Understanding UV DTF Transfers

UV DTF (Direct to Film) transfers are revolutionizing the way graphics are printed onto various materials. At its core, this method utilizes advanced UV printing technology, which allows inks to cure instantly under UV light, offering a sharp and vibrant finish. Unlike traditional printing techniques, UV DTF transfers can adhere to a wide variety of substrates such as textiles, plastics, and metals, making them highly versatile in various industries, from fashion to promotional products. This innovative approach merges creativity with durability, ensuring that designs not only look exceptional but also withstand the test of time.

Furthermore, understanding the intricacies of the UV DTF process is essential for achieving high-quality results. This includes recognizing the importance of selecting the right transfer films and UV-reactive inks that are compatible with your chosen substrates. A well-conceived understanding of UV curing technology aids in creating stunning prints that are resistant to fading and scratches. As demand for custom apparel printing continues to rise, incorporating UV DTF transfers can place businesses ahead of the competition, giving them a distinct edge in quality and design.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or Direct to Film transfers, utilize UV printing technology to create vibrant, durable graphics on various surfaces. The process involves printing designs onto a special film with UV-reactive inks, which are cured instantly under UV light, allowing for high-quality prints that bond well with materials like textiles and plastics.

What advantages do UV DTF transfers offer compared to traditional printing methods?

UV DTF transfers provide several advantages over traditional printing methods, including superior adhesion to diverse substrates, faster curing times due to UV curing technology, and the ability to produce intricate designs with high detail. The prints are also highly resistant to fading and scratching, making them ideal for custom apparel printing and promotional items.

How do I prepare materials for UV DTF transfers?

Preparing materials for UV DTF transfers involves selecting high-quality transfer films and UV inks that are compatible, ensuring your substrates are clean free of dust or oils. Proper surface preparation is crucial for achieving optimal adhesion and quality in your custom apparel printing tasks.

What is the curing process in UV DTF transfers?

The curing process in UV DTF transfers uses a UV light source to solidify the printed inks. This step is essential to ensure the durability of the prints. It’s important to monitor the distance of the light and the curing time closely, as improper curing can result in prints that fade or become brittle.

What role does heat pressing play in UV DTF transfers?

Heat pressing is a critical step in the UV DTF transfer process where the cured film is applied to the substrate with heat and pressure. This ensures proper adhesion of the print to the material. Adjustments in time and temperature settings are necessary based on the type of substrate being used.

How can I ensure the durability of my UV DTF transfers?

To ensure the durability of UV DTF transfers, conduct wash and wear tests on the finished products. Assess how well the prints withstand washing, abrasion, and UV exposure. This testing can help identify areas for improvement in both the printing process and material selection for long-lasting results.

| Key Point | Details |

|---|---|

| Overview of UV DTF Transfers | Combines UV printing and direct-to-film technology for high-quality, durable prints on various surfaces. |

| Key Steps to Master | Preparation, printing setup, curing, transfer application, durability testing. |

| Materials Needed | High-quality transfer films & UV-reactive inks, clean substrates. |

| Curing Process | Cure prints with UV light; monitor distance and timing for best results. |

| Transfer Application | Heat press printed film onto substrate; allow cooling before peeling. |

| Durability Testing | Test prints for washability, abrasion resistance, and UV exposure. |

| Recent Innovations & Trends | Ongoing equipment advancements and increasing market demand in custom products. |

Summary

UV DTF Transfers represent an exciting evolution in the printing industry, merging cutting-edge technology with creative possibilities. By understanding the intricacies involved—from material preparation to the printing, curing, and transfer processes—practitioners can achieve stunning results on a variety of surfaces. The recent innovations and growing market demand for high-quality prints further highlight the importance of mastering this technique. As you refine your skills in UV DTF Transfers, you unlock the potential for vibrant designs and robust products, paving the way for creative exploration and business growth in this dynamic field.