In the dynamic realm of custom apparel and merchandise, utilizing DTF transfers has emerged as a game-changer for getting vibrant designs on fabric. Direct-to-Film (DTF) printing offers an innovative approach, enabling designers to achieve intricate graphics with durability that stands the test of time. This method is popular not just for its impressive visual appeal, but also for its versatility across various materials, providing endless possibilities in fashion and design. In this blog, we will explore how optimizing DTF transfer applications, keeping in mind the DTF size guide, is crucial for delivering striking results that captivate consumers. Furthermore, by adhering to best practices for DTF, designers can ensure that their creative visions translate seamlessly onto textiles, enhancing overall garment aesthetics and wearability.

Exploring the world of fabric printing, one encounters the incredible benefits of Direct-to-Film transfers, often referred to as DTF printing. This method revolutionizes the way designs are manifested onto textiles, combining affordability with high-quality outcomes. By using specialized films, creators can achieve vivid colors and detailed prints, opening new avenues for personalization in clothing, accessories, and crafts. A comprehensive understanding of design scaling, common size options, and application techniques is essential for maximizing the effectiveness of these transfers. As we break down the various dimensions and design considerations associated with DTF transfers, we will uncover strategies to enhance both the visual appeal and durability of custom creations.

Understanding the DTF Size Guide

When it comes to Direct-to-Film (DTF) transfers, having a comprehensive understanding of the size guide is essential for ensuring the success of your designs. DTF sizing can significantly affect not only the visual appeal but also the durability of your apparel. The DTF size guide typically categorizes designs into small, medium, and large transfers, each suited for specific applications. For example, a small transfer measuring 8×10 inches is perfect for branding or smaller graphics on items like caps and backpacks. Conversely, larger transfers, such as 16×20 inches, are ideal for impactful designs like full-back prints on t-shirts, allowing the colors and details to shine.

The DTF size guide doesn’t merely dictate dimensions; it plays a pivotal role in the overall design strategy. Designers must take into account the fabric area and product type. For instance, when applying a medium-sized transfer of 11×17 inches to a garment, one must consider the placement to ensure optimal visibility without clogging key design features. Choosing the right size not only enhances the aesthetic but also improves customer satisfaction by delivering a professionally finished product that stands out.

Best Practices for DTF Transfers

To maximize the effectiveness of DTF transfers, adhering to best practices is crucial for both novice and experienced designers. Firstly, it’s essential to match the design size with the garment’s placement area. This consideration can significantly influence the visual harmony of the design. If a large transfer is misaligned on a small shirt, it can dominate the garment and detract from its overall appeal. Hence, a careful selection of size and design placement based on the fabric type can lead to successfully executed projects.

Additionally, maintaining the correct DPI for your artwork is pivotal in achieving high-quality prints. A resolution of at least 300 DPI ensures that all details are crisp and vibrant, particularly in larger designs where fine details become more prominent. It’s also recommended to test different transfer sizes on various fabrics to find what works best. By experimenting, you can discover unique aesthetics that can elevate your brand’s offerings.

Design Scaling Techniques for DTF

Design scaling is an integral aspect of using DTF transfers effectively. Proper scaling ensures that designs remain intact during the printing process, particularly when transitioning from digital files to physical transfers. For larger designs, while it’s possible to maintain high quality, scaling must be handled with care to avoid pixelation or loss of detail. To achieve this, designers should utilize vector graphics whenever possible, as these are resolution-independent and scale smoothly without loss of quality.

Moreover, plan your graphics with size variability in mind. The intricate details that make a design pop can be lost in smaller scales, so it’s essential to adapt graphics accordingly based on their intended size. Establishing a scaling template can help streamline the process for various garment sizes, ensuring your designs not only look good but also translate effectively across different products.

Importance of DTF Transfer Application

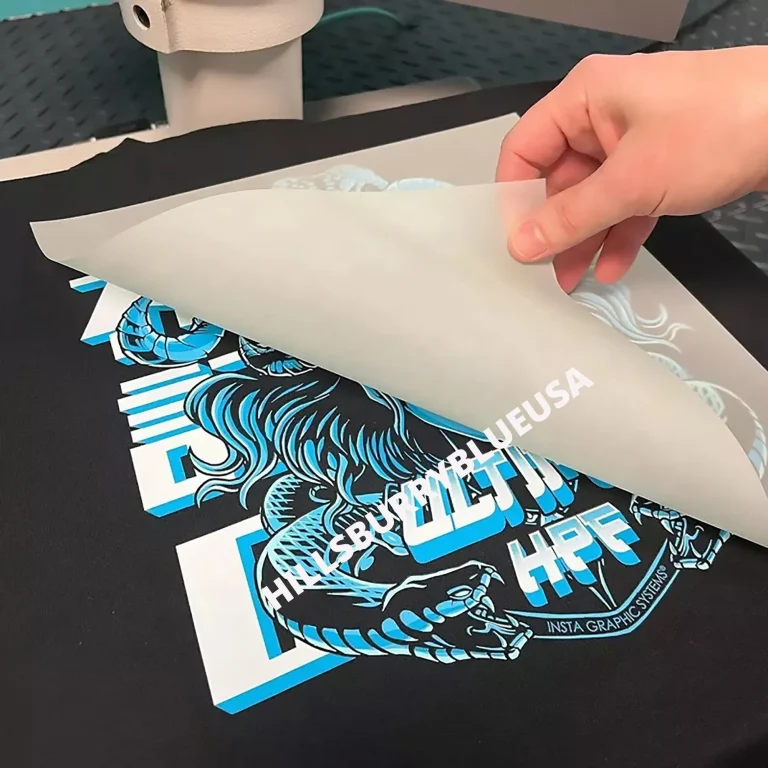

The application process for DTF transfers is critical in determining the final look and durability of your designs. Proper heating and pressing techniques play a significant role in ensuring the print adheres correctly to the fabric. For DTF application, using a heat press is preferred because it provides even temperature distribution and the right amount of pressure needed for the transfer to adhere effectively. It’s also important to follow manufacturer guidelines regarding temperature and pressure settings for the specific size of the transfer being applied.

An effective transfer application not only guarantees the longevity of the print but also enhances the wearability of the garment. A poorly applied transfer can lead to issues like peeling or cracking, thus undermining the quality of your work. To mitigate these risks, take the time to conduct thorough testing prior to mass production, ensuring that your DTF transfers maintain a professional finish and withstand the rigors of everyday wear.

Recent Innovations in DTF Technology

Advancements within the DTF transfer technology landscape have rapidly evolved, providing users with improved tools and techniques that elevate the quality of transfers. Recent innovations have introduced new types of transfer films that enhance color vibrancy and detail retention, even after numerous washes. These films are engineered to withstand fading and cracking, providing a longer-lasting solution for custom apparel designers seeking to deliver high-quality products.

Staying current with these technological advancements is essential for designers looking to maximize their craftsmanship. By utilizing the latest films and printers equipped with cutting-edge technology, you can achieve superior results in your DTF applications. This knowledge not only enhances the creative process but also helps ensure that your designs stand up to the demands of the competitive marketplace, attracting more customers seeking high-quality customized items.

Exploring DTF Transfer Market Trends

The DTF transfer market is witnessing significant trends that cater to the increasing demand for customized apparel. Consumers today are seeking unique designs that express individuality, leading to a rise in small businesses and independent designers adopting DTF printing technology. By understanding current market preferences and consumer behavior, designers can tailor their offerings to capitalize on these trends, offering products that resonate with audiences looking for personalized merchandise.

Furthermore, sustainability is becoming increasingly important to consumers, prompting designers to seek eco-friendly DTF solutions. Innovations in biodegradable films and inks are emerging, enabling brands to meet the growing demand for sustainable practices while maintaining the vibrant quality of DTF transfers. Those who embrace these trends will not only appeal to the environmentally-conscious consumer but also enhance their brand image in an industry that is increasingly prioritizing sustainability.

Frequently Asked Questions

What is the significance of the DTF size guide in Direct-to-Film printing?

The DTF size guide is crucial for Direct-to-Film printing as it helps designers select the appropriate transfer size for their designs. Choosing the right size ensures that intricate details are preserved and the print quality remains high. By following the DTF size guide, you can optimize the visual impact of your designs on various fabrics.

How does design scaling affect DTF transfer application?

Design scaling directly impacts DTF transfer application by determining how well the graphics will translate onto the fabric. Larger designs tend to maintain clarity and detail better than smaller ones during the printing process. Proper scaling ensures that the final product looks professional, enhancing the overall aesthetic of the garment.

What are some best practices for DTF transfers to ensure high-quality prints?

To achieve high-quality DTF transfers, adhere to best practices such as using high-resolution images (at least 300 DPI), accurately scaling your designs, and properly adjusting temperature and pressure during application. Additionally, experimenting with different sizes and films can lead to better results, ensuring your designs stand out.

What are the different common sizes available for DTF transfers?

Common sizes for DTF transfers include small (8×10 inches), medium (11×17 inches), and large (16×20 inches). Each size is suited for different types of applications, from logos on smaller items to full-back designs on t-shirts, allowing for versatility in custom apparel design.

How can understanding print quality improve DTF transfers?

Understanding print quality is key to optimizing DTF transfers because it influences the clarity and durability of the final design. High-resolution images and properly scaled designs contribute to better print quality, ensuring that colors remain vibrant and details are sharp even after repeated washing.

What recent developments have improved DTF transfer technology?

Recent developments in DTF transfer technology include advancements in transfer films that enhance color accuracy and durability. Newer films are designed to withstand multiple washes without fading, allowing businesses to produce high-quality, long-lasting prints that elevate the appeal of custom apparel.

| Key Considerations for DTF Transfers | Description |

|---|---|

| Design Scaling | Scaling designs appropriately ensures that quality is maintained, especially for intricate graphics. |

| Print Quality | High-resolution images (300 DPI) are essential, with larger transfers often delivering clearer detail. |

| Application Considerations | Proper pressure and temperature during application depend on the transfer size for better adhesion. |

| Common Size Options | Small (8×10 in), Medium (11×17 in), and Large (16×20 in) fulfill different design needs. |

| Recent Developments | Innovations in DTF technology improve color accuracy and durability of transfers. |

| Practical Tips | Match design size with placement to enhance presentation; experiment for best results. |

Summary

DTF transfers are crucial for enhancing apparel designs, allowing for vibrant graphics and detailed imagery. Understanding how the size of your transfer influences design quality, application methods, and the overall aesthetic outcome is vital for anyone looking to excel in custom printing. By mastering the dynamics of transfer sizes and implementing techniques discussed, you can maximize the impact of your designs and stay competitive in the custom apparel market.