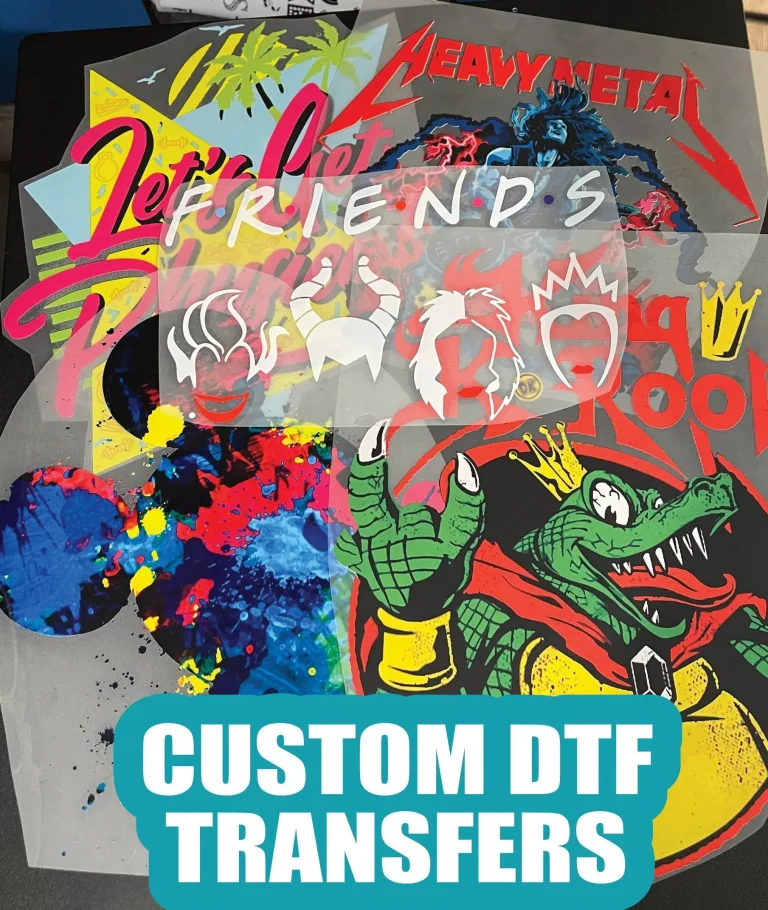

DTF transfers, or Direct-to-Film transfers, have emerged as a revolutionary technique in the garment printing world, enabling creators to easily transfer vibrant designs onto textiles. Ideal for both novices and seasoned professionals, DTF transfers allow for intricate patterns and vivid colors that enhance any fabric. This method has garnered significant attention for its efficiency and quality, making it essential for anyone interested in textile printing. In this guide, we will explore the best practices for DTF transfers, offering you insights that can help you avoid common mistakes while maximizing your creative potential. Understanding the ins and outs of DTF printing can set you on the path to producing stunning, long-lasting designs that speak to your artistic vision.

Also known as Direct-to-Film printing, this innovative method utilizes specialized films to transfer designs directly onto fabrics, making it a preferred choice for many textile enthusiasts. As the craft of fabric printing evolves, it’s crucial to grasp effective strategies that will enhance your DTF printing techniques. For beginners, understanding the nuances of film selection, ink quality, and the curing process can significantly influence the success of your projects. By implementing proven best practices for DTF transfers, you can ensure vibrant and durable prints. This article aims to provide valuable textile printing tips that will empower you in your journey of mastering this versatile printing method.

Understanding DTF Printing Techniques

Direct-to-Film (DTF) printing is a revolutionary method in textile printing that combines digital printing and heat transfer techniques to achieve high-quality results. It’s essential to differentiate DTF from other printing methods such as screen printing or direct-to-garment (DTG) printing, as each technique has its unique advantages and applications. DTF allows for a wide range of colors, patterns, and details to be printed directly onto a special film, which can then be transferred onto fabric using heat and pressure. This flexibility makes it an outstanding choice for custom apparel, including t-shirts, hoodies, and more.

Moreover, the DTF process ensures that designs are not only vibrant but also long-lasting. Unlike traditional methods, DTF printing utilizes specialized inks that bond exceptionally well with both the film and fabric. This results in prints that are resistant to cracking and fading, even after multiple washes. As beginners delve into DTF, understanding this printing technique is fundamental to mastering the craft and achieving professional-grade results.

Choosing the Right DTF Transfers

Choosing the right DTF transfers is crucial in determining the quality of your final product. Not all DTF transfers are created equal, and selecting the right film and adhesive can significantly impact adhesion and print detail. Look specifically for films that are compatible with the type of fabric being used. For instance, if you are printing on cotton, seek out films that are optimized for cotton textiles to ensure a strong bond.

Additionally, beginners should pay attention to the film’s finish, which can be matte or gloss. Matte finishes generally provide a more subdued look, while gloss can enhance vibrancy. The right choice may depend on the desired aesthetic of the final product. It’s also wise to consider the thickness of the film; thinner films can conform better to fabric contours, reducing the chance of peeling over time.

Essential Tips for DTF Printing Equipment Setup

Getting your equipment setup right is one of the most vital steps in successful DTF printing. Ensure your printer is specifically designed for DTF or compatible with DTF inks, as this will make a world of difference in application and print quality. Begin by addressing printer settings, including temperature, speed, and ink levels, to optimize for DTF transfers. A common mistake among beginners is neglecting to adjust these settings, which can result in poor print quality and wasted materials.

Furthermore, it’s critical to maintain your DTF printer regularly. Clean the printhead and nozzles often to avoid ink clogs, which can lead to streaky prints or color inaccuracies. Invest in quality cables and connections to ensure data transfer is smooth and uninterrupted. By setting your equipment properly, you lay a strong foundation for producing impressive DTF transfers.

Best Practices for Curing DTF Transfers

Curing is a key step in ensuring that DTF transfers adhere properly to the fabric. This process involves applying the right amount of heat and pressure for a specific duration, which activates the adhesive powder used in DTF transfers. Beginners must pay close attention to curing time and temperatures indicated by the adhesive manufacturer, as failing to adhere to these guidelines can result in poor adhesion and designs that don’t withstand wear.

To achieve the best results, consider investing in a heat press that can maintain consistent temperature and pressure. It’s also beneficial to conduct tests with different fabrics and adjust the curing settings accordingly. By refining your curing practice, you can create durable transfers that not only look good but also last longer, enhancing the overall quality of your products.

Conducting Test Prints: A Step-by-Step Guide

Before diving into mass production, conducting test prints is a significant step that can save time and resources. Test prints allow you to identify potential issues with adhesion, colors, and the overall aesthetic of your designs. Start with smaller prints and experiment with different fabrics to see how well the DTF transfers perform under various conditions.

Make it a habit to document your settings and observations during the test printing phase. This information will be invaluable as you fine-tune your process, ensuring that you achieve the highest quality outputs in subsequent runs. By investing time in this essential practice, beginners can significantly reduce errors and frustrations when moving into larger production.

Adapting to Common Challenges in DTF Transfers

While DTF printing offers remarkable advantages, beginners may still encounter common challenges such as adhesion issues, fading colors, and incomplete curing. Understanding these potential pitfalls will help you adapt and overcome them efficiently. For example, if you notice poor adhesion, check the curing process and the quality of the materials used. Sometimes, the resolution of the print may also affect overall adhesive performance, so ensuring everything aligns correctly is vital.

Additionally, keeping a log of any problems faced during your projects can lead to increased efficiency in your workflow. Regularly troubleshoot your systems, from the printer settings to material quality. As you gain more experience, these insights will allow you to refine your approach and be better prepared for future projects in DTF printing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a printing technique that allows designs to be printed onto a special film before being heat transferred onto fabric. This method uses a printer to apply DTF-specific inks onto the film, followed by a unique adhesive powder. Once cured with heat, the transfer can be applied to various textiles, ensuring vibrant and durable prints.

What are the best practices for DTF printing that beginners should follow?

For beginners in DTF printing, it’s essential to focus on several best practices. These include maintaining proper printer settings, selecting the right DTF film, using high-quality inks and adhesives, perfecting the curing process, and conducting test prints before larger runs. Following these guidelines will help achieve professional results and minimize common printing issues.

How do I ensure successful adhesion when using DTF transfers?

Successful adhesion in DTF transfers relies on several factors: the correct temperature and time during the curing process, using suitable DTF films with proper coatings, and employing high-quality adhesive powders. Always refer to the manufacturer’s instructions for optimal curing settings and conduct test prints to fine-tune your method.

What materials are recommended for DTF printing?

For effective DTF printing, it’s recommended to use DTF-specific inks known for their vibrancy and wash resistance. Additionally, choose adhesive powders formulated for DTF processes and high-quality transfer films with appropriate finishes and coatings. Investing in quality materials will significantly enhance your print results.

Are there specific temperature settings I should be aware of for DTF transfers?

Yes, different DTF printers have unique temperature requirements for optimal printing. Generally, DTF transfers need specific curing temperatures, often between 160°C to 180°C (320°F to 356°F). Always consult your printer’s manual to determine the correct settings that will ensure the best adhesion and durability of your prints.

What should I include in my testing process for DTF printing?

In your testing process for DTF printing, ensure you run test prints on the same fabric you plan to use for final products. Check for adhesion quality, color vibrancy, and any potential issues with the design. Analyzing these test prints will help refine your settings and processes for improved results in larger production runs.

| Best Practices | Key Points |

|---|---|

| 1. Maintain Proper Printer Settings | Familiarize with printer settings like temperature, speed, and quality to ensure color accuracy and adhesion. |

| 2. Choose the Right Film | Select films with matte or semi-gloss finishes suited for DTF and ensure they have the correct coating. |

| 3. Use Quality Inks and Adhesives | Invest in DTF-specific inks and compatible adhesive powders to enhance color vibrancy and durability. |

| 4. Correct Curing Process | Follow manufacturer guidelines for curing temperature and time to ensure strong adhesion. |

| 5. Test Prints | Conduct test prints on intended fabrics to catch issues and refine the printing process. |

Summary

DTF transfers are revolutionizing the garment printing industry, allowing both beginners and experts to create vibrant and durable designs. By adhering to five essential best practices—maintaining proper printer settings, selecting the right film, using quality inks and adhesives, perfecting the curing process, and conducting thorough test prints—newcomers can significantly enhance their overall results. Emphasizing these practices will not only minimize common mistakes but also foster the creation of professional-grade textile prints that stand the test of time. Investing time into mastering DTF transfers rewards printers with stunning results and a competitive edge in the market.