UV DTF transfers are quickly becoming a game-changer in the realm of custom artwork and printing technology. This cutting-edge method utilizes ultraviolet printing technology to achieve vivid colors and intricate designs on a variety of materials, ensuring that your artwork looks striking and professional. By leveraging the DTF transfer process, artists can create durable prints that maintain their vibrancy over time, catering to both personal and commercial needs. In this guide, we will explore essential design application tips, the extensive benefits of UV DTF transfers, and how to effectively use this innovative technique to bring your artwork to life. Join us as we dive deeper into the exciting opportunities that await you with UV DTF transfers.

Direct-to-film printing, often referred to as DTF, alongside its ultraviolet counterpart, offers a unique approach to artwork reproduction. This modern printing solution is perfect for producing high-quality custom transfers that can elevate any project. By employing advanced UV printing methods, artists and businesses can now explore new dimensions of creativity without sacrificing durability or vibrancy. Additionally, understanding the nuances of the design application process is crucial for maximizing the potential of your prints. Embrace the evolution of artwork printing through this powerful technique and discover the creative possibilities it unlocks.

Exploring the UV DTF Transfer Process

The UV DTF transfer process is a fascinating blend of cutting-edge technology and artistic expression. The initial step involves using high-quality UV-reactive inks that are specifically designed for this method. Once the design is printed onto the special film, the UV light rapidly cures the ink. This curing process not only enhances the vibrancy of the colors but also ensures that the printed design retains its integrity against fading and scratches, making it ideal for various applications.

Understanding the nuances of the UV DTF transfer process is critical for artists and business owners looking to fully utilize this technique. The inks used in UV DTF printing interact dynamically with the substrates, emphasizing the importance of selecting the right materials. By combining this innovative printing technology with high-resolution artwork, artists can achieve stunning results that stand out in a competitive market.

Artwork Preparation for Optimal Results

Before embarking on the UV DTF transfer journey, artwork preparation plays a pivotal role in the quality of the final product. It is essential to create designs using professional graphic design software, ensuring that every detail is crisp and vibrant. A resolution of 300 DPI or higher should be maintained to prevent any pixelation issues during the transfer process, which can compromise the visual integrity of the artwork.

In addition, artists should focus on elements like color balance and contrast in their designs. Bright and bold colors typically yield the best results when printed using the UV DTF method. By investing time in meticulous design preparation, artists can facilitate a smoother transfer process and ultimately enhance the overall quality of their projects.

Selecting the Right Materials and Equipment

Choosing the appropriate materials and equipment is crucial for successful UV DTF transfers. Investing in a high-quality UV DTF printer is fundamental, as it directly affects the print quality. Printers that can handle a wide range of substrates, including textiles and rigid materials, provide the versatility needed for diverse projects. Additionally, selecting the right type of DTF film ensures the inks adhere perfectly and transfer seamlessly.

Alongside the printer, the ink quality is equally important. Opt for UV-reactive inks that promise vibrant colors and durability. By carefully selecting both the printer and the film, artists and businesses can significantly improve the final output, leading to products that not only look stunning but also stand the test of time.

The Benefits of UV DTF Printing

UV DTF printing offers numerous benefits, making it an attractive option for artists and businesses worldwide. One of the primary advantages is its remarkable versatility. This technique can be employed on a variety of materials, from fabrics to ceramics, enabling a wide array of artistic endeavors ranging from apparel design to promotional items.

Moreover, the durability of UV DTF transfers sets it apart from traditional printing methods. Prints produced through this process are less likely to scratch, fade, or wash out over time, providing long-lasting quality to the end users. This durability factor not only enhances customer satisfaction but also opens the door for a wider range of applications and products.

Real-world Applications of UV DTF Transfers

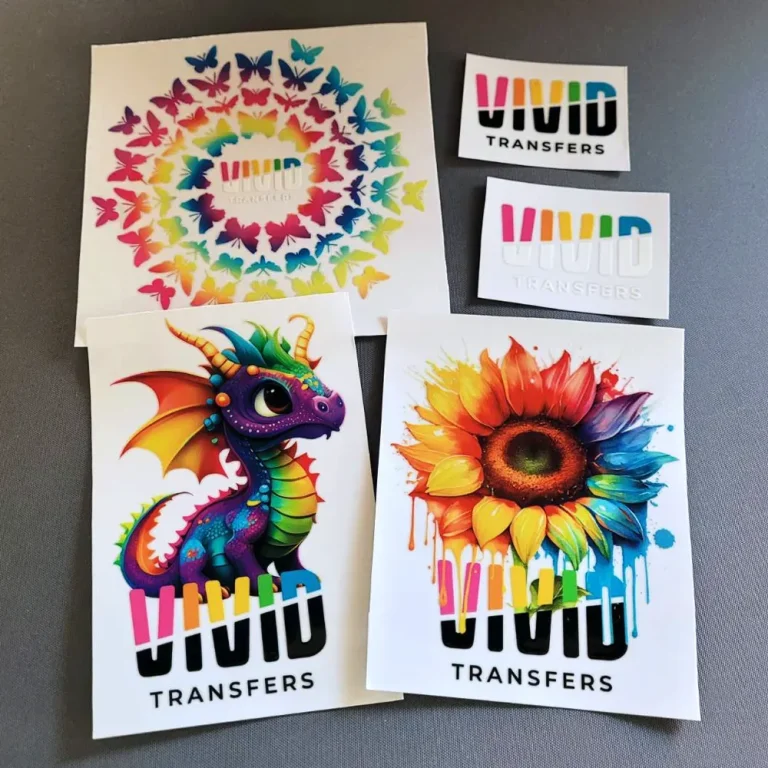

The applications of UV DTF transfers are diverse, catering to a multitude of industries and creative fields. Artists frequently utilize this technology to create custom apparel, such as T-shirts and hats, offering clients personalized options that stand out. Beyond fashion, businesses employ UV DTF for promotional products, crafting eye-catching banners, decals, and branded merchandise that enhance their marketing strategies.

Furthermore, the home decor market has witnessed an uptick in custom UV DTF prints, with artists creating unique wall art, pillows, and home accessories. This flexibility in application demonstrates the vast potential of UV DTF printing, encouraging creatives to explore innovative avenues for their artwork and expand their offerings.

Tips for Perfecting Your UV DTF Transfer Technique

To excel in UV DTF printing, it’s essential to embrace a few key practices that ensure the highest quality results. Always conduct test prints on the actual substrate you plan to use; this allows you to fine-tune your printer settings and ensure compatibility before commencing with larger orders. This precaution not only saves time but also prevents material waste.

Investing in quality materials is paramount for achieving success with UV DTF transfers. From inks to films, top-notch supplies contribute significantly to the vibrancy and durability of your final products. Additionally, staying updated with emerging trends in UV printing technology will help you refine your skills and keep your offerings relevant in the swiftly changing print market.

Frequently Asked Questions

What are UV DTF transfers and how do they work?

UV DTF transfers, or Ultraviolet Direct to Film transfers, utilize specialized inks that are printed on a film and cured with UV light, allowing vibrant designs to be transferred onto various materials. This technology is ideal for achieving high-quality artwork printing with long-lasting durability.

What materials can I use for UV DTF transfers?

UV DTF transfers can be applied to a wide range of substrates including textiles, ceramics, plastics, and more. This versatility makes UV DTF a popular choice for custom transfers across different products like apparel and promotional items.

How should I prepare my artwork for UV DTF printing?

To maximize your artwork with UV DTF transfers, ensure your design is high resolution (300 DPI) and save it in a suitable format like PNG or TIFF. Using graphic design software like Adobe Illustrator will also help in achieving optimal design quality.

What are some essential tips for the DTF transfer process?

Focus on color contrasts when designing, use specialized DTF films, and conduct test prints to fine-tune printer settings. It’s also crucial to understand the UV curing process as it secures the color and quality of your print.

Why choose UV DTF printing over traditional methods?

UV DTF printing offers several advantages including enhanced color vibrancy, increased durability against scratches and fading, and the ability to print on a wider variety of materials compared to traditional transfer methods.

Can UV DTF transfers be used for both small and large production runs?

Yes, UV DTF transfers are suitable for both small and large production runs. The efficiency of the UV curing process allows for quick handling and application, making it ideal for businesses looking to produce high-quality custom transfers at scale.

| Key Points | Details |

|---|---|

| What are UV DTF Transfers? | Printing images onto film using UV-reactive inks that cure instantly with UV light, enabling vibrant designs on various substrates. |

| Importance of Artwork Preparation | Using high-quality graphic design software and maintaining high resolution is crucial for quality prints. |

| Step 1: Design Preparation | Select reliable graphic software and export designs in PNG or TIFF for best quality. |

| Step 2: Printing the Design | Choose a high-quality UV DTF printer and specialized film for optimal results, adjusting printer settings accordingly. |

| Step 3: UV Curing Process | Curing with UV light ensures ink durability and prevents smudging; monitor exposure for quality. |

| Step 4: Transfer Your Design | Clean the surface for better adhesion and choose application methods based on the substrate. |

| Step 5: Quality Control | Inspect the transfer and maintain your printer for consistent quality results. |

| Advantages of UV DTF Transfers | Versatility, durability, and enhanced color vibrancy make UV DTF transfers a superior choice. |

| Applications of UV DTF Transfers | Suitable for apparel, promotional products, and personalized home decor. |

| Practical Tips for Success | Always test prints, invest in quality materials, and stay updated with market trends for best outcomes. |

Summary

UV DTF transfers revolutionize custom artwork by allowing artists and businesses to unlock vibrant, durable designs suitable for numerous materials. This innovative technique not only emphasizes artistic integrity but also ensures long-lasting quality. With meticulous preparation and a comprehensive understanding of the process detailed in this guide, creators can elevate their work, leading to eye-catching prints that are built to last. Embracing UV DTF transfers opens new avenues for creativity and product offerings, catering to a diverse audience ranging from clothing to unique promotional merchandise. Unlock your artistic potential by delving into the intricate methods of UV DTF transfers, and enhance your product line today.