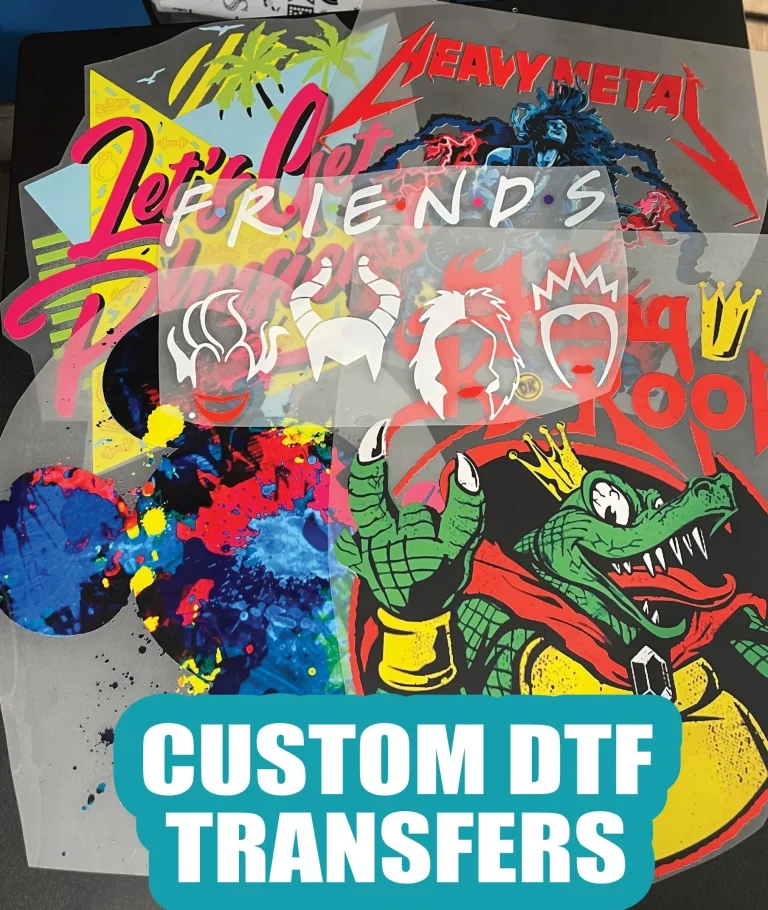

DTF transfers, or Direct to Film transfers, have revolutionized the custom printing industry by allowing vibrant, complex designs to be applied effortlessly onto various garments. Understanding the nuances of DTF transfer sizing is crucial for achieving stunning aesthetics and functional integrity in your printed products. In this article, we will explore essential best practices for sizing DTF transfers, ensuring that your designs not only fit perfectly but also stand out visually. From managing resolution to considering fabric types, mastering these DTF printing tips will elevate the quality of your finished pieces. Join us as we uncover how to size DTF transfers effectively and optimize your printing projects.

When discussing DTF transfers, also known as Direct Film transfers, one cannot overlook the critical importance of sizing in the printing process. The effectiveness of this innovative printing method, which enables intricate designs to be seamlessly transferred onto textiles, hinges on optimal sizing strategies. It is essential to grasp the best practices for DTF, including techniques for determining appropriate print areas and understanding the impact of fabric variety on transfer size. By adopting a comprehensive approach to sizing DTF transfers, you can enhance the quality and visual appeal of your custom apparel. Let’s delve deeper into the considerations that will set your DTF projects apart from the rest.

Essential Tips for DTF Transfer Sizing

When it comes to mastering DTF transfer sizing, one of the first crucial tips is to ensure that you are familiar with the dimensions of the garment onto which you will be transferring. Always measure the desired print area before finalizing your design. Aiming for a standard width of between 8 to 14 inches is often advisable for adult-sized apparel. This foundational step prevents common pitfalls such as awkward designs or misalignment on the garment.

Additionally, keep in mind that understanding your audience’s preferences is key. Certain designs may look appealing in larger sizes for fashion-forward audiences, while others may favor a more subtle approach. Tailoring the transfer size based on trends and customer feedback will not only enhance the aesthetics of the print but also ensure customer satisfaction.

Best Practices for DTF Printing

Best practices for DTF printing extend beyond just sizing; they encompass the entire design process. A significant aspect involves utilizing high-resolution images, ideally at 300 DPI. This ensures that your final product not only looks vibrant but also retains clarity after being transferred to the garment. A rule of thumb is to test various resolutions to understand how they correlate with print sizes, allowing for a more polished outcome.

Moreover, maintaining the correct aspect ratio during the resizing process is critical. Failure to achieve this may lead to distorted images, compromising the professional look that custom apparel strives to provide. Using design software can assist in setting proper dimensions and keeping track of image integrity throughout the design journey.

The Importance of Measuring Garments

Accurate measurement of garments plays a pivotal role in achieving successful DTF transfers. By taking precise measurements of the printable area, you can tailor your designs to fit seamlessly on the intended fabric. This ensures your design doesn’t overwhelm or underwhelm the visual space of the product, optimizing its aesthetic appeal.

In addition, it’s essential to factor in the margins during the design phase. Leaving a margin of about 1-2 inches around your transfer will prevent any unwanted cropping during the heat pressing process. This attention to detail can greatly enhance the overall finish of your apparel, setting apart your prints from competitors.

Testing Your DTF Transfers Before Finalization

One of the best strategies in ensuring quality DTF transfers is to conduct testing through sample prints. By printing test samples, you gain valuable insights into how the selected size interacts with the fabric. This allows for adjustments that can improve the visual impact and overall success of the final product.

Moreover, creating a feedback loop is essential after these test prints. Share them with colleagues or your target audience to gather opinions on sizing, clarity, and overall aesthetics. This collaborative critique can uncover hidden issues that you might have missed and allows you to tweak your designs accordingly.

Leveraging Digital Mock-ups for Effective Design

Utilizing digital mock-ups is a game-changer in the design process for DTF transfers. These mock-ups provide a lifelike representation of how the design will look when applied to the garment, giving you the ability to test various sizes and positions without incurring production costs. By visualizing different layouts digitally, you can ensure that your sizing is both functional and visually appealing.

Furthermore, mock-ups can mitigate the risks associated with miscalculations in sizing. By experimenting with various aspects of your design, such as placement and scale, you can perfect your layout before investing in actual garment production, saving you time and resources in the long run.

Adapting to Different Fabric Types and Their Challenges

Considering the type of fabric you’ll be working with is crucial when sizing your DTF transfers. Each fabric has unique properties such as stretch, weight, and texture, which can influence how a design should be sized and positioned. For example, stretchy materials may call for smaller sizing to account for fabric movement and prevent distortion.

Equally important is understanding how different fabrics absorb ink and respond to heat during the transfer process. This knowledge will guide you in adjusting transfer size and print technique accordingly, resulting in a final product that not only looks great but lasts longer through wear and washing.

Frequently Asked Questions

What are the best practices for sizing DTF transfers effectively?

To size DTF transfers effectively, start by measuring the intended print area of the garment to ensure a good fit. Use high-resolution images (300 DPI) to maintain clarity and keep the aspect ratio consistent to avoid distortion. Leave 1-2 inches of margin around the design to ensure nothing important gets cut off during the transfer process.

How do I know the right dimensions for DTF transfer sizing?

For accurate DTF transfer sizing, measure the area of the garment where the transfer will be applied, typically between 8 to 14 inches wide for adult apparel. Utilize design software to set the canvas size accordingly and ensure that your design remains proportional and visually appealing.

What tips can improve my DTF printing results when sizing transfers?

To improve DTF printing results, conduct test prints to evaluate sizing and visual impact. Gather feedback from peers after showing mock-ups. Always start with high-quality transfer materials designed for DTF printing and consider the fabric type’s properties to adjust sizing appropriately.

Why is the resolution important in DTF transfer sizing?

High resolution is crucial in DTF transfer sizing because it affects the sharpness and clarity of the final print. Always use images at 300 DPI or higher to ensure your designs translate well onto the film and maintain quality after applying to the garment.

How do mock-ups help in determining the size of DTF transfers?

Mock-ups provide a visual representation of how your design will look on the garment, allowing you to experiment with different sizes and placements before actual production. This helps ensure your DTF transfer is correctly sized and meets both aesthetic standards and customer expectations.

What should I consider about the fabric type when sizing DTF transfers?

When sizing DTF transfers, consider the fabric type because different materials may stretch or shrink differently. For elastic fabrics, smaller and more flexible designs may be needed to accommodate movement and prevent distortion, ensuring your transfer looks great regardless of the garment’s stretch.

| Key Element | Best Practice | Importance |

|---|---|---|

| Understanding DTF Printing | Ensure you know how DTF printing works. | Helps in visualizing the process. |

| Resolution Matters | Use high-resolution images (300 DPI). | Ensures sharp and clear prints. |

| Maintaining Aspect Ratios | Keep the design proportions intact. | Prevents distortion and professionalism. |

| Measure the Garment | Measure print area before designing. | Ensures proper fit and appeal. |

| Allow for Margins | Leave a margin around the design. | Prevents cutting off important parts. |

| Scaling and Testing | Run test prints before finalizing. | Visualizes design and size adjustments. |

| Usage of Mock-ups | Use digital mock-ups to preview designs. | Allows experimentation with sizes. |

| Quality of Transfers | Select high-quality transfer materials. | Enhances adhesion and finish. |

| Consider the Fabric Type | Tailor sizing strategies to fabric types. | Ensures optimal results and flexibility. |

| Stay Updated with Developments | Engage with educational resources. | Enhances user experience and results. |

Summary

DTF Transfers are pivotal in delivering high-quality prints, and mastering their sizing is essential for success. By focusing on critical factors such as resolution, aspect ratios, garment measurements, and quality materials, users can ensure their designs not only look great but also maintain their integrity across different fabrics. Continuous learning through workshops and engaging with expert advice further enhances the DTF printing experience, leading to impressive results that stand out in the custom apparel market.