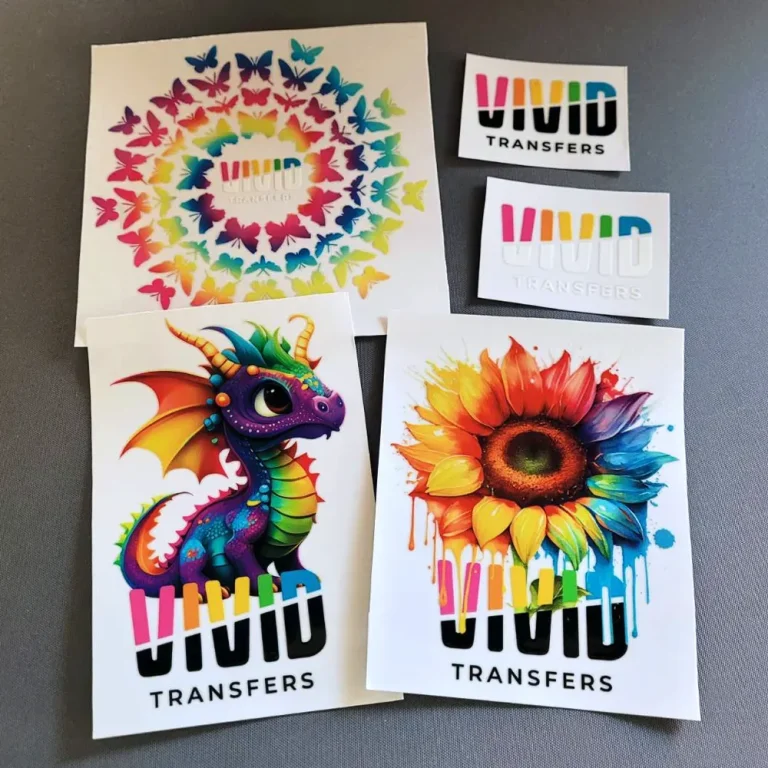

UV DTF transfers are quickly becoming a go-to method in the world of custom printing techniques. Merging the benefits of UV printing with Direct-to-Film printing, this innovative technology allows creators to achieve vibrant transfers that stand out in any marketplace. Whether you’re an artist, craftsman, or small business owner, mastering UV DTF can elevate your designs with stunning clarity and color. This beginner-friendly method provides the opportunity to explore various materials, from textiles to ceramics, making it a versatile choice in your printing arsenal. The increasing accessibility and demand for unique, personalized products only enhance the appeal of adopting UV DTF transfers for your creative projects.

When discussing the revolutionary technique of UV DTF printing, it’s essential to recognize its significance in the custom design landscape. Often referred to as Direct-to-Film printing, this approach utilizes cutting-edge UV printing technologies to create eye-catching and durable designs. Artists and entrepreneurs are drawn to this beginner printing method due to its ability to deliver detailed and vibrant images on a variety of surfaces. The combination of high-quality visuals and lasting performance positions UV DTF as a sought-after solution for anyone looking to personalize their products. As demand for customized transfers grows, understanding the ins and outs of this technique can set you apart in a competitive market.

Understanding UV DTF Transfers

UV DTF (Direct-to-Film) transfers represent a significant leap in the custom printing world, blending advanced UV printing technology with traditional transfer methods. This technique allows you to create vibrant images that are not only visually appealing but also durable, making them suitable for a variety of materials. Whether you’re a crafter looking to personalize items or a business owner aiming to expand product offerings, UV DTF transfers provide an innovative solution that elevates your creations.

The initial appeal of UV DTF transfers lies in their ability to produce striking colors and intricate designs. Unlike conventional printing methods, UV printing works by curing inks instantly under UV light, resulting in images that are both bold and long-lasting. This process not only enhances the print quality but also ensures that your designs remain intact through wear and washing, appealing to consumers who prioritize durability in their purchases.

Benefits of Using UV DTF Transfers

There are several standout features that make UV DTF transfers highly beneficial for both beginners and experienced printers. One of the most notable advantages is the print quality. The details captured in UV prints are nothing short of exceptional, allowing for complex designs that stand out. This level of quality is crucial for anyone looking to make an impression in the competitive world of custom printing.

Durability is another major selling point. UV DTF transfers are designed to withstand the rigors of everyday use, resisting both scratching and fading much more effectively than traditional prints. This resilience makes them particularly ideal for apparel and products that are frequently worn or used, ensuring that your customers remain satisfied with their purchases long after the initial sale.

Beginner’s Guide to UV DTF Printing

Starting with UV DTF printing might seem daunting at first, but with the right guidance, anyone can master this transformative technique. It begins with understanding the process: printing an image on specialized transfer film using UV-LED ink, followed by the application on the desired surface using a heat press. This straightforward sequence empowers beginners to achieve professional-quality results with practice.

To ease into UV DTF printing, it’s beneficial to start with simpler designs and smaller batches. This approach allows you to build confidence while gaining familiarity with the equipment and materials. As you grow in skill, gradually experiment with more intricate designs and a wider range of substrates, which will expand your creative repertoire.

Essential Equipment for UV DTF Transfers

To embark on your UV DTF printing journey successfully, having the right equipment is crucial. The centerpiece of your setup will undoubtedly be a quality UV printer. This device is specifically designed to deliver high-resolution prints and uses advanced technology to ensure that the ink cures seamlessly. Selecting a reliable printer will enhance your overall output quality and minimize operational hiccups.

In addition to the printer, you’ll need specific UV DTF transfer films that have been engineered for optimal ink adhesion and vibrancy. Pairing these films with a sturdy heat press or transfer machine ensures that your prints are applied smoothly and effectively. Investing in high-quality tools is essential for achieving lasting results and maintaining the integrity of your designs.

The Process of UV DTF Printing

Understanding the UV DTF printing process is essential, particularly for beginners keen to perfect their craft. The first step is the printing phase, where the image is printed onto the specialized transfer film utilizing UV-LED inks. The instant curing under UV light helps preserve the color vibrancy and detail, which is one of the hallmarks of UV printing.

Following printing, the next step is the actual transfer of the image onto the desired substrate. This requires careful management of heat and pressure, often facilitated by a heat press. The final phase includes post-curing, which solidifies the adherence of the image to the surface, resulting in a durable graphic that withstands daily use, making the overall process a success.

Current Trends in UV DTF Printing

The UV DTF printing technique is gaining momentum due to technological advancements and a surge in demand for custom-made products. One of the prevailing trends includes the growing accessibility of UV printers, which have become more advanced and affordable over recent years. This evolution opens up opportunities for small businesses and individual crafters to create professional-quality products.

Moreover, the consumer preference for personalized items has skyrocketed. With e-commerce flourishing, businesses leveraging UV DTF transfers can cater to a market increasingly focused on unique, tailored experiences. This makes UV DTF not just a printing method but a tool for artistic expression that resonates with modern consumers.

Frequently Asked Questions

What are UV DTF Transfers and how do they work?

UV DTF Transfers, or UV Direct-to-Film transfers, are a modern custom printing technique that uses UV printing technology to create vibrant images on transfer films. The process involves printing your design onto a specialized film using UV-LED ink, which cures instantly under UV light. This ensures high-quality, durable, and detailed outputs for various materials.

What equipment do I need to start using UV DTF Transfers?

To successfully utilize UV DTF Transfers, you will need essential equipment including a UV printer, specialized transfer films designed for DTF applications, and a heat press or transfer machine. This combination allows you to produce vibrant transfers with lasting quality.

How do UV DTF Transfers compare to traditional printing techniques?

UV DTF Transfers stand out due to their superior print quality, vibrant colors, and durability compared to traditional printing techniques. While conventional methods can fade and scratch easily, UV DTF techniques provide long-lasting, detailed prints that adhere well to various surfaces.

Can I use UV DTF Transfers on different types of materials?

Yes! One of the key benefits of UV DTF Transfers is their versatility. This printing method can be applied to a wide range of materials including textiles, ceramics, metals, and hard plastics, making it suitable for diverse projects in custom printing.

What are the advantages of using UV DTF Transfers for beginners?

For beginners, UV DTF Transfers offer several advantages: they produce vibrant images with intricate details, are durable against wear and fading, and are versatile across different surfaces. This makes it an accessible entry point into custom printing techniques.

What tips do you have for someone just starting with UV DTF Transfers?

Start with simple designs and small batches to build confidence. Experiment with print settings to achieve the best results for your materials, and invest in high-quality inks and transfer films to enhance the final product quality of your UV DTF Transfers.

| Key Feature | Description |

|---|---|

| Print Quality | Produces bright, vivid colors with high detail. |

| Durability | Resistant to scratching and fading, ideal for various applications. |

| Versatility | Can be applied to textiles, ceramics, and hard plastics. |

| Process | Involves printing, transferring, and post-curing for quality. |

| Equipment Needed | UV printer, specialized transfer films, heat press. |

| Beginner Tips | Start small, experiment with settings, use quality materials. |

| Current Trends | Advancements making printers accessible; demand for customization. |

Summary

UV DTF Transfers represent a cutting-edge technique that caters to both artists and small business owners by providing vibrant, durable, and versatile printing solutions. This modern method not only enhances print quality but also offers a unique opportunity for creative expression across various materials. As the trend continues to grow, embracing UV DTF transfers can significantly bolster your printing projects, allowing you to explore new creative horizons and meet the increasing demand for customization in today’s market.