DTF transfers, or Direct-to-Film transfers, are revolutionizing the realm of garment decoration by providing high-quality, custom designs that cater to diverse fashion trends. This innovative printing technology allows for intricate and vibrant artwork to be seamlessly applied to various fabrics, enabling brands to create personalized apparel that resonates with consumers. As the demand for unique, tailored designs grows, understanding the significance of transfer sizing becomes increasingly important, influencing the overall effectiveness of this cutting-edge method. In this fast-paced industry, utilizing DTF transfers can give businesses a competitive edge by enabling them to deliver exceptional products swiftly and efficiently. Dive into the world of DTF transfers and discover how mastering size can elevate your design game to new heights.

Direct-to-Film transfers have become a vital tool in the customization of clothing, utilizing advanced techniques that exceed traditional garment printing methods. Often referred to as DTF printing, this method emphasizes the importance of strategic design placement and sizing to enhance visual appeal and durability. The flexibility offered by this printing technology allows brands to explore innovative avenues for personalized designs, appealing to a broad spectrum of consumer preferences. As we examine this topic, consider how DTF printing can redefine the way businesses approach garment decoration and customization, promoting a fresh wave of creative expression in the apparel market. Understanding various aspects of transfer sizing and its integration into printing processes ensures that brands stay ahead in the competitive landscape.

Understanding DTF Transfers in Garment Decoration

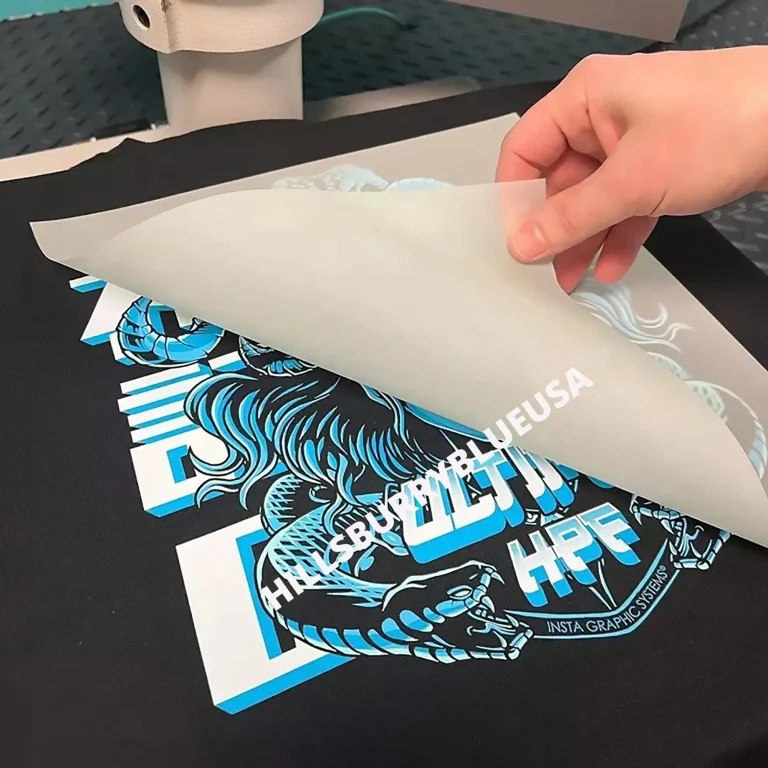

Direct-to-Film (DTF) transfers have revolutionized garment decoration by allowing intricate details and vibrant colors to be printed directly onto specially coated films. This process, utilizing advanced printing technology, creates a clear and durable transfer that can be applied to various garment types. DTF transfers provide a flexible option for customization, catering to both small runs and large batches, making them a preferred choice among apparel businesses looking to offer unique designs.

As companies compete in the dynamic world of personalized apparel, the adoption of DTF transfers allows them to stand out with high-quality prints that maintain their integrity and color vibrancy. Unlike traditional methods, DTF transfers enable designers to unleash their creativity, producing gorgeous garments that appeal to consumers demanding individuality in their clothing choices.

The Role of Size in DTF Transfers

When creating custom designs with DTF transfers, the sizing of the image is crucial. The right transfer size not only affects the final appearance but also ensures the quality of the print remains intact. If a design is too large, fine details may become blurred or lost during the transfer process, while smaller designs might not achieve the visibility required to catch a customer’s eye. Therefore, carefully evaluating transfer sizing is imperative to delivering an appealing product.

Moreover, proper sizing contributes to the adhesion and durability of the transfer on the garment. Each fabric type requires specific pressure and heat for the transfer to bond effectively. When sizes are inconsistent, it can lead to issues such as peeling or fading of the print, impacting the quality of the custom apparel being produced.

Efficiency in Ink Usage with Custom Sizes

Custom sizes in DTF transfers not only ensure a better fit and appearance but also play a pivotal role in ink efficiency. Larger transfers require more ink, which can drive up production costs and waste resources over time. By optimizing sizes to suit both the design aesthetic and efficiency of ink usage, apparel companies can significantly reduce their operational expenses.

This efficient use of resources means that businesses can maximize their production capabilities without compromising on quality. Crafting custom designs that take into account both the right size and adequate ink usage streamlines the overall process, ultimately benefiting the company’s bottom line.

Emerging Trends in DTF Transfers

The landscape of DTF transfers is constantly evolving, with new trends emerging as the technology matures. A notable shift is towards eco-friendly innovations, with many businesses looking to adopt sustainable practices within their manufacturing processes. This includes utilizing biodegradable inks and recyclable film materials to appeal to the environmentally-conscious consumer.

Additionally, the integration of AI within design processes enhances efficiency and customization capabilities. Businesses can harness intelligent software to analyze consumer preferences, allowing for adaptive sizing adjustments that can better meet customer expectations for personalized apparel. These advancements signal a promising future for DTF transfer technology.

Consumer Demand for Customization in Apparel

As the market moves towards customized apparel, consumer expectations have shifted. Personalization is no longer a luxury; it’s quickly becoming a standard demand. Customers now look for options that extend beyond basic designs, a trend that DTF transfers can readily fulfill by providing tailor-made solutions for varying size preferences.

This demand for unique, personal designs paired with the versatility of DTF transfers allows brands to cater to a diverse clientele. Businesses that embrace customization have a unique opportunity to build strong relationships with their customers, fostering loyalty and driving repeat sales as they meet individual preferences systematically.

The Future of DTF Transfers and Custom Design Innovation

Looking ahead, the future of DTF transfers promises even greater innovations that will continue to enhance the garment decoration industry. Technological advancements are expected to bring forth machines capable of even more complex designs, integrating multiple materials and layers within a single transfer. This capability could expand the horizons for customized apparel even further.

Moreover, with the trend towards sustainable practices gaining momentum, businesses that invest in environmentally responsible production methods, particularly in DTF transfers, stand to gain significant customer trust and loyalty. The intersection of customization, technology, and sustainability will likely define the next chapter of garment decoration.

Frequently Asked Questions

What are DTF transfers and how do they work in garment decoration?

DTF transfers, or Direct-to-Film transfers, are a printing technology used in garment decoration. They involve printing designs onto a special film that can be heat-applied to various fabrics. This method allows for intricate, colorful designs that cater to customization needs in personalized apparel.

Why should businesses use DTF transfers for custom designs?

Businesses should choose DTF transfers for custom designs due to their versatility with different garment types and their ability to produce high-quality outputs. This printing technology offers vibrant colors and precise details, making it an optimal choice for creating standout personalized apparel.

How does transfer sizing impact DTF printing quality?

Transfer sizing in DTF printing significantly impacts design quality. A correctly sized transfer ensures that designs maintain their integrity, avoiding distortion or loss of detail. Proper sizing plays a critical role in achieving the desired visual effect and enhances the overall appeal of the garment.

What are the durability benefits of properly sized DTF transfers?

Properly sized DTF transfers enhance adhesion and durability. When the size of a transfer is appropriate for the fabric, it ensures the ink bonds well during the application process, which reduces the likelihood of peeling or fading and ultimately extends the lifespan of the design on the garment.

How can customizing transfer sizes save costs in DTF printing?

Customizing transfer sizes can save costs in DTF printing by optimizing ink usage. Larger transfers consume more ink, which can increase production costs. By adjusting sizes carefully, businesses can maintain quality while managing resources effectively, improving overall efficiency and profitability.

What future trends should businesses consider in DTF transfer technology?

Businesses should be aware of future trends in DTF transfer technology such as eco-friendly innovations, automated design processes involving AI, and expanded customization options. These advancements will help companies meet consumer demand for personalized apparel and maintain a competitive edge in the garment decoration industry.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | Printing designs onto a special film using advanced technology, which are then heat applied onto garments, offering intricate details and vibrant colors. |

| Versatility for Different Garments | Adaptable to various fabrics like cotton and polyester, allowing for experimentation with design sizes and placements. |

| High-Quality Output | Provides high-quality images with vibrant colors and precise details, essential for standing out in a competitive market. |

| Impact on Design Quality | The proper size enhances the design’s appearance on garments, avoiding distortion or visibility issues. |

| Adhesion and Durability | Proper sizing ensures good adhesion to the fabric, preventing peeling or fading of transfers. |

| Ink Efficiency | Larger transfers use more ink, affecting production costs; managing sizes can improve resource use. |

| Meeting Consumer Preferences | Customization has become an expectation; DTF allows tailoring designs to individual sizing needs. |

| Current Trends | Innovations like eco-friendly materials, AI integration for design sizing, and enhanced customization options are emerging. |

Summary

DTF transfers are revolutionizing the garment decoration industry by enabling high-quality, customized designs tailored to consumer preferences. The importance of sizing in DTF transfers cannot be understated, as it directly affects the overall design quality, durability, ink usage, and customer satisfaction. Businesses that capitalize on the advantages of DTF technology and pay attention to the specifics of sizing can stay competitive while meeting the growing demand for personalized apparel. As trends develop, embracing innovations and understanding the intricacies of DTF transfers will position brands for success in a rapidly evolving market.