In the vibrant world of custom apparel and merchandise printing, DTF Transfers have emerged as a game-changer for businesses and hobbyists alike. Short for Direct-to-Film printing, this innovative technique allows for high-quality, detailed designs to be seamlessly transferred onto various fabrics. Bursting with benefits, DTF printing offers unmatched versatility and superior vibrancy, making it a go-to choice for those eager to stand out in the competitive market of custom apparel printing. As trends in DTF transfer techniques evolve, the increasing accessibility of this technology promises to unlock new possibilities, empowering both small businesses and creative individuals. Join us as we delve into the comprehensive advantages, applications, and the latest trends surrounding DTF printing and discover how it can elevate your projects.

Revolutionizing the landscape of textile printing, Direct-to-Film transfer methods have captivated the attention of those involved in custom garment creation. Often referred to as DTF printing, this process entails printing designs onto special film before transferring them to a wide range of fabrics through heat and pressure. This modern printing solution not only enhances the quality of custom apparel but also accommodates intricate designs that traditional methods struggle to replicate. With numerous advantages such as cost-effectiveness and ease of use, it has quickly become a favored approach for custom apparel printing. Explore the dynamic realm of DTF techniques that are shaping the future of printing and embracing the rising trends in this exciting industry.

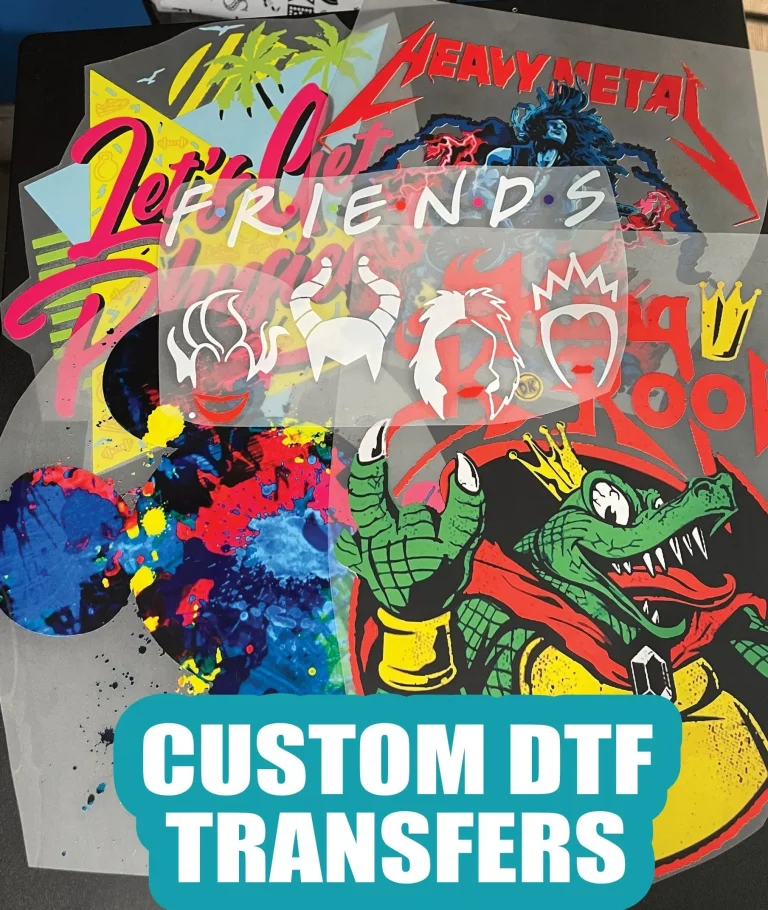

Understanding the Fundamentals of DTF Transfers

Direct-to-Film (DTF) transfers symbolize a revolutionary breakthrough in custom apparel printing by combining cutting-edge technology with user-friendly processes. At its core, DTF printing involves creating a film that holds your desired design, which is then transferred onto a garment or fabric using a heat press. This method allows for high-resolution and vibrant prints that can capture intricate details, surpassing the limitations of traditional printing techniques like screen printing. What truly sets DTF apart is its versatility; it can seamlessly print on a variety of materials, including cotton, polyester, and even blends, making it ideal for diverse applications such as custom clothing, bag designs, and home decor items.

By employing DTF transfers, businesses and individual creators can cater to a broad spectrum of customer needs, driven by an ever-growing demand for unique and high-quality custom merchandise. The key to understanding DTF lies in recognizing its efficiency and adaptability, which radically transform how designs are produced and applied.

Another important aspect of DTF transfers is the technology behind the process. Printing on special film enables vibrant color reproduction that can withstand the rigors of washing and wearing, which is crucial in the apparel industry. The film used in DTF transfers contains a special adhesive that activates under heat, allowing for an excellent bond between the design and the fabric. The result is a durable print that feels as good as it looks, often outpacing other methods in terms of longevity and color accuracy. By embracing these advanced technologies, printers can ensure that their outputs not only meet but exceed customer expectations for quality and durability.

Key Benefits of DTF Printing for Custom Apparel

The advantages of DTF printing are numerous, particularly when it comes to catering to the needs of small businesses and independent printers. One standout benefit is the cost-effective nature of DTF transfers, especially when dealing with small production runs. Unlike screen printing, which can incur high setup costs, DTF allows for more economical production without sacrificing quality. This affordability empowers entrepreneurs to offer personalized products and expand their business sustainably, reducing the barrier to entry in the custom apparel market.

Furthermore, DTF transfers provide a quicker turnaround time for projects. Given the straightforward process of printing onto film and then transferring to fabric, printers can meet tight deadlines without compromising on the detail or quality of their designs. This efficiency not only enhances customer satisfaction but also boosts productivity, allowing businesses to take on more projects and grow their revenue streams.

In addition to cost and efficiency, DTF printing excels in its user-friendly approach. The process requires minimal training, making it accessible for beginners who want to explore custom printing. With just a few basic steps—printing, applying adhesive, and heat transferring—anyone can produce remarkable designs. This simplicity is key in democratizing custom apparel printing, attracting hobbyists and startups alike to engage with DTF technology as they embark on their creative journeys.

Emerging Trends in DTF Printing

As the landscape of DTF transfers continues to evolve, several emerging trends are shaping the future of custom printing. One significant advancement lies in the ink technology used in DTF printing. New formulations enhance the adhesion and durability of prints, making them even more reliable for everyday wear. Moreover, growing environmental concerns have prompted some manufacturers to step up their game by providing eco-friendly ink options, allowing printers to cater to the rising demand for sustainable products without compromising quality.

Another trend gaining traction is the accessibility of affordable DTF printing equipment. As technology has advanced, the price of specialized printers and related tools has decreased, paving the way for small businesses and even home-based entrepreneurs to thrive in the custom apparel market. This influx of accessible technology is democratizing the printing experience, opening doors for creativity and innovation across the industry.

Alongside these advancements, DTF printing is increasingly integrating with e-commerce platforms. With the rise of online retail, many users are looking for unique, customized products that stand out from mass-produced items. By merging DTF services with e-commerce, printers can streamline order processing and offer personalized options tailored to individual customers’ preferences. Moreover, this integration allows for enhanced marketing capabilities, enabling printers to reach more customers and grow their business in an ever-competitive market.

Challenges in DTF Transfer Printing

Despite the many advantages associated with DTF transfers, potential printers must also navigate some challenges inherent to this technology. One significant issue is the initial investment required for setup. While DTF transfers are economical for small runs, the upfront costs associated with purchasing printers, heat presses, and special films can be daunting for startups. Proper budgeting and planning are crucial to ensure long-term success, as investing in high-quality equipment can ultimately pay off in terms of production quality and customer satisfaction.

Quality control is another challenge facing those who venture into DTF printing. Achieving a consistent print quality across different runs can be tricky if equipment settings or materials vary. Calibration of printers is vital, as is the selection of compatible films and inks to maintain high printing standards. Understanding and managing these factors is essential for delivering reliable products that meet customer expectations.

Additionally, mastering the DTF printing process could require considerable practice. As with any new technology, there is a learning curve to understanding the nuances of print quality, material interaction, and press settings. Newcomers might face initial setbacks as they experiment with different fabrics and designs, needing to remain patient and persistent until they achieve optimal results. By investing time and effort into education and experimentation, printers can build expertise, resulting in outstanding and consistent print quality over time.

Best Practices for Success in DTF Transfers

To ensure successful outcomes in DTF printing, aspiring printers should adhere to several best practices. First and foremost is the importance of regular maintenance for printers and heat presses. Keeping equipment clean and well-calibrated can prevent unexpected delays or failures during production. Routine maintenance checks not only enhance the longevity of the machinery but also guarantee consistent output quality, which is vital for building trust with customers.

Additionally, experimenting with various materials can be incredibly beneficial. Not every fabric responds the same way to heat and transfers, so exploring different options can lead to discovering unique finishes or styles for your designs. Developing a solid understanding of how each material interacts with DTF processes will ultimately influence the final product’s look and feel, allowing for more creativity and innovation in design.

Staying current with industry trends and advancements is another vital practice for those in DTF printing. Given that the printing landscape is constantly evolving, participating in online forums, attending trade shows, or subscribing to relevant industry publications can be incredibly beneficial. This ongoing engagement keeps printers informed about new technologies, inks, techniques, and market demands. Adapting to these changes ensures that businesses remain competitive and can continue to meet the desires of a diverse clientele, ultimately leading to success in the world of DTF transfers.

Conclusion: Embracing DTF Transfers for Creative Potential

In conclusion, DTF transfers stand as a transformative force in the field of custom printing, offering an array of benefits including versatility, affordability, and ease of use that are difficult to rival. By understanding the distinct advantages of this printing technology and staying attuned to the latest trends, printers can harness the potential of DTF transfers to create high-quality and distinctive products that resonate with consumers. Whether for professional enterprises or personal projects, DTF printing opens doors to new avenues of creativity, allowing users to express their unique artistry through custom apparel.

By embracing these modern techniques and continuously refining their skills, entrepreneurs and hobbyists alike can unlock a new era of possibilities in custom printing. The future is bright for those willing to take full advantage of DTF technology, as it promises to enhance their offerings and meet the demands of an increasingly discerning market.

Ultimately, the key to success with DTF transfers is not just in understanding the technical aspects but also in nurturing creativity and innovation. As the industry moves forward, staying engaged with new developments and adapting to customer preferences will remain essential strategies for any printer looking to thrive. By effectively leveraging DTF printing’s potential, users can easily establish their brands while delivering personalized, high-quality products that stand out in a competitive landscape.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then heat-pressed onto fabric. This technique distinguishes itself from traditional printing methods by offering exceptional detail, vibrant colors, and the ability to use on various materials such as cotton and polyester.

What are the main benefits of using DTF printing for custom apparel?

DTF printing provides several benefits for custom apparel, including versatility in fabric application, cost-effective production for small runs, and a user-friendly process that requires minimal training. These advantages make DTF transfers an ideal choice for both small businesses and hobbyists looking to create unique apparel.

How does DTF printing compare to other custom apparel printing methods?

Compared to traditional methods like screen printing, DTF printing offers lower costs for small production runs, greater versatility with fabric choices, and easier implementation. This makes DTF transfers a popular option among printers seeking quality and efficiency for custom apparel.

What are the latest trends influencing DTF transfer techniques?

Recent trends in DTF transfer techniques include advancements in ink technology for better adhesion and durability, the emergence of affordable DTF printing equipment, and the integration of DTF services with e-commerce platforms. These trends enhance the overall printing experience and accessibility for users.

Why is quality control important in DTF printing?

Quality control in DTF printing is essential to ensure consistent print outcomes across different jobs. Factors like printer calibration and material suitability play a critical role in achieving high-quality prints, making effective quality management vital for the reputation and success of any custom apparel business.

What are some tips for successful DTF printing?

To achieve success with DTF printing, regularly maintain your equipment to prevent failures, experiment with various fabrics to determine the best results for your designs, and stay informed on industry trends. Engaging with online communities and resources can also help you enhance your DTF printing skills.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing process where designs are printed on film and transferred to fabric using heat and pressure. |

| Advantages of DTF Transfers | Versatile material application, cost-effective for small runs, easy for beginners. |

| Recent Trends | Improvements in ink technology, more affordable equipment, integration with e-commerce. |

| Challenges | Initial investment costs, maintaining consistent quality. |

| Tips for Success | Regular maintenance, experimentation with materials, staying updated on trends. |

Summary

DTF transfers are revolutionizing the custom printing landscape, offering unique advantages that cater to both businesses and hobbyists alike. This innovative method embodies versatility, allowing for intricate designs on a variety of fabrics while remaining cost-effective and user-friendly. As industry trends evolve and technologies advance, DTF transfers promise to unlock new creative possibilities, making it an exciting time to explore this printing technique. Engaging with DTF transfers now could lead to enhanced printing capabilities and a favorable position in the competitive custom merchandise market.