DTF Transfers by Size are an essential consideration for anyone looking to create impactful custom designs using direct-to-film printing techniques. This innovative method allows for vibrant, detailed artwork application on various fabrics, making it perfect for diverse projects, from stylish apparel to promotional materials. When it comes to selecting the right size for DTF transfers, understanding the specific dimensions that suit your project can greatly influence the final result. This guide delves into the effective sizing of DTF transfers, ensuring that your custom printing efforts yield results that truly stand out. Uncover the optimal approaches for sizing DTF transfers to bring your designs to life and elevate your custom printing game.

When exploring the world of direct-to-film (DTF) transfer printing, it’s crucial to grasp the significance of dimensional accuracy in your designs. This cutting-edge custom printing technique has transformed how designs are applied to textiles, providing endless possibilities in both personal and commercial use. Understanding how to measure and size DTF transfers effectively ensures that your creations do not just resonate with an audience but also maintain quality and aesthetics. By examining the appropriate dimensions for direct-to-film transfers, you can make informed decisions for a successful project outcome. Join us as we unravel the intricacies of sizing DTF transfers and optimize every aspect of your custom designs.

Understanding DTF Transfer Printing

DTF (Direct-to-Film) transfer printing is a revolutionary printing technique that allows for highly detailed designs to be applied onto various fabrics. This method involves printing your artwork onto a special film, which is then transferred to the garment using heat and pressure. Unlike traditional printing methods, DTF offers incredible color vibrancy and the ability to print on a diverse range of materials, including cotton, polyester, and blends. The flexibility of DTF also means that whether you’re producing for a small business or a large promotional event, there’s a suitable application for everyone.

This innovative printing technology is gaining popularity among custom printing enthusiasts and professionals alike. With its ability to produce low-volume prints at a competitive cost, DTF transfers are quickly becoming a staple in the apparel industry. Businesses are leveraging DTF transfers to create unique products that cater to customer demands, from personalized apparel to bulk orders for events. As the DTF market continues to grow, understanding its applications and functionalities is essential for staying ahead in the custom printing arena.

Selecting the Right Size for DTF Transfers

Choosing the correct size for your DTF transfers is critical to achieving the best visual results and overall design impact. For small-scale projects such as hats and patches, transfers between 4 to 6 inches in height or width are recommended. This size allows the design to fit neatly without overpowering the item, ensuring it remains stylish and appealing to the eye. Proper sizing in this range enhances the intricate details that DTF printing can produce, making even small designs pop on the fabric.

In contrast, medium-sized projects like t-shirts and sweatshirts typically require designs that are between 8 to 12 inches. This sizing strikes the perfect balance between visual presence and comfort, allowing the design to be bold while fitting within the garment comfortably. For larger items such as banners or promotional materials, designs exceeding 18 inches can turn heads and draw attention effectively. This understanding of sizing DTF transfers is essential in assuring that your projects make a lasting impression.

Best Practices for Sizing DTF Transfers

Implementing best practices in the sizing of DTF transfers can lead to improved aesthetic appeal and production efficiency. One essential practice is conducting test prints before finalizing designs for production. This method not only helps to gauge the fit and visual impact of the transfer but also minimizes the chances of costly mistakes that can arise from poorly sized prints. Adjusting the design based on test outcomes ensures that the final product meets design expectations while enhancing production reliability.

Another crucial aspect is to leave adequate margins around the designs. Margins help prevent the print from looking cramped, giving it a professionally finished appearance. Additionally, assessing the characteristics of the fabric—such as its texture, color, and weight—is vital for achieving optimal results. Lighter fabrics allow for vibrant inks to shine, while textured fabrics may require acquiring different printing techniques to ensure proper adhesion and aesthetics.

Exploring DTF Transfer Sizes for Different Projects

Diverse projects demand varied DTF transfer sizes, reflecting both the intended use and the visual goals of the designs. For instance, small accessories such as bags and caps can capitalize on smaller transfer sizes, typically from 4 to 6 inches, which ensure that the designs are complementary rather than overwrought. Custom printing these items with DTF transfers allows for creative designs to be showcased without making them look cluttered.

Conversely, apparel items like t-shirts and hoodies benefit from medium-sized transfers, typically ranging from 8 to 12 inches. This size range provides significant visibility while still maintaining a balanced appearance. For grand promotional items, utilizing large DTF transfers that exceed 18 inches can be highly effective. These larger prints are capable of showcasing detailed artwork, making them ideal for marketing and attention-grabbing purposes. Understanding how to select the proper size based on the type of project can greatly enhance the quality and effectiveness of the final design.

Latest Innovations in DTF Transfer Printing

The world of DTF printing is continuously evolving, with innovations that enhance the printing process and its output. Among the notable advancements is the introduction of eco-friendly inks specifically designed for DTF transfers. These inks not only provide superior color vibrancy and adherence but are also environmentally responsible, catering to a growing consumer demand for sustainable products. Eco-friendly printing practices serve not just to boost print quality but also to elevate a brand’s marketability, making sustainability an attractive option in the textile industry.

Additionally, the accessibility of DTF printers to smaller businesses represents a significant innovation in the market. With advances in technology, high-quality DTF printing is no longer the domain of only large printing operations; even small enterprises can achieve professional results without hefty investments. This democratization of technology expands creative possibilities for business owners looking to innovate in custom printing. As these innovations permeate the market, they not only enhance the quality of DTF transfers but also contribute to transforming industry standards.

The Impact of Proper Sizing on DTF Transfer Quality

Proper sizing of DTF transfers can dramatically influence the quality of the output. It is vital to match the size of the transfer with both the product type and the design to ensure that the final result is visually appealing. A well-sized transfer enhances the details and colors of the design, ensuring that every element is crisp and vibrant. Incorrect sizing can lead to clumsy layouts, where designs either appear too small and lose impact or are too large and overshadow the item’s overall aesthetics.

Moreover, achieving the perfect size for DTF transfers facilitates better application and adherence to various fabric types. Applying a transfer that fits snugly according to the product’s dimensions allows for even heat distribution and better bonding, reducing the likelihood of peeling or fading post-application. Thus, understanding sizing for DTF transfers not only influences design attractiveness but also the longevity and durability of the prints on fabric.

Frequently Asked Questions

What is the significance of sizing DTF transfers in custom printing?

Sizing DTF transfers correctly is crucial in custom printing as it ensures that your designs fit well on various fabrics, enhancing visual appeal and preventing any awkwardness in placement. Proper sizing affects not just aesthetics but also the durability and adherence of the transfer.

How do I determine the right size for my DTF transfers?

To determine the right size for your DTF transfers, consider the type of product you are applying them to. Small projects like hats may require transfers of 4″ to 6″, while medium projects like t-shirts usually look best with sizes between 8″ to 12″. For large items, such as banners, sizes can exceed 18″ for maximum impact.

What size DTF transfer works best for accessories like bags and hats?

For accessories such as bags and hats, it’s recommended to use smaller DTF transfers ranging from 4″ to 6″. This size allows the design to enhance the accessory without overwhelming it, ensuring a balanced look.

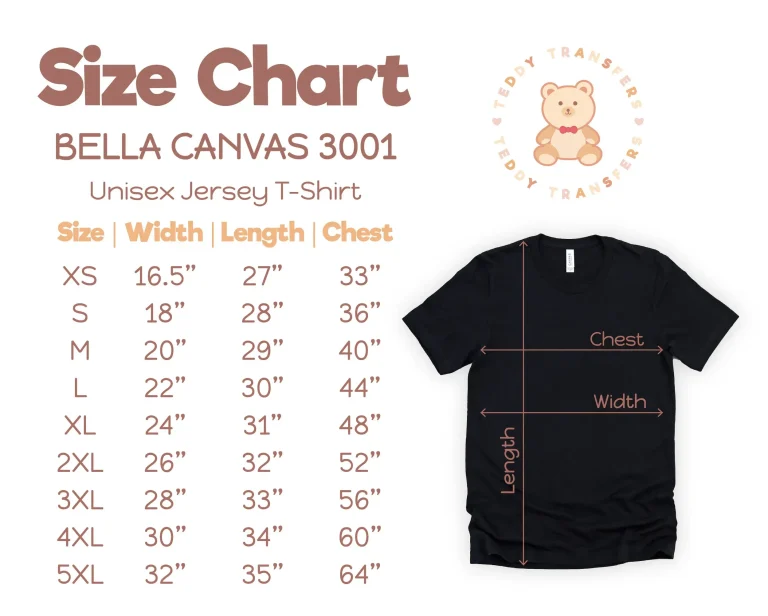

Are there specific size recommendations for DTF print sizes on t-shirts?

Yes, for t-shirts, the optimal DTF print sizes typically range from 8″ to 12″. This size range enhances visibility and provides a clear display of the design while fitting comfortably on the garment.

How can I ensure my large DTF transfers are effective for promotional materials?

To ensure large DTF transfers are effective for promotional materials, use designs that exceed 18″. Larger transfers capture attention effectively, making them ideal for banners or fashion pieces that need to stand out.

What are the best practices for sizing DTF transfers?

Best practices for sizing DTF transfers include conducting test prints to test fit and visual balance, leaving adequate margins around designs, and considering the characteristics of the fabric to ensure optimal adhesion and vibrancy of the transfer.

| Project Size | Recommended Transfer Size | Suitable Applications |

|---|---|---|

| Small Projects | 4″ to 6″ | Accessories (hats, bags, patches) |

| Medium Projects | 8″ to 12″ | T-shirts, sweatshirts, standard apparel |

| Large Projects | 18″ or more | Blankets, banners, promotional materials |

Summary

DTF Transfers by Size are crucial for ensuring quality in custom printing. As this guide reveals, the choice of transfer size can greatly impact the aesthetic and effectiveness of the final product. Whether creating small accessories or large promotional items, aligning the right transfer size with project requirements is essential. By adhering to the size recommendations and best practices outlined, you can maximize the visual appeal and overall success of your projects, allowing them to stand out in the competitive landscape of custom printing.