DTF Transfers, or Direct to Film transfers, are transforming the landscape of textile printing with their innovative approach to design and application. This cutting-edge DTF printing technology allows businesses to print vibrant, high-quality designs onto various fabrics, resulting in exceptional custom merchandise. With the numerous DTF transfer benefits, including versatility and cost-effectiveness, it’s becoming a preferred choice for entrepreneurs looking to elevate their offerings. In this guide, we will delve into the essentials of DTF transfers, highlight practical DTF printing tips, and explore how to use DTF transfers effectively to maximize their appeal and performance. Stay tuned to unlock the power of DTF transfers and take your branding to new heights.

Often referred to as Direct to Film printing, DTF transfers encompass a groundbreaking method of applying intricate designs onto fabrics. This process utilizes a special film that captures images with stunning detail and color fidelity, making it a standout option for businesses in need of customizable merchandise. Known for their remarkable durability and adaptability to various textile types, these transfers have quickly gained traction among printing enthusiasts. In this exploration of DTF technology, we will examine the unique advantages it offers, practical insights for optimal usage, and emerging trends in the printing industry. Join us as we uncover the essentials and potential of this dynamic printing solution.

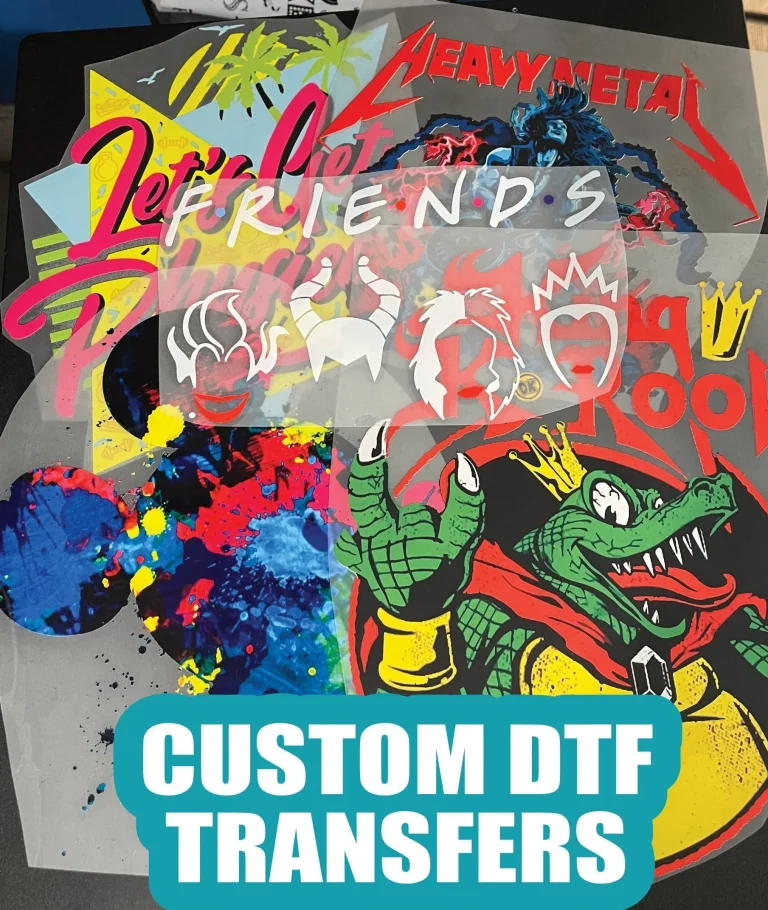

Understanding DTF Printing Technology

DTF printing technology stands for Direct to Film transfer, a method that enables vibrant and intricate designs to be printed directly onto a special transfer film. This process is relatively straightforward; it begins with creating the design digitally, which is then printed using specialized inks. The printed film can subsequently be transferred onto fabrics using a heat press, allowing for detailed designs that adhere well to various materials. The versatility of DTF transfers makes them suitable for multiple applications, ranging from apparel to promotional merchandise, catering to a diverse range of business needs.

One of the key aspects of DTF printing technology is its ability to reproduce vivid colors and fine details. This quality is achieved through the unique ink formulation and the transfer film’s properties. High-quality films are engineered to provide excellent adhesion and durability, ensuring that the final product retains its appearance even after multiple washes. As businesses continue to seek innovative ways to express their brand identity through custom merchandise, DTF technology provides a reliable solution that combines both aesthetic appeal and practical performance.

Key Benefits of DTF Transfers for Businesses

The benefits of utilizing DTF transfers are numerous, particularly for small businesses and entrepreneurs. One of the most significant advantages is the cost-effectiveness of small production runs. Unlike traditional screen printing, which often requires large quantities to be economically viable, DTF allows for short runs without sacrificing quality. This means businesses can cater to niche markets or specific customer requests without hefty upfront costs, making it ideal for custom projects.

Additionally, DTF transfers offer excellent print longevity, which is essential for customer satisfaction. The prints produced are not only vibrant but also durable, standing up to regular use and washing. This reliability fosters trust between businesses and their clients, as customers are more likely to return for products that maintain their quality over time. By incorporating DTF printing into their operational model, businesses can significantly improve their product offerings and customer retention rates.

Practical Tips for Effective DTF Printing

To maximize the benefits of DTF transfers, businesses should adhere to specific practices that enhance the printing process. First and foremost, choosing high-quality DTF films is paramount. Investing in superior films will yield better adhesion and longevity, ensuring that prints stand the test of time. Different fabrics require different types of films, so it’s essential to select the correct one for the material at hand. Additionally, performing test transfers on sample fabrics can help fine-tune settings before committing to final runs.

Another critical aspect is the pre-treatment of fabrics prior to applying DTF transfers. Pre-treatments improve ink absorption and enhance the durability of the final print. Testing various pre-treatment solutions on different fabric types can lead to improved results. Furthermore, mastering the correct temperature and pressure settings on heat presses significantly impacts transfer success. As a rule of thumb, maintaining settings within the recommended range, usually around 320-330°F, is vital for achieving optimal results.

Innovations and Trends in DTF Transfers

The landscape of DTF transfers continues to evolve, with new innovations enhancing the technology’s capabilities. Recent developments have focused on improving the printing process and expanding the variety of designs achievable through DTF. Businesses have started integrating advanced printing techniques that allow for greater detail and color richness, catering to increasingly sophisticated consumer demands. This trend signifies that DTF is not just keeping pace with industry changes but is also at the forefront, enabling creative designs that were previously unattainable.

Moreover, as more businesses adopt DTF technology, the market for DTF-specific materials, inks, and equipment is also thriving. Suppliers are developing highly specialized products that streamline the DTF process, making it easier for businesses to implement this technology efficiently. As more entrepreneurs recognize the effectiveness of DTF printing, the potential for unique, personalized offerings will continue to grow, positioning DTF as a key player in the custom merchandise market.

Incorporating DTF Transfers into Your Branding Strategy

Incorporating DTF transfers into a branding strategy can greatly enhance a business’s visibility and customer connection. The ability to create unique and personalized merchandise allows companies to express their brand identity more vividly. For example, businesses can design custom apparel that resonates with their target audience, making them feel more connected to the brand. This level of personalization not only engages customers but can also lead to increased brand loyalty, as people are likely to promote products that reflect their personal style.

Furthermore, leveraging DTF transfers allows for creative marketing opportunities. Brands can create limited-edition items or seasonal products that align with current trends, sparking interest and excitement among customers. As consumers increasingly look for products that reflect their individuality, offering customizable options via DTF transfer becomes a powerful tool for businesses striving to differentiate themselves in a crowded marketplace. By embracing the capabilities of DTF, companies can reinforce their branding while simultaneously driving sales.

Essential Resources for DTF Printing Success

For businesses looking to excel in DTF transfers, accessing quality resources can provide valuable insights and practical guidance. Websites and blogs focused on printing technologies, like Printavo and Siser, are excellent starting points. These platforms offer a wealth of information, including troubleshooting tips, equipment recommendations, and updates on the latest trends in DTF printing. Engaging with these resources can help businesses stay abreast of innovations that enhance their operations and product offerings.

Additionally, online forums and communities dedicated to DTF printing allow for networking and knowledge sharing among professionals in the field. Participating in discussions can provide real-world insights into the best practices and common challenges faced by others. By cultivating a network of fellow DTF users, businesses can gain access to countless tips and strategies, further empowering them to maximize the potential of DTF transfers in their operations.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct to Film Transfers, are a modern printing method where designs are printed onto a special film using specialized inks. This film is then heat pressed onto various fabrics, allowing for vibrant, long-lasting prints that are ideal for apparel and promotional items.

What are the benefits of using DTF printing technology?

The benefits of DTF printing technology include its versatility as it works on a variety of fabrics, the ability to produce bright, vivid colors, and cost-effectiveness for small businesses. DTF Transfers require lower initial production costs compared to methods like screen printing, making them ideal for custom merchandise.

What tips should I follow for successful DTF Transfers?

For successful DTF Transfers, choose high-quality films, pre-treat fabrics to enhance adhesion, and adjust temperature and pressure settings appropriately during the transfer process. Conducting test transfers can also help ensure consistent quality.

How can I enhance my business branding with DTF Transfers?

You can enhance your business branding with DTF Transfers by creating custom branded merchandise. Utilize DTF technology to design unique, personalized items that strengthen customer loyalty and boost visibility for your brand.

What maintenance is required for equipment used in DTF printing?

Regular maintenance of printing equipment and heat presses is crucial for DTF printing. This includes cleaning, checking for wear and tear, and calibrating settings to ensure consistent quality and prevent downtime, ultimately leading to better customer satisfaction.

Are there recent trends in DTF Transfers that businesses should know?

Yes, recent trends in DTF Transfers include increased adoption among small and medium-sized businesses due to their cost-effectiveness and flexibility for short-run items. Additionally, advancements in DTF technology are enabling more intricate designs, catering to the growing demand for unique and personalized products.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A modern printing method where designs are printed on a special film and then transferred to various fabrics using heat. |

| Advantages of DTF Transfers | 1. Versatility: Works on various fabrics like cotton and polyester. 2. Vibrant Colors: Produces bright, long-lasting prints. 3. Lower Costs: More economical for small runs compared to screen printing. |

| Tips for Maximizing DTF Transfers | 1. Use high-quality films for better adhesion. 2. Pre-treat fabrics to enhance durability. 3. Set the right temperature and pressure during transfers. 4. Incorporate branding into designs. 5. Maintain equipment to ensure quality. |

| Recent Trends and Developments | 1. Increased adoption by small and medium businesses in 2023. 2. Ability to create intricate designs, meeting market demands for uniqueness. |

| Resources for Further Learning | 1. Printavo Blog: Insights on DTF and printing technologies. 2. Siser North America: Resources focused on DTF applications. |

Summary

DTF Transfers are transforming the way businesses approach fabric printing, enabling them to deliver high-quality, vibrant designs with greater efficiency. By leveraging the versatility and cost-effectiveness of DTF technology, companies can significantly enhance their product offerings. As the industry continues to embrace DTF transfers, businesses that adapt to these advancements are set to stand out in a competitive market, ensuring their branding resonates and engages customers effectively.