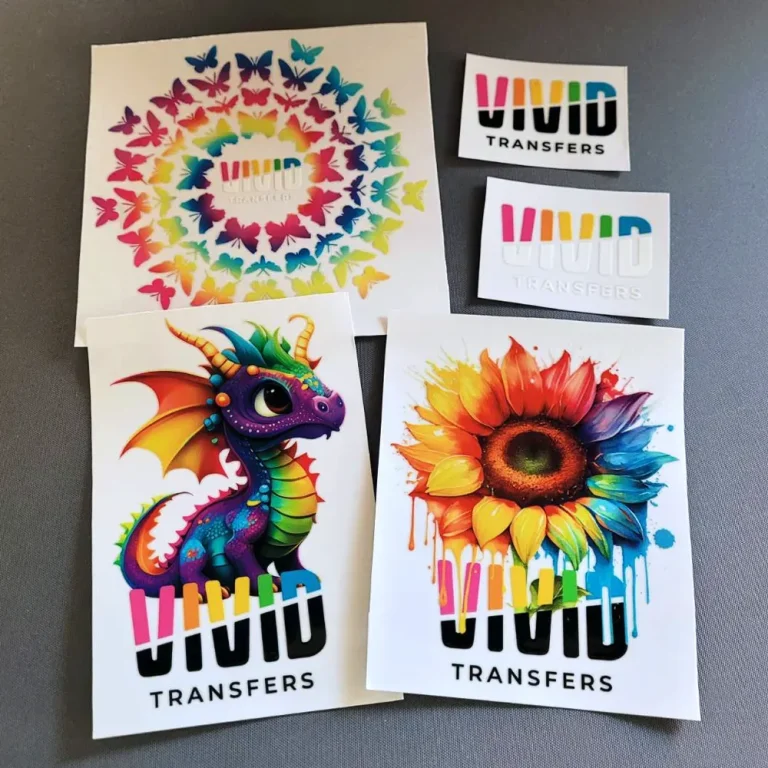

UV DTF transfers represent a significant leap in the world of printing technology, seamlessly blending UV printing benefits with the efficiency of transfer printing. This innovative method allows for stunning vibrant prints on a wide variety of surfaces, including textiles, metals, glass, and even wood. As the demand for high-quality, durable, and custom printing solutions continues to rise, UV DTF transfers are emerging as a front-runner in meeting these needs. The quick curing process used in UV DTF ensures that colors are not only bright but also resistant to fading, setting it apart from traditional methods. Whether you’re a business owner looking for promotional products or a creative individual seeking unique merchandise, UV DTF transfers can transform your vision into reality with remarkable results.

Exploring alternative terms for UV DTF transfers reveals a captivating realm of direct-to-film solutions that elevate print quality and versatility. Known for its ability to produce vibrant graphics, UV DTF printing employs advanced curing technologies that ensure durability and rich colors across various materials. This modern approach to transfer printing has garnered attention in industries focused on custom printing and personalized products, offering exceptional applications for both hard and soft surfaces. With the rise of custom and promotional merchandise, this method is well-positioned to cater to a discerning audience seeking standout designs. By incorporating the latest innovations in UV printing, creators can achieve impressive results that reflect their unique aesthetic and branding needs.

Understanding UV DTF Transfers and Their Advantages

UV DTF transfers combine the precision of UV printing with the versatility of transfer technology. This innovative approach enables high-quality imaging on a variety of materials, from textiles to metal and wood. The process utilizes UV light to instantly cure the ink, ensuring that colors remain vibrant and details crisp. With its capacity to produce durable and eye-catching prints, UV DTF has become increasingly sought after in custom printing applications.

Compared to traditional transfer printing methods, UV DTF offers a range of advantages, including quicker turnaround times and enhanced longevity of prints. The ability to print on diverse surfaces with one method allows businesses to expand their product offerings without the need for specialized processes for each material. As a result, UV DTF transfers are an excellent choice for manufacturers looking to provide high-quality, custom solutions.

Step-by-Step Guide to Using UV DTF Transfers

To start with UV DTF transfers, the preparation of your substrate is essential. Always clean the surface carefully, whether you are working with hard surfaces like glass and metal or textiles. Any contaminants can affect adhesion and the overall quality of the transfer. Utilizing a lint roller can be particularly useful for fabrics to ensure that no fibers interfere with your design.

Once your substrate is ready, you will need to create a captivating design. Using graphic design software helps in producing images that fully utilize the vibrancy of UV DTF prints. It’s essential to work in the correct format to ensure your design adheres perfectly when printed. This stage sets the foundation for your final product, so invest time in making it vibrant and appealing.

The Curing Process: Key to Vibrancy in UV DTF Transfers

One critical aspect of the UV DTF printing process is curing. After printing your design onto the transfer film, it goes through a UV light curing stage that solidifies the inks immediately. This rapid curing not only enhances the color vibrancy but also increases the print’s durability against environmental factors and wear. Proper curing ensures that your prints maintain their rich colors and intricate details.

While the curing time can vary based on equipment, following manufacturer guidelines is crucial for success. Over-curing or under-curing can compromise print quality, leading to fading or peeling. Therefore, understanding the specifics of your UV printer will substantially impact the final outcome of your UV DTF transfers.

Best Materials for UV DTF Transfers

Selecting the right materials is vital for achieving stunning UV DTF prints. High-quality transfer films and substrates will significantly impact the vibrancy and durability of your final product. Investing in superior materials not only enhances print quality but also ensures that your designs withstand the test of time, making them ideal for custom apparel and promotional products.

For fabrics, consider using those specifically designed for UV printing to optimize ink adhesion and surface compatibility. Rigid surfaces like metal and glass require coatings that facilitate the transfer process. Always ensure that the materials are compatible with UV DTF technology to achieve the most impactful results.

Troubleshooting Common Issues in UV DTF Printing

Despite the effectiveness of UV DTF transfers, some common issues may arise during the printing process. Misalignment during the transfer stage can lead to spoiled prints, so double-check alignment settings before heat application. Additionally, temperature and pressure settings are crucial; incorrect configurations can affect adhesion and print quality.

If you notice fading or peeling in your finished products, it may be time to evaluate your curing process or materials. Keeping a consistent workflow and noting any adjustments made during printing can aid in troubleshooting recurring problems. By staying vigilant and adjusting settings as needed, you can enhance the reliability of your UV DTF transfer results.

Innovative Applications of UV DTF Transfers

UV DTF transfers have opened the door to many innovative applications, especially in the custom printing landscape. From personalized gifts to marketing collateral, the versatility of this technique allows for customized solutions that cater to diverse client needs. Businesses can utilize UV DTF to create eye-catching promotional materials that resonate with their audience and stand out in competitive markets.

Additionally, the use of UV DTF transfers in apparel customization is on the rise. Custom t-shirts and accessories adorned with vibrant prints have become increasingly popular as individuals seek ways to express their unique style. This technology supports creativity, allowing for intricate designs and vivid colors that make every piece special, thereby catering to both consumers and businesses.

Frequently Asked Questions

What is UV DTF printing and how does it work?

UV DTF printing, or Direct to Film printing, utilizes UV light to cure ink as it is printed onto a special film. This method allows for the creation of vibrant prints that can be applied to various surfaces, including fabrics, metal, and wood, resulting in durable and high-quality graphics.

What are the benefits of using UV DTF transfers for custom printing?

UV DTF transfers offer numerous benefits for custom printing, including vibrant colors, excellent durability, and versatility across different substrates. This innovative method is particularly advantageous for creating promotional products and personalized merchandise that require high-quality designs.

How do I prepare my substrate for UV DTF transfer printing?

To prepare your substrate for UV DTF transfer printing, ensure it is clean and free from debris, oils, or dirt. Use a lint roller or a soft cloth to clean the surface. Proper preparation is essential for achieving a stunning and flawless transfer.

What types of designs work best with UV DTF transfers?

Vibrant and intricate designs tend to work best with UV DTF transfers. The UV inks are designed to showcase bright colors and fine details, making them ideal for custom graphics, promotional products, and artwork that stand out.

What materials can I use for UV DTF transfers?

UV DTF transfers can be applied to a wide range of materials, including textiles, wood, metal, and glass. This versatility allows businesses and artists to innovate and create products across various industries and applications.

How can I ensure high-quality results when using UV DTF printing?

To ensure high-quality results with UV DTF printing, use high-quality materials, test different temperature and pressure settings on your heat press, and practice the transfer technique. Following these tips will help achieve the best possible final product.

| Steps for Using UV DTF Transfers | Description |

|---|---|

| 1. Preparation | Ensure substrate is clean and free from debris. |

| 2. Design Creation | Create the design in graphic software, ensuring compatibility with printer. |

| 3. Printing | Load transfer film into UV printer and print the design. |

| 4. Curing | Expose the printed film to UV light to cure the ink. |

| 5. Transfer Process | Position the cured print on substrate and use heat press. |

| 6. Finalization | Allow to cool and peel away transfer film, inspecting the final product. |

Summary

UV DTF Transfers present an exciting opportunity for high-quality printing, bringing together the advantages of UV printing technology with transfer methods. By meticulously following the outlined steps, users can achieve vibrant and durable results on a variety of substrates, ranging from textiles to metal and glass. This versatile printing option is set to revolutionize how businesses and creatives deliver customized products, ensuring that each item stands out in a competitive market. With advancements in technology enhancing color vibrancy and curing times, the potential for UV DTF Transfers is only bound to grow, making it an essential technique for anyone looking to elevate their printing capabilities.