DTF transfers, or Direct-to-Film transfers, are rapidly transforming the custom printing landscape, providing unparalleled versatility for creative applications. This innovative printing technology allows individuals and businesses to produce eye-catching, full-color designs that adhere seamlessly to a variety of materials, from fabrics to promotional items. The precision and flexibility inherent in custom DTF transfers cater to a range of design needs, making them ideal for everyone from boutique apparel shops to large-scale graphic producers. With numerous DTF transfer sizes available, you can achieve stunning results, whether you are crafting intricate small logos or large-scale promotional graphics. As we delve deeper into this topic, uncover how DTF printing technology not only enhances product aesthetics but also supports eco-friendly practices in the printing world.

Direct-to-Film printing represents a cutting-edge advancement in the realm of design transfer techniques. Often referred to as DTF technology, this method enables creators to transfer vibrant, detailed graphics onto various substrates with ease. With DTF transfers gaining traction, it’s essential to understand their capabilities, including various application sizes and how they can elevate your branding efforts. Additionally, the eco-friendly alternatives available within DTF processes contribute to a sustainable future in custom printing, appealing to the environmentally conscious market. As we explore the exciting world of DTF and its diverse applications, we’ll reveal how its unique features can revolutionize your approach to custom designs.

Understanding Direct-to-Film (DTF) Transfers

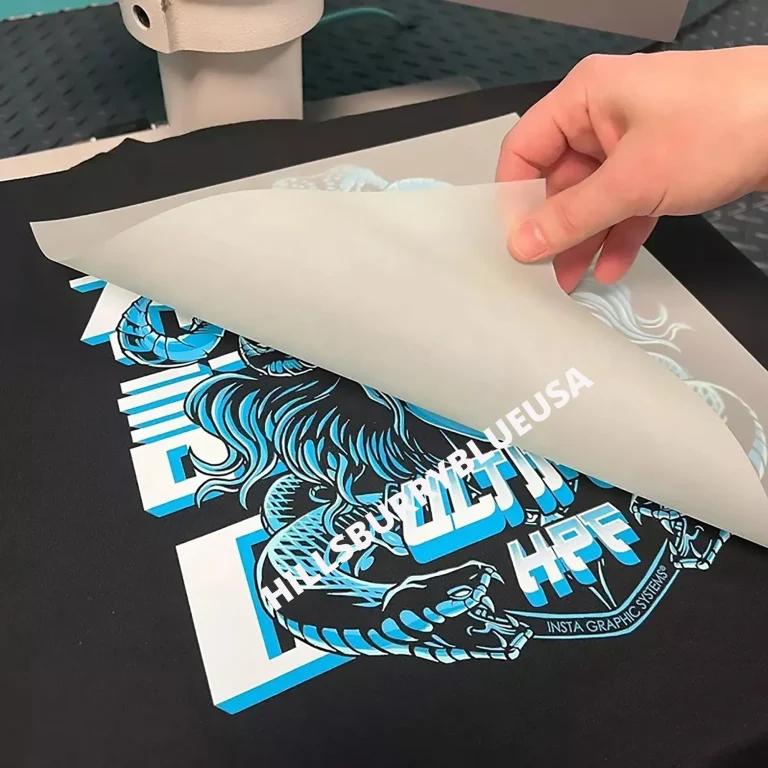

Direct-to-Film (DTF) transfers have emerged as a game-changing technology in the custom printing industry. This innovative method consists of printing designs on a specialized film that serves as a transfer medium. The process begins by printing the artwork onto the film, followed by the application of a powdered adhesive, which is then heat-cured. The final step involves heat pressing the film onto various materials, allowing for vibrant colors and detailed designs to be transferred with remarkable clarity. DTF transfers are especially popular for their ability to handle intricate graphics, making them the ideal choice for brands looking to make a statement through custom designs.

What sets DTF transfers apart from other printing techniques, such as screen printing or heat transfer vinyl, is their versatility and efficiency. The ability to switch between different design sizes without significant setup changes means that businesses can respond quickly to customer needs. Whether producing small promotional items or large-scale apparel prints, DTF technology adapts to various requirements, ensuring consistent quality across all sizes of transfers. This adaptability is particularly beneficial for custom jobs, enabling print services to meet diverse client requests efficiently.

Versatile Sizes for Your Custom Printing Needs

One of the standout features of DTF transfers is their availability in a wide range of sizes. This versatility allows businesses to cater to different markets and customer preferences. For example, smaller DTF transfers are perfect for branding small items like business cards or tags, where intricate details are required for effective branding. On the other hand, medium to large-sized transfers are ideal for apparel, banners, or home décor items, where bold visual impact is paramount. This flexibility means that companies can offer a wider array of products without sacrificing quality or detail.

Moreover, the ability to customize DTF transfer sizes opens up new opportunities for creative expression. Fashion designers can experiment with oversized graphics that dominate the fabric, while crafters can utilize smaller transfers to enhance personal projects. This range also allows for experimentation with multi-layer designs, where different sizes can be layered to create depth and dimension in the finished product. Ultimately, the versatile sizing of DTF transfers supports the unique demands of various industries, from fashion to promotional materials, making it a vital resource in custom printing.

Eco-Friendly DTF Transfers: Sustainable Printing Solutions

As awareness of environmental impact continues to rise, eco-friendly DTF transfers have become a preferred choice for many conscious consumers and businesses. Innovative DTF printing technology has made it possible to incorporate sustainable materials, such as bio-based inks, which are derived from renewable resources. These inks not only reduce the carbon footprint associated with traditional printing methods but also maintain vibrant colors and exceptional print quality. By opting for eco-friendly DTF transfers, companies can align themselves with environmentally sustainable practices, appealing to an audience that values eco-conscious choices.

In addition to bio-based inks, DTF processes are increasingly utilizing lower volatile organic compound (VOC) materials, further minimizing environmental impact. These lower VOC options create a safer workspace for printers and contribute positively to air quality, making DTF printing a responsible choice for manufacturers. As businesses continue to adopt green practices, eco-friendly DTF transfers not only fulfill market demands for sustainability but also enhance a company’s reputation among environmentally aware consumers, establishing stronger brand loyalty.

Innovative DTF Printing Technology: A Game Changer

The rapid advancements in DTF printing technology have greatly influenced how custom designs are created and applied. DTF printing guarantees high-resolution images with intricate detail, which traditional printing methods sometimes cannot achieve. This level of precision means that brands can produce visually stunning promotional items and apparel, ultimately attracting more customers and elevating their market presence. Businesses that adopt DTF technology can differentiate themselves by offering superior-quality prints that meet the increasing consumer demand for personalization and creativity.

Another notable advantage of the latest DTF printing technology is the speed at which designs can be produced. With significantly reduced setup times compared to traditional printing methods, small businesses can manage orders more efficiently, fulfilling customer needs swiftly and effectively. This efficiency not only enhances customer satisfaction but also streamlines overall production processes, allowing businesses to focus more on innovation and growth. Investing in DTF printing technology means staying competitive in an ever-evolving market that prioritizes quality and quick turnaround.

Cost-Effective Solutions with DTF Transfers

Cost-effectiveness is one of the most appealing characteristics of DTF transfers for small businesses and startups in the custom printing industry. As the DTF printing process has matured, the costs associated with producing DTF transfers have decreased significantly, allowing smaller shops to invest in high-quality printing without incurring the hefty setup fees commonly associated with traditional screen printing. This reduced financial barrier means that businesses can take on a broader range of projects, from one-off custom items to larger bulk orders, without compromising their margins.

Furthermore, the flexibility of DTF printing means that printers can easily adjust the volume of their orders according to demand. This adaptability allows for smaller batch productions, meaning that businesses can respond to niche client requests without overcommitting resources. The capacity to cater to both small and large orders presents a significant advantage, empowering companies to retain customers who require personalized solutions, ultimately driving repeat business and strengthening client relationships.

Enhancing Market Growth through DTF Printing

The market for DTF printing is experiencing notable growth, propelled by the increasing demand for customized products across various sectors. The fashion industry, in particular, is witnessing a significant rise in personalized clothing items, where consumers are looking for unique designs that reflect their individual styles. DTF transfers provide the ideal solution for these market dynamics, offering brands the ability to produce high-quality, customized apparel while also meeting rapid production demands.

Moreover, other industries such as home décor and promotional products are extending the growth potential for DTF printing. Businesses that embrace the technology can quickly pivot to offer a diverse product range, meeting consumer needs while enhancing their market presence. As customization continues to trend upward, those who invest in DTF printing technology position themselves at the forefront of the industry, ready to capitalize on evolving consumer preferences and the future of personalized products.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, are a modern printing method that transfers high-quality designs onto fabrics and other surfaces. The process involves printing an image onto a special film, applying powder adhesive, and curing it before heat pressing onto the target material, resulting in vibrant and detailed prints.

What sizes are available for custom DTF transfers?

Custom DTF transfers come in a variety of sizes, from small designs suitable for logos to large formats for apparel prints. This size flexibility allows businesses to cater to various design needs, making DTF transfers suitable for both small promotional items and large bulk orders.

How does DTF printing technology ensure quality and detail?

DTF printing technology utilizes advanced methods that produce high-resolution images with intricate detail. The combination of high-quality materials and precise application ensures that DTF transfers maintain vibrant colors and sharp features, making them ideal for custom apparel and promotional products.

Are eco-friendly DTF transfers available?

Yes, many DTF processes incorporate eco-friendly practices, such as using bio-based inks and lower VOC materials. This commitment to sustainability reduces the environmental impact of the printing process while ensuring that the quality of the transfers remains high.

How cost-effective are DTF transfers compared to traditional printing methods?

DTF transfers are generally more cost-effective than traditional printing methods like screen printing, especially for small orders. The reduced setup costs and flexibility in ordering small quantities means that businesses can efficiently meet diverse client demands without significant financial strain.

What industries benefit most from DTF printing technology?

DTF printing technology is beneficial across various industries, notably in fashion, promotional products, and home décor. The ability to create custom designs and accommodate varying sizes makes DTF transfers increasingly popular among businesses looking to fulfill personalized consumer demands.

| Key Point | Description |

|---|---|

| DTF Transfers Defined | A modern method for transferring designs onto fabrics with remarkable detail and vibrancy. |

| Versatility in Sizes | Available in small, medium, and large, accommodating various design needs across industries. |

| Quality of Prints | Produces high-resolution images with intricate details, crucial for custom apparel. |

| Cost-Effectiveness | More affordable for small businesses, allowing for smaller order quantities without high setup fees. |

| Environmentally Friendly | Uses bio-based inks and lower VOC materials for a sustainable printing process. |

| Market Growth | Projected significant growth due to rising customization demand in fashion and home décor. |

| Adoption Trends | Easily adapts between sizes, appealing to businesses for quick turnaround on custom jobs. |

Summary

DTF transfers stand out as a game-changer in the printing industry, bringing forth a multitude of possibilities for users seeking exceptional customization. By exploring the various sizes of DTF transfers, businesses can effectively cater to diverse design demands while ensuring outstanding quality and cost efficiency. As this innovative technology continues to advance, it’s shaping up to be a crucial component in the future of customizable printing solutions.