DTF transfers, or Direct-to-Film printing, have revolutionized the world of custom apparel by providing vibrant, high-quality designs that can be transferred onto various fabrics with ease. This innovative printing method is ideal for brands looking to showcase their creativity, allowing them to produce everything from small logos on casual t-shirts to larger graphics on hoodies and outdoor banners. One of the primary advantages of DTF transfers is their versatility, as they can be tailored to different DTF printing sizes, accommodating various garment dimensions seamlessly. As businesses increasingly turn to custom apparel printing, understanding how to navigate transfers for different sizes becomes essential for creating impactful designs that resonate with consumers. Join us as we delve into the world of large format DTF printing and explore the significant role size plays in achieving visual appeal and quality.

When it comes to garment decoration, utilizing direct-to-film technology offers a unique approach to printing on fabrics. This technique, often referred to as DTF printing, captures vibrant colors and intricate designs, making it perfect for custom apparel. With the ability to customize transfer sizes from small to large, this printing method ensures that each design is tailored to fit its intended application, whether it’s a delicate design for a fitted tee or a bold graphic for a spacious hoodie. Diving deeper into the topic of DTF, we will examine how to effectively manage the challenges associated with applying transfers across various dimensions, as well as innovations that are shaping this growing technique. Understanding these concepts will empower designers and businesses to maximize the potential of their product offerings in an increasingly competitive market.

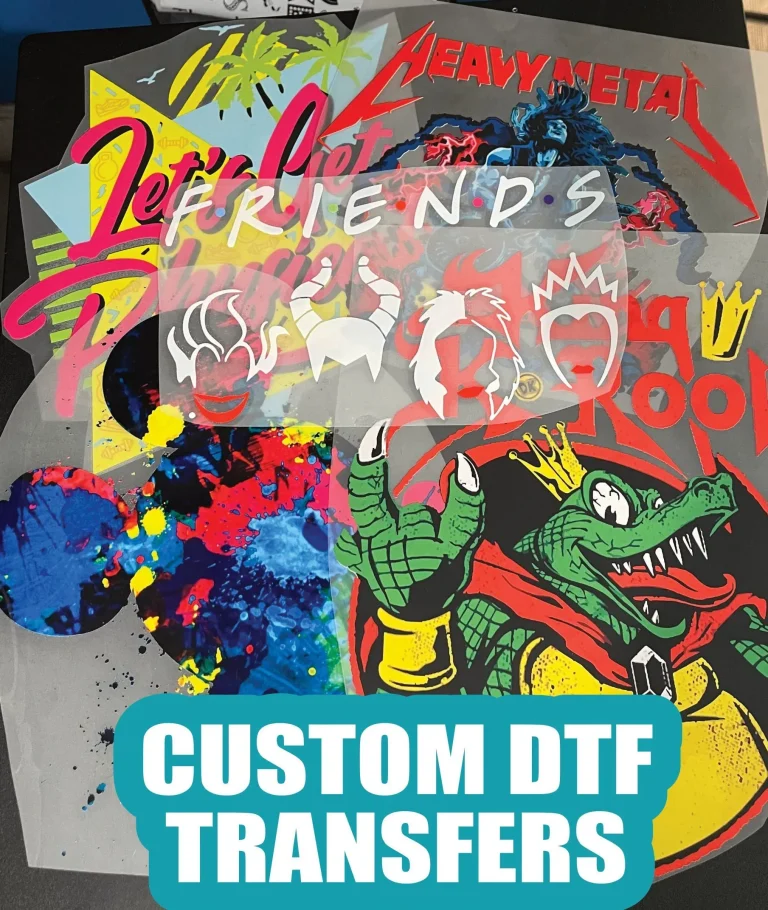

The Versatility of DTF Transfers

Direct-to-Film (DTF) transfers have established themselves as a versatile printing option for custom apparel, thanks to their ability to accommodate a multitude of sizes, from delicate, intricate designs to bold, expansive graphics. This adaptability is crucial in today’s fashion market where consumers demand personalization and unique pieces. The flexibility of DTF printing allows designers to experiment with different transfer sizes without compromising quality, making it an appealing choice for both small-scale projects and larger commercial runs.

The true power of DTF transfers lies in their capacity to cater to diverse garment needs. Small logos on a stylish t-shirt can engage customers in one context, while larger graphics on hoodies or banners can create impactful displays in another. This range in size not only provides a canvas for creativity but also enhances the usability of printed designs across various promotional and personal applications. By leveraging the advantages of DTF technology, businesses can effectively adapt their offerings to meet customer demands.

Optimal DTF Printing Sizes

Choosing the right size for DTF transfers is fundamental to ensuring a design’s success. Unlike traditional printing methods that often come with restrictions, DTF printing enables custom sizes tailored specifically for each project. Whether you are scaling down for a subtle, sophisticated touch or enlarging a design for a bold statement, maintaining clarity and vibrancy is paramount. Designers must understand the various DTF printing sizes available and how to adjust their files accordingly, ensuring that even the smallest details translate effectively to the final product.

Scaling designs for DTF printing requires careful consideration of both the dimensions and the nature of the artwork. Using LSI techniques, designers can optimize their images for various sizes while avoiding pitfalls such as pixelation, which often results from poor resizing. Engaging with precise transfer sizing empowers creators to present professional-grade designs, appealing to clients who seek both quality and creativity in their custom apparel.

The Importance of Machine Calibration

Proper machine calibration is crucial to the success of DTF printing, especially when dealing with various transfer sizes. Each DTF printer is unique, with different specifications and capabilities that require careful adjustment based on the size of the transfer being printed. Calibration influences everything from the placement and adherence of the transfer to the quality of the final output. By fine-tuning these settings, users can ensure that even large DTF prints maintain their integrity throughout the application process.

Furthermore, today’s advanced DTF printers often feature automatic adjustments for size, reducing the burden on operators. However, a deeper understanding of how machines work is beneficial for troubleshooting issues during production runs. By mastering the calibration process, printers can consistently achieve high-quality results across diverse transfer sizes, resulting in professional applications that enhance the visual appeal of custom apparel.

Material Selection for DTF Transfers

Selecting the right materials is a foundational step in the DTF transfer process. The choice of film and adhesive significantly impacts the overall quality of the final product, particularly when attempting to apply intricate designs on various fabrics. When dealing with larger prints, high-quality films designed for robustness and clarity become even more essential. As available technologies evolve, understanding these advancements in film production becomes a key advantage for designers seeking to enhance the quality and vibrancy of their DTF prints across all sizes.

The compatibility of different films with diverse substrates, such as cotton, polyester blends, and specialty materials, can dictate the success of a transfer. Designers must familiarize themselves with film types and their performance across different garment sizes to ensure durability and aesthetic appeal. By doing so, they can create eye-catching prints that withstand the test of time, which is particularly vital in industries where custom apparel is a staple.

Current Trends in Custom Apparel Printing

As the demand for custom apparel heats up, understanding the latest trends in DTF printing becomes increasingly important. Current market insights indicate a growing preference for versatility in design size, allowing for extensive customization that meets individual customer needs. This trend is particularly significant as consumers seek more unique, tailored experiences in their clothing choices. Brands leveraging these insights can strategically position themselves as leaders in the competitive landscape of custom apparel through innovative DTF programming.

Moreover, advancements in technology are continuously emerging, offering up-to-date solutions that cater to both small and large-scale printing projects. New films and adhesive technologies now permit highly detailed designs that remain true to their colors and depth, contributing to a rich user experience. By staying informed and adapting to these trends, designers and printers can effectively meet market needs and exceed client expectations.

Technical Considerations in DTF Transfers

Navigating the intricacies of DTF transfer printing involves recognizing and addressing various technical challenges, particularly when scaling for larger designs. Issues like ‘ghosting’—a phenomenon where unintended marks appear on prints—can detract from the final product’s quality. Understanding the underlying causes, such as incorrect temperature or pressure settings, allows creators to modify their processes effectively, ensuring a superior finished transfer regardless of the design’s size.

Technical proficiency not only aids in overcoming these challenges but also enhances overall productivity in DTF printing operations. Workshops and training sessions focusing on machine handling and material behavior can provide critical insights that lead to desired outcomes. By fostering an environment of continual learning and experimentation, those involved in the DTF printing space can achieve remarkable success in their projects, from expansive graphics to delicate embellishments.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, involve a process that prints designs onto a special film before transferring them onto various fabric types. This method allows for vibrant and detailed graphics on custom apparel, ranging from t-shirts to hoodies. The DTF printing technique is particularly advantageous due to its versatility in handling different sizes and materials.

What sizes are available for DTF printing transfers?

DTF printing transfers come in a variety of sizes, accommodating anything from small logos of 3 inches to large graphics of 24 inches or more. Understanding DTF printing sizes is crucial for achieving the desired visual impact and ensuring that details are preserved during the transfer process. Experimentation with different sizes can help designers find the optimal fit for their apparel.

How do I ensure quality when using DTF transfers for larger designs?

To maintain quality in larger DTF transfers, ensure proper printer calibration and select appropriate films that can handle larger prints without compromising vibrancy or detail. Additionally, managing application variables such as temperature and pressure is essential to avoid potential issues, like the ghosting effect, that can impair larger designs.

Can DTF transfers be used on various materials?

Yes, DTF transfers are compatible with a wide range of materials, including cotton, polyester, and blends. The choice of film and adhesive type plays a vital role in ensuring the transfer adheres well and looks professional on different substrates, especially for larger applications where quality is paramount.

What are some common challenges faced with DTF transfers for different sizes?

Common challenges when working with DTF transfers across different sizes include pixelation from resizing intricate designs and the potential for ghosting during application. To mitigate these issues, it is crucial to experiment with sizing, calibrate your printer properly, and adjust application settings according to the materials used.

How are current trends influencing DTF printing in custom apparel?

Current trends in DTF printing reflect an increasing demand for diverse materials and garment sizes, leading to innovations such as dual-layer prints for complex designs. As the market evolves, manufacturers are also developing eco-friendly inks and films suitable for both small and large-scale DTF transfers, allowing for sustainable custom apparel printing solutions.

| Key Point | Explanation |

|---|---|

| Understanding DTF Transfer Sizes | DTF transfers can be customized to any garment size, from small logos to large graphics. Proper resizing is critical for maintaining quality. |

| Machine Calibration | Proper calibration of DTF printers is essential for each size transfer. Automatic adjustments help, but understanding mechanics is beneficial. |

| Material Compatibility | Choosing the right film and adhesive is vital, especially for large prints. High-quality films prevent pixelation and ensure vibrant colors. |

| Market Trends and Innovations | The demand for custom apparel drives trends in DTF printing, leading to new films for both small and large applications. |

| Technical Challenges | Larger DTF designs face technical issues like ghosting. Proper printer settings can mitigate this and enhance overall results. |

| Future Directions | Sustainability trends are leading to eco-friendly DTF inks and films, making it easier to print large designs without quality loss. |

Summary

DTF transfers have revolutionized the world of custom apparel by allowing for diverse and vibrant designs across various sizes. The key to successful DTF printing lies in understanding how to size transfers effectively, calibrating printing machines accurately, selecting compatible materials, and being aware of current market trends. Whether your project entails small logos or large graphics, properly managing these elements ensures that your custom creations stand out in a competitive market. Furthermore, as the industry evolves towards more sustainable practices, staying informed will empower you to produce high-quality prints that meet both aesthetic and environmental standards.