DTF transfers, short for Direct-to-Film transfers, have taken the DIY t-shirt printing world by storm, offering a modern solution for creating custom apparel. This innovative printing method allows enthusiasts and small businesses to achieve vibrant, high-quality designs with ease, eliminating the steep learning curve associated with traditional printing techniques. With DTF transfers, you can print intricate graphics and detailed images directly onto a special film, making your t-shirt designs come to life. This post will delve into the reasons why DTF has become the go-to choice among crafters, highlighting its simplicity, cost-effectiveness, and impressive durability. If you’re considering entering the world of T-shirt design, understanding DTF transfers could be your first step toward transforming your ideas into stunning wearable art.

In the realm of custom apparel creation, Direct-to-Film printing (DTF) provides an exciting alternative for those interested in DIY fabric decoration. This technology merges the advantages of traditional printing methods with modern advancements, allowing users to produce intricate and colorful designs on various fabrics. By utilizing a film transfer process, creators can achieve professional-quality prints without the need for extensive setups, making it ideal for both hobbyists and small enterprises. As we explore this innovative approach to T-shirt design, we will uncover how DTF printing not only streamlines the production process but also enhances the overall quality and longevity of printed garments.

Understanding the Basics of DIY T-Shirt Printing

DIY t-shirt printing captivates the creative minds of individuals eager to express their unique styles through custom apparel. The diverse range of available printing methods includes traditional screen printing, Direct-to-Garment (DTG) printing, and now, Direct-to-Film (DTF) transfers. Knowing each method’s pros and cons is essential for selecting the best approach that aligns with one’s skill level and business goals. DIY enthusiasts often find themselves navigating these options, weighing the quality, costs, and techniques required for making t-shirt printing a rewarding venture.

Understanding the basics of DIY t-shirt printing allows creators to make informed decisions about their projects. For instance, screen printing offers vibrant results but can require extensive setup and materials, making it less accessible for beginners. Conversely, DTF transfer technology streamlines the printing process while delivering high-quality results. This method empowers even novices to produce professional-grade designs without the steep learning curve associated with other printing techniques.

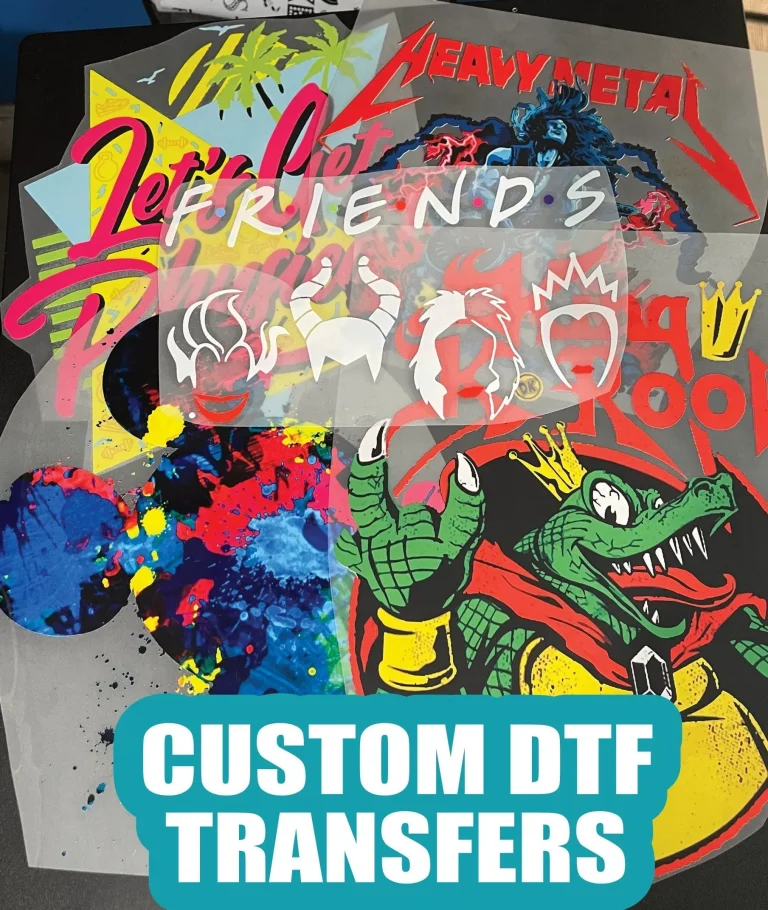

The Advantages of DTF Transfers in Custom Apparel

DTF transfers have quickly become a favorite in the realm of custom apparel due to their numerous advantages. One significant benefit is their capacity to produce vibrant, intricate designs. Unlike traditional methods that may struggle with fine details or gradients, DTF printing excels, allowing users to create eye-catching graphics that can distinguish their t-shirts in a competitive market. Furthermore, this method provides a level of flexibility that appeals to many creators, enabling them to experiment with diverse patterns and colors in their designs.

Another advantage that sets DTF transfers apart is their cost-effectiveness, especially for small batches of apparel. Since the setup costs are lower compared to screen printing, hobbyists and small business owners can invest in quality prints without going over budget. Additionally, the durability of DTF transfers ensures that these designs can withstand multiple washes, retaining their clarity and vibrancy over time. Such longevity reinforces customer trust and satisfaction, leading to repeat business and referrals in the highly competitive custom apparel landscape.

Exploring the DTF Printing Process

Understanding the DTF printing process is crucial for anyone interested in DIY t-shirt printing. This innovative technique simplifies traditional printing methods by transforming complex steps into a straightforward approach. The process begins with creating a digital design that resonates with the intended audience, followed by printing the design onto specialized DTF film. After applying adhesive powder to the printed design, heat pressing the film onto fabric further enhances the durability of the final product.

An essential aspect of the DTF printing workflow involves the heat pressing stage, which effectively bonds the printed design with the fabric. This step requires attention to temperature and pressure to achieve optimal results. Once the pressing is complete, removing the film reveals a stunning, vibrant design ready to wear. By mastering the DTF printing process, individuals can unlock endless possibilities for creative expression and small business success in the world of custom apparel.

Key Factors Driving the Popularity of DTF Transfers

The rising popularity of DTF transfers can be attributed to several key factors that resonate well with modern consumers and entrepreneurs alike. One major driving force is the ease of use associated with this printing method. DTF transfers require minimal setup compared to classic screen printing techniques, making them an excellent choice for beginners and those who may not have extensive experience in DIY t-shirt printing. The straightforward nature of the process often leads to quicker turnaround times, making it ideal for those looking to capitalize on current trends.

Additionally, advancements in technology play a vital role in boosting the attractiveness of DTF transfers. Continuous improvements in ink formulations and printer capabilities have elevated the quality of prints produced, allowing for more vivid colors and sharper details. As a result, the DTF printing method is gaining traction among professional printers and hobbyists, both of whom appreciate its versatility and ability to meet diverse printing demands.

The Business Potential of DTF Transfers

Choosing DTF transfers as a primary method for t-shirt printing opens up a realm of business opportunities for those passionate about custom apparel. Entrepreneurs can leverage the ease of producing high-quality prints to cater to niche markets or create personalized products. The cost-effectiveness of DTF transfers enables businesses to offer competitive pricing while maintaining a healthy profit margin, particularly for smaller runs of unique designs that appeal to specific customer bases.

Moreover, the ability of DTF printing to consistently produce durable, long-lasting garments enhances customer satisfaction. As word spreads about the quality and affordability of products created through DTF transfers, businesses can establish a loyal customer base, further fueling expansion opportunities. This combination of creativity, accessibility, and potential for profitability is making DTF transfers a favored choice among small businesses and DIY t-shirt printing enthusiasts.

The Future of DTF Printing Technology

Looking ahead, the future of DTF printing technology appears bright, reflecting both ongoing advancements in the industry and the growing demand for high-quality custom apparel. As manufacturers continue to innovate by introducing improved printing techniques and sustainable practices, the DTF method is poised to dominate the DIY t-shirt printing landscape. This evolution is driven by increasing consumer preference for environmentally-friendly products, encouraging printers to adopt eco-conscious materials and processes.

Another factor contributing to the promising future of DTF transfers is the expanding community of creators and entrepreneurs eager to experiment with this technology. With more individuals recognizing the potential of DTF printing for transforming their designs into tangible products, the creativity flowing from this field is bound to yield exciting innovations and diverse styles. As more people embrace the DTF method, it will likely lead to collaborations, shared knowledge, and a vibrant marketplace for custom apparel.

Frequently Asked Questions

What are DTF Transfers and how do they work in DIY T-shirt printing?

DTF Transfers, or Direct-to-Film printing, are a modern method used in DIY t-shirt printing. This technique involves printing your designs onto a specialized film, applying an adhesive powder, and then heat-pressing the film onto the garment. This process allows for vibrant colors and intricate designs, making it a popular choice for creating custom apparel.

Why should I choose DTF Transfers over other printing methods for custom T-shirt design?

Choosing DTF Transfers for custom t-shirt design offers several advantages over other printing methods. DTF is known for its ease of use, high-quality prints with vibrant colors, cost-effectiveness for small runs, and durability that maintains print quality after multiple washes. These features make DTF a preferred choice for both DIY enthusiasts and small businesses.

Can I use DTF Transfers for dark-colored fabrics in my T-shirt printing projects?

Yes, DTF Transfers are highly effective on dark-colored fabrics. Unlike some other printing methods that struggle with darker backgrounds, DTF printing allows for bright prints that pop against any color, making it an excellent choice for custom apparel on dark materials.

What equipment do I need to get started with DTF Transfers for DIY t-shirt printing?

To begin using DTF Transfers for DIY t-shirt printing, you’ll need a DTF printer, heat press, DTF film, and adhesive powder. This equipment setup allows you to create high-quality custom T-shirt designs easily and efficiently, catering to both hobbyists and entrepreneurs.

Are DTF Transfers environmentally friendly compared to traditional printing methods?

DTF Transfers are considered more environmentally friendly than traditional printing methods like screen printing. The DTF process typically uses fewer materials and generates less waste. Additionally, many DTF inks are now eco-friendly, allowing you to create custom apparel while minimizing your ecological footprint.

How do I ensure the longevity of my prints when using DTF Transfers on custom apparel?

To ensure the longevity of prints made with DTF Transfers, it’s essential to follow proper washing and care instructions. Wash garments inside out in cold water and avoid high heat drying to prevent fading or damage. When cared for properly, DTF prints can withstand multiple washes while maintaining their quality and vibrancy.

| Key Benefits of DTF Transfers | Description |

|---|---|

| Ease of Use | DTF transfers simplify the printing process, allowing for full-color designs to be applied in one go. |

| Quality and Vibrancy | DTF produces vibrant colors and intricate details, outperforming traditional printing methods. |

| Cost-Effectiveness | Lower barrier to entry, making it suitable for hobbyists and small businesses with limited budgets. |

| Durability | DTF prints are resistant to fading and cracking, ensuring long-lasting quality. |

| Technological Advancements | Ongoing improvements in technology lead to higher print quality and faster production. |

| Sustainability | Requires fewer materials and often utilizes eco-friendly inks. |

Summary

DTF Transfers have become the go-to choice for DIY t-shirt printing due to their ease of use, impressive quality, and cost-effectiveness. As more enthusiasts and businesses discover the benefits of Direct-to-Film printing, they are empowered to create stunning custom apparel with durability and professional results. This innovative method not only simplifies the printing process but also supports sustainability efforts, making it a versatile solution for anyone looking to express their style through custom t-shirts.