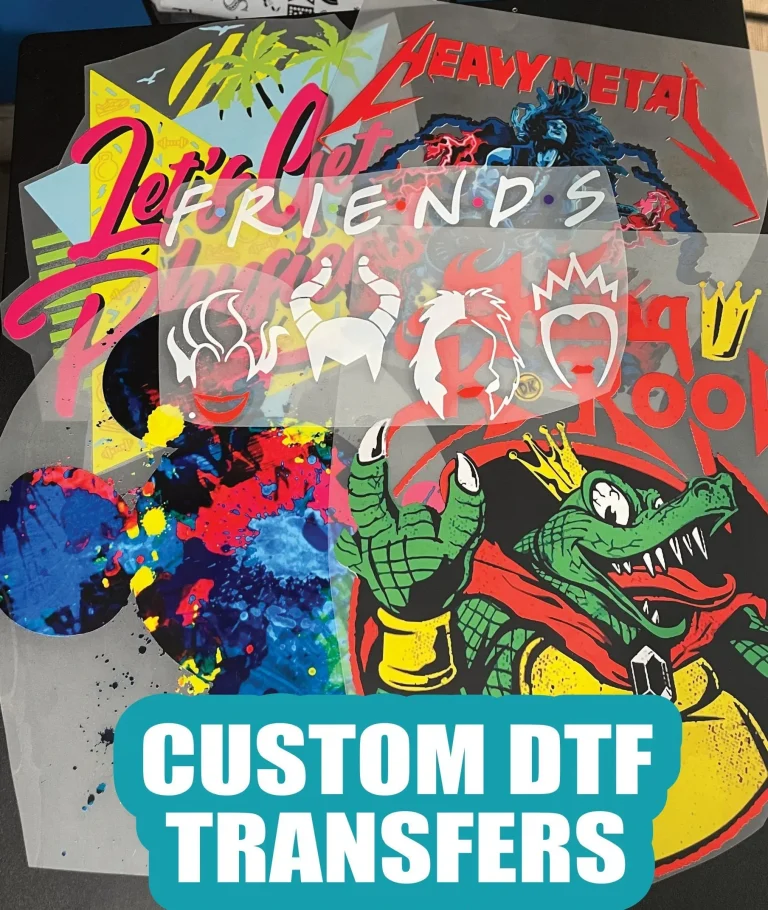

In the world of custom apparel, DTF transfers have emerged as a revolutionary method, reshaping the standards for fabric printing. Direct-to-Film (DTF) transfers provide an exceptional opportunity to create vibrant, high-quality designs that adhere seamlessly to various textiles. This innovative printing technology not only ensures durability but also imparts a soft finish that enhances the overall feel of the garment. For both seasoned professionals and enthusiastic hobbyists, mastering the nuances of DTF transfers is essential to achieving design success. In this article, we’ll delve into best practices for DTF, touching on design tips, material choices, and the latest trends in sustainable DTF printing.

Also known as Direct-to-Film printing, this technique offers versatility and precision, allowing designers to explore complex artwork without the limitations often found in traditional methods. By employing DTF technology, brands can effectively print intricate details and stunning gradients, appealing to a broader market. As we venture further into the dynamics of DTF processes, we will highlight essential strategies such as effective DTF design tips and optimal practices that ensure top-notch results. With sustainability at the forefront, understanding the implications of eco-friendly DTF practices will also be a critical topic as we navigate through the best strategies in this transformative printing industry.

The Evolution of DTF Printing Technology

Direct-to-Film (DTF) printing represents a significant technological advancement in the garment printing industry. Unlike traditional methods that often involve complex processes and limitations on fabric types, DTF offers flexibility and creativity to designers and printers alike. The advent of this technology allows artists to explore vibrant color palettes and intricate designs without worrying about the constraints typically associated with screen printing or heat transfer vinyl (HTV). As such, DTF has become a preferred choice for many businesses seeking to push the boundaries of their creative expression.

Moreover, DTF printing technology continues to evolve with the introduction of high-performance printers that enhance efficiency while maintaining print quality. New advancements also involve more durable transfer films that improve adhesion and longevity, which greatly benefits the overall printing process. This ongoing technology improvement translates to a more robust market presence for DTF, as it adapts to meet the increasing demands of both consumers and creative designers.

Essential DTF Design Tips for Maximum Impact

When creating designs specifically for DTF transfers, it is crucial to focus on resolution and detail. Employing high-resolution images—optimally at 300 DPI—ensures that your designs maintain visual integrity once printed. Print quality can significantly deteriorate if low-resolution files are used, resulting in blurry designs that fail to capture the attention of potential customers. Using sharply defined images allows the uniqueness and complexity of your artwork to shine through on the chosen fabric.

Color also plays a pivotal role in the success of your DTF designs. It is recommended to utilize the CMYK color space for design preparation, as this color model aligns with industry standards for printing. Conducting test prints is a best practice that can aid in determining the final appearance of colors on fabric. This approach helps you avoid unpleasant surprises during production, confirming that the vibrant hues and details you envisioned are translated accurately onto the garments.

Choosing Premium Materials for DTF Transfers

The selection of materials is a decisive factor for the successful application of DTF transfers. It is essential to choose high-quality transfer films specifically designed for this printing method, as inferior alternatives might lead to issues like peeling or fading over time. Investing in renowned brands ensures that your final products withstand the rigors of everyday wear, thereby strengthening consumer trust and satisfaction.

In addition to films, the right adhesive powder is crucial. Consistent application of adhesive across the transfer is necessary to achieve optimal durability, as uneven application can jeopardize the print’s longevity. Furthermore, utilizing high-standard inks aligns with the premium nature of your DTF projects, assuring that what’s printed remains vibrant and intact after multiple washes, reflecting the quality commitment of your brand.

Layering Techniques for Enhanced Visual Appeal

Utilizing layering techniques effectively in DTF designs can significantly elevate the visual appeal of the final garment. By combining various textures and colors through multiple layers, designers can create depth and dimension, drawing the eye to the intricacies of the design. This approach allows for greater creativity, enabling print shops to differentiate their offerings in a saturated market.

Moreover, careful consideration of layering can enhance the tactile experience of the printed fabric. Soft, high-quality layers ensure that the printed areas maintain comfort while maximizing visual intrigue. Implementing strategic layering not only enriches the aesthetic of the DTF transfer but also boosts consumer satisfaction, as wearers appreciate both the look and feel of their apparel.

Sustainable Practices in DTF Printing

As environmental consciousness rises, integrating sustainable practices into DTF printing processes is becoming increasingly important. Employing eco-friendly inks and materials not only supports environmental integrity but also resonates with today’s conscious consumers. Brands that prioritize sustainability are often more appealing to customers, paving the way for customer loyalty and positive word-of-mouth.

Incorporating sustainable practices does not mean sacrificing quality. In fact, many sustainable ink options today offer vibrant colors and strong adhesion comparable to their traditional counterparts. By adopting environmentally friendly practices, businesses can contribute to reducing the ecological footprint associated with garment production, demonstrating a commitment to both quality and responsibility.

Keeping Up with Market Trends in DTF Printing

The DTF printing landscape is dynamic and constantly changing, making it crucial for businesses to remain informed about the latest market trends. This includes understanding advancements in technology, which are essential for maintaining competitiveness. By following industry leaders, watching for emerging trends, and embracing changes such as upgraded printers and innovative transfer films, print shops can enhance their operational efficiency and product offerings.

Additionally, staying abreast of shifts in consumer preferences and demands allows businesses to tailor their DTF designs accordingly. Whether incorporating trending design elements or utilizing sustainable materials, adapting to market trends ensures that brands remain relevant. Engaging with industry publications, attending trade shows, and having an active presence in online communities can provide vital insights into how the DTF printing market is evolving.

Frequently Asked Questions

What are DTF transfers and how do they work in apparel printing?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a specialized transfer film which is then heat-pressed onto garments. This innovative printing technology allows for vibrant, durable, and soft designs, enabling intricate details that traditional methods may struggle with. DTF is versatile across various textiles, making it a popular choice in the printing industry.

What are the best practices for DTF design to ensure optimal print quality?

To achieve the best results with DTF transfers, create designs in high resolution (at least 300 DPI), use the CMYK color space to match printed colors accurately, and save files in formats like PNG or TIFF that support transparency. Additionally, always test prints before full production to catch any issues early.

How can I choose the right materials for effective DTF printing?

Selecting high-quality materials is crucial for DTF transfers. Use specialized transfer films designed for DTF applications, ensure even application of adhesive powder, and invest in compatible, high-quality inks to ensure vibrant and durable prints.

What are some DTF design tips to enhance the visual interest of my prints?

Utilize layering techniques to add depth and texture to your DTF designs. Integrating different elements and textures helps create visually compelling prints. Always remember to maintain high resolution and clear details to support these design techniques.

How is sustainability being integrated into DTF printing processes?

Sustainable DTF printing practices involve using eco-friendly inks and materials to cater to the growing demand for environmentally responsible fashion. Adopting these practices can enhance your brand image and align your business with consumer preferences toward sustainability.

What technological advancements are influencing the DTF printing industry?

Recent advancements in DTF printing technology have introduced high-performance printers and improved transfer films, allowing for faster printing processes without sacrificing quality. Staying updated with these innovations is essential for maintaining competitiveness in the evolving DTF market.

| Key Aspect | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs on a specialized film and using heat to apply them to garments, offering versatility and quality for intricate designs. |

| Best Practices for Design | 1. **Resolution and Detail**: Use high resolution (300 DPI) images. 2. **Color Space**: Utilize CMYK for accurate print colors. 3. **File Format**: Save as PNG or TIFF for transparency. 4. **Test Prints**: Always run samples before final production. 5. **Layering Techniques**: Incorporate layers for visual depth. |

| Choosing the Right Materials | – **Transfer Films**: Use high-quality films to avoid peeling. – **Adhesive Powder**: Ensure even application for durability. – **Inks**: Invest in compatible, high-quality inks. |

| Market Trends and Tools | – **Technology Upgrades**: Stay updated with new printers and materials. – **Design Software**: Use tools like Adobe Illustrator for better design preparation. – **Sustainable Practices**: Adopt eco-friendly materials to appeal to conscious consumers. |

| Environmental Considerations | Use sustainable inks and materials to meet consumer demand and enhance brand image. |

| Conclusion | To achieve design success in DTF transfers, it is crucial to embrace best practices, understand material selection, and keep pace with industry advancements. |

Summary

DTF transfers represent a cutting-edge solution in apparel printing, combining vibrant designs with flexibility in application. By following best practices, such as using high-resolution images and selecting the right materials, designers and print shops can achieve remarkable results. It’s essential to stay updated with market trends and technology to ensure a competitive edge. Emphasizing sustainability in practices not only aligns with contemporary consumer values but also enhances the brand’s reputation. As the DTF printing landscape evolves, continued learning and adaptation are key drivers of success in this dynamic industry.