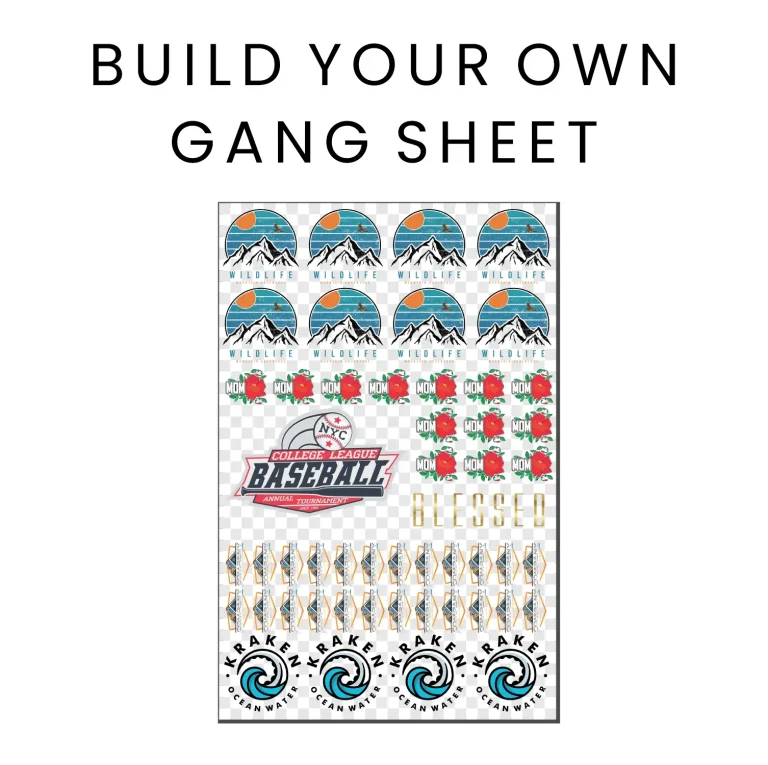

The DTF gangsheet builder is transforming the realm of garment decoration through Direct-to-Film (DTF) printing, offering an innovative solution that maximizes creativity while minimizing waste. This versatile tool allows users to print multiple designs on a single sheet, optimizing resources and ensuring vibrant colors and durability. For both novices and professionals, mastering gangsheet printing is a game changer, providing an efficient way to enhance fabric decoration without compromising quality. In this tutorial, we will cover everything from initial DTF setup to advanced techniques, empowering you to create stunning custom designs. Join us as we delve into the world of DTF printing and unlock the full potential of your creative vision with expert insights.

In the exciting field of fabric printing, utilizing a DTF sheet generator can streamline your design processes and elevate your print quality. Often referred to as Direct-to-Film printing, this method enables artists and businesses to produce vibrant, intricate designs efficiently. By combining multiple artworks on a single transfer film, known as a gangsheet, users can significantly decrease material waste while achieving greater color accuracy than traditional methods. This guide will explore essential steps in setting up your DTF printer and developing advanced printing techniques. If you’re looking to refine your skills and incorporate sophisticated design strategies, this DTF tutorial is essential for your journey.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a revolutionary technique that allows for vibrant, high-quality prints on fabric. It involves printing designs onto a special film which is then transferred to the substrate using a heat press. This process is advantageous over traditional methods like screen printing, largely because of its efficiency and versatility. DTF printing is particularly favored for its ability to reproduce intricate designs and vivid colors, offering endless creative possibilities for garment decoration.

Moreover, one of the standout features of DTF printing is its use of gangsheet printing. By combining multiple designs onto a single film sheet, users can minimize waste while maximizing the use of materials, making it an economically appealing choice for both large-scale production and personalized projects. This technique ensures that creative endeavors are achievable without incurring high costs, which is particularly beneficial for small businesses and individual creators.

The Essential Guide to DTF Setup

Setting up your DTF printing system is a crucial step that can significantly impact the quality of your prints. An optimal setup begins with selecting the right printer; printers equipped with pigment inks specifically designed for DTF applications are essential for achieving the best results. Make sure to calibrate your printer accurately to adjust the ink density, ensuring compatibility with the transfer films used. An improper setup at this foundation can lead to issues ranging from inadequate color vibrancy to misalignment during the transfer process.

In addition to hardware considerations, adequate software choices are equally important for a successful DTF setup. Utilizing design software that supports high-resolution graphics, such as Adobe Illustrator or CorelDRAW, will enhance your ability to create intricate designs. This software will allow you to manage layers effectively, ensuring that designs fit seamlessly on the gangsheet without wasted space. Therefore, ensuring both hardware and software are properly configured lays the foundation for exceptional DTF printing results.

Creating Stunning Designs for DTF Gangsheet Printing

Designing for a DTF gangsheet involves strategic planning and creativity. High-resolution graphics in formats like PNG or TIFF are essential to maintain clarity and detail in the final product. Additionally, consideration of color layering is pivotal; understanding how to integrate white ink channels effectively can significantly improve the final print quality, particularly for designs with contrasting colors. Successful designs not only focus on aesthetics but also on optimizing space on gangsheet to produce as many prints as possible without sacrificing quality.

Layer management is another critical aspect when creating designs for DTF printing. Each design on the gangsheet must be strategically placed to avoid overlaps and maximize the use of the transfer film. This means paying attention to details like spacing and alignment, which will help in maintaining an efficient workflow. The ability to arrange multiple designs efficiently can not only save material costs but also allow for faster production times, giving artists and businesses a competitive edge.

Optimizing the DTF Printing Process for Success

The printing process for DTF gangsheet printing involves a series of precise steps that must be followed to achieve optimal results. After printing the designs onto the transfer film with your DTF printer, the next critical step is applying adhesive powder while the ink is still wet. This powder helps the ink bond with the fabric during the transfer process. Curing the printed film is essential as it solidifies the adhesive, making it ready for transfer, and ensuring long-lasting prints that withstand washing and wear.

Temperature and pressure settings during the heat press stage can vary depending on the type of fabric being used. It’s vital to experiment and find the right balance to prevent issues such as under-exposure or damage to the film. Engaging with the larger DTF community through online forums or tutorials can provide additional insights into troubleshooting these settings, helping both new and experienced users refine their printing process for better outcomes.

Common DTF Printing Problems and Solutions

Like any printing method, DTF gangsheet printing may come with its fair share of challenges. Common issues include ink clogging, which can be mitigated by regular printer maintenance and consistent cleaning of print heads. Additionally, misaligned prints can lead to wasted materials and unsatisfactory results, making it essential to double-check alignment settings before starting each new gangsheet. These proactive steps are vital for anyone aiming to produce high-quality prints consistently.

Temperature-related challenges can also arise during the transfer process. If the temperature is too high, it might burn the film; conversely, too low a temperature might result in incomplete transfers. Understanding the specific requirements of various fabric types can significantly enhance your print quality. Seeking guidance from experienced users or exploring external learning resources can provide invaluable tips for overcoming these hurdles, facilitating a smoother printing experience and better outcomes.

Exploring Advanced DTF Techniques for Professionals

For those looking to advance their DTF gangsheet printing skills, delving into advanced techniques can set you apart from the competition. Color layering, for example, allows you to create complex prints that showcase unique aesthetics, adding depth and dynamism to your designs. Experimenting with textures can also create a visually striking appearance, offering a tactile quality that can enhance the overall appeal of your garments.

Another innovative approach is the use of unique inks, such as glow-in-the-dark or metallic options. These specialized inks not only enhance the visual impact but also open new avenues for creativity in design. Staying on top of industry trends and continuously experimenting with new techniques will help keep your work fresh and exciting, ensuring you can cater to diverse market demands while also challenging your creative boundaries.

Frequently Asked Questions

What is a DTF gangsheet builder and how does it work in DTF printing?

A DTF gangsheet builder is a tool or software that allows users to create multi-design print sheets for DTF printing. It optimizes material usage by enabling the arrangement of multiple graphics on a single sheet, minimizing waste and maximizing efficiency. This approach is ideal for businesses and hobbyists looking to produce high-quality designs with vibrant colors for garment decoration.

What are the key advantages of using DTF gangsheet printing over traditional methods?

DTF gangsheet printing offers several advantages over traditional printing methods like screen printing. It provides better color vibrancy, faster production times, and the ability to print multiple designs on one sheet. This method reduces material waste and allows for greater creativity in garment decoration, making it a preferred choice among professional printers.

How do I set up my DTF printer for effective gangsheet printing?

To set up your DTF printer for efficient gangsheet printing, invest in a printer designed for DTF printing that uses pigment inks. Calibrate the printer settings such as ink density and ensure compatibility with the transfer film. Regular maintenance, including cleaning print heads and checking alignments, is also essential for optimal performance during the printing process.

What software is recommended for designing DTF gang sheets?

For creating designs for DTF gang sheets, software such as Adobe Illustrator and CorelDRAW are widely recommended. These programs support high-resolution graphics and offer tools for managing layers and optimizing design placement, which are crucial for maximizing the gangsheet layout and ensuring effective printing outcomes.

What common challenges might I face when using the DTF gangsheet builder, and how can I troubleshoot them?

Common challenges include ink clogging, misalignment of designs, and temperature issues during transfers. To troubleshoot these, regularly clean the printer’s print heads, check alignment settings before printing, and carefully monitor temperature settings during the heat press process to ensure complete and accurate transfers.

Are there advanced DTF techniques I can explore after mastering the basics of gangsheet printing?

Yes, after mastering the basics of DTF gangsheet printing, you can explore advanced techniques such as color layering, incorporating texture effects, and experimenting with unique inks like glow-in-the-dark or metallic options. These techniques can enhance your designs and differentiate your prints in the competitive garment decoration market.

| Key Point | Description |

|---|---|

| Introduction to DTF Printing | DTF printing is transforming garment decoration by allowing vibrant, durable prints using a gangsheet. |

Summary

DTF gangsheet builder is an innovative tool that opens new avenues for creativity and efficiency in garment decoration. This tutorial not only introduces you to the fundamentals of DTF printing but also guides you step-by-step through setting up your printer, optimizing designs, and troubleshooting common issues. With an emphasis on resource maximization through gangsheet printing, users can benefit from an effective method to produce high-quality designs while reducing waste. As you delve deeper into the advanced techniques available in DTF printing, you’ll discover how to push creative boundaries and enhance your skill set. The DTF gangsheet builder empowers all users—whether beginners or seasoned pros—to expand their creative horizons and succeed in the dynamic world of digital printing.