In the ever-evolving realm of printing, UV DTF transfers stand out as a formidable advancement, bridging the gap between creativity and functionality. This innovative method harnesses the power of UV printing technology combined with Direct-to-Film (DTF) techniques to deliver exceptional results on a variety of surfaces. Businesses seeking to enhance their custom transfers can now achieve vibrant, durable prints that withstand the test of time. With a focus on print durability and versatility, the UV DTF transfer process opens new avenues for artistic expression and commercial success. Join us as we explore the intricate details of this remarkable printing solution, highlighting its benefits and best practices.

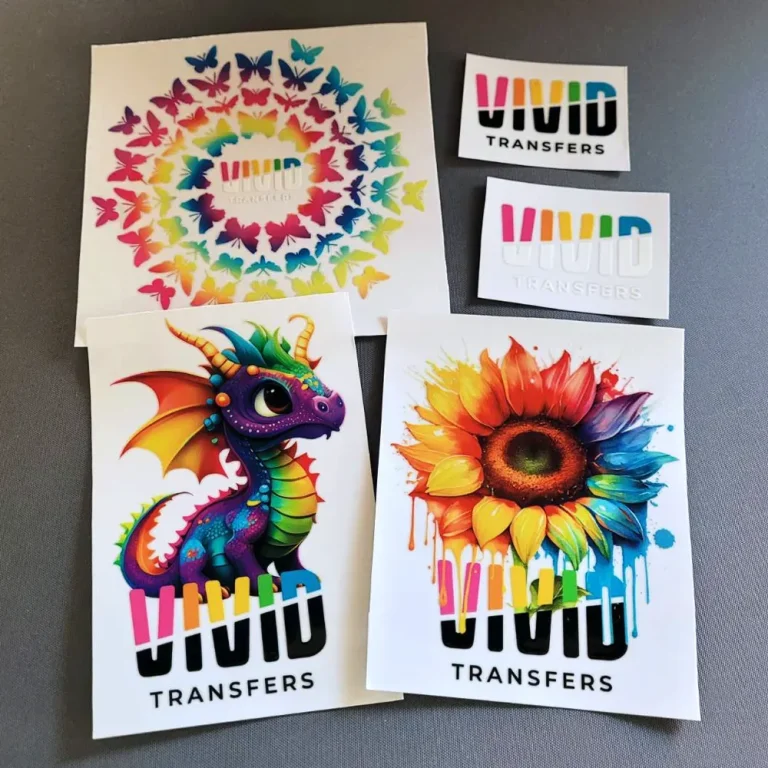

Introducing UV DTF transfers, a remarkable fusion of Direct-to-Film and ultraviolet printing technologies that revolutionize the way prints are created and applied. This state-of-the-art approach allows for unparalleled customization in print design, producing intricate designs that maintain their allure and resilience over time. The transfer process involved ensures that prints adhere effectively to diverse materials, providing a versatile solution for modern printing needs. By leveraging the unique properties of UV inks, this technique not only enhances visual appeal with rich colors but also delivers exceptional durability. As we delve deeper into the advantages offered by UV DTF printing, we’ll uncover the potential it holds for businesses and artists alike.

The Unique Process of UV DTF Transfers

UV DTF transfers are groundbreaking in the printing world, primarily due to their unique and systematic process. At the core of this method is the utilization of UV-curable inks which offer distinct advantages over traditional solvent inks. Initially, the design is prepared digitally, allowing for precise color and detail adjustments. This preparation phase requires specialized software that caters to various substrate specifications, ensuring that the final design aligns perfectly with its intended application.

Following design preparation, the printing begins. High-quality UV printers are employed to print the design onto a specialized transfer film. The significant aspect of using UV inks is that they require exposure to ultraviolet light to cure. This process not only results in vibrant and saturated colors but also enhances ink adhesion on different materials, which is essential for durability in the final product.

Benefits of Choosing UV DTF Transfers

The versatility of UV DTF transfers cannot be overstated. Unlike some conventional printing methods, UV DTF allows for high-quality printing on a plethora of surfaces, including textiles, ceramics, plastics, and even metal. This broad range of compatibility opens up diverse creative avenues for designers and manufacturers alike, making it easier to cater to specific customer needs without being limited to one material.

Another significant advantage of UV DTF transfers is their enhanced durability. Prints produced using UV inks are more resistant to scratching, fading, and general wear compared to their counterparts produced with traditional methods. The result is a product that not only meets aesthetic standards but also stands the test of time, ensuring customer satisfaction and repeat business.

Understanding the Transfer Process

The transfer process of UV DTF transfers is meticulously planned to ensure a successful final outcome. After the design has been printed onto the transfer film and cured using UV light, the next critical step is applying the transfer to the desired substrate. This application often involves utilizing a heat press that applies both heat and pressure, ensuring a strong bond between the film and the material for long-lasting results.

Once the transfer application is complete, additional finishing techniques may be employed to elevate the overall quality of the product. Options such as trimming the edges of the transfer or applying a protective coating can enhance both the aesthetic and functional aspects of the print, providing an extra layer of durability and visual appeal for a more professional finish.

Maximizing Print Durability with UV DTF Transfers

Print durability is a pressing concern in any custom transfer business, and UV DTF offers robust solutions. The unique properties of UV-curable inks mean that they create a chemical bond with the substrate upon curing. This superior adhesion not only helps in sustaining color vibrancy over time but also prepares the prints to withstand harsher conditions, making them ideal for products intended for outdoor or high-wear situations.

Moreover, businesses that prioritize the longevity of their prints should invest in quality materials, including high-grade transfer films and UV inks. Using top-tier components in the production process significantly enhances the overall durability of the transfer. Proper maintenance of printing equipment is also crucial; a clean printer results in clearer prints and fewer defects, further ensuring that the end product meets durability expectations.

Tips for Successful UV DTF Printing

To optimize the results with UV DTF transfers, it is essential to implement industry best practices. A key tip is to conduct substrate testing before a full production run. This preliminary step allows printers to gauge compatibility and make necessary adjustments to the transfer process, ensuring optimal results that align with customer demands. Testing can reveal how well a specific substrate handles UV inks and whether any preprocessing is required.

Another vital aspect is ensuring proper curing of the inks during the printing stage. Inadequate UV exposure can lead to prints that are tacky or prone to smudging, while over-curing could result in brittle prints that may crack easily. Therefore, adhering to precise curing times and intensity settings is critical to achieving high-quality, durable transfers.

The Future of UV DTF Transfers in Custom Printing

As technological advancements continue to emerge, the future of UV DTF transfers looks particularly bright. With increasing customer demand for customization across various industries, businesses that adopt UV DTF printing will be well-positioned to meet these challenges. Innovations in ink formulations and printing technologies are expected to further enhance the capabilities and results of UV DTF transfers, solidifying their place in custom printing.

Moreover, as sustainability becomes more of a priority in manufacturing, the eco-friendliness of UV inks—especially those with low VOC emissions—aligns perfectly with consumer expectations. Companies that leverage these aspects in their marketing strategies can attract environmentally conscious customers, thereby expanding their market reach. The evolution of UV DTF technologies holds exciting potential for those looking to push boundaries and lead in the custom printing landscape.

Frequently Asked Questions

What are UV DTF transfers and how are they made?

UV DTF transfers, or UV Direct-to-Film transfers, combine UV printing technology with the DTF printing process. The method involves printing digital designs onto a special transfer film using UV-curable inks. After printing, the design is cured with UV light, solidifying the inks, and enhancing durability. The film is then applied to various substrates using heat and pressure, allowing for vibrant, long-lasting prints.

What are the benefits of using UV DTF transfers over traditional printing methods?

UV DTF transfers offer several advantages compared to traditional printing methods. Firstly, they provide exceptional print durability, as UV inks resist fading and wear. Secondly, these transfers are versatile, allowing printing on a wide range of materials, including textiles and rigid surfaces. Additionally, UV DTF provides vibrant colors and eco-friendly options due to low VOC emissions in many UV inks.

How does the transfer process work for UV DTF printing?

The transfer process for UV DTF printing involves several steps: 1) Design preparation involves creating the artwork digitally. 2) The design is printed onto a special transfer film using UV inks. 3) After printing, the inks are cured using UV light, ensuring solid adhesion. 4) The cured film is then applied to the chosen substrate with a heat press, ensuring a strong bond. 5) Finally, finishing touches may be added to enhance the final product.

What materials can be used with UV DTF transfers?

UV DTF transfers are highly versatile and can be applied to a variety of materials. This includes textiles like cotton and polyester, as well as rigid surfaces such as plastics, ceramics, and even metal. This wide adaptability makes UV DTF transfers ideal for custom transfers across different product lines.

How important is print durability in UV DTF transfers?

Print durability is one of the key strengths of UV DTF transfers, as the use of UV-curable inks provides resistance to fading, scratching, and general wear. This ensures that products retain their quality over time, making UV DTF an excellent choice for items that undergo frequent use or are exposed to harsh conditions.

What tips can improve my success with UV DTF transfers?

To achieve optimal results with UV DTF transfers, always conduct substrate testing to confirm compatibility. Ensure proper curing of inks to maintain adhesion quality, and carry out regular maintenance on your printing equipment to prevent defects. Lastly, always use high-quality transfer films and inks to enhance overall print quality, ensuring vibrant and durable outcomes.

| Topic | Details |

|---|---|

| Process | 1. Design Preparation – Creating digital graphics that align with the substrate. 2. Printing – Using UV printers to print on transfer film with UV-curable inks. 3. Curing – UV light solidifies the inks for durability. 4. Transfer Application – Using a heat press to adhere the print to the substrate. 5. Finishing – Enhancing final product appearance. |

| Benefits | 1. Versatility – Can print on various materials. 2. Durability – Long-lasting prints resistant to wear. 3. Vibrant Colors – Rich color gamut for impactful visuals. 4. Eco-Friendly – Low in VOCs, appealing to sustainable practices. |

| Tips for Success | 1. Substrate Testing – Test transfers on sample materials before full runs. 2. Proper Curing – Ensure correct exposure to UV light for adhesion. 3. Equipment Maintenance – Regular cleaning and upkeep of machines. 4. Quality Materials – Use reputable transfer films and inks for best results. |

Summary

UV DTF Transfers represent a transformative advancement in the printing industry, skillfully merging innovative technology with the need for customizable solutions. This printing method enables creators and businesses to produce vibrant, durable prints on various substrates, which is essential in today’s competitive market. By comprehensively understanding the UV DTF transfer process, emphasizing its key benefits, and adhering to expert recommendations, users can effectively leverage this technology to meet diverse printing needs. As the landscape of printing continues to evolve, staying updated on UV DTF transfers will ensure that users remain at the forefront of the industry.