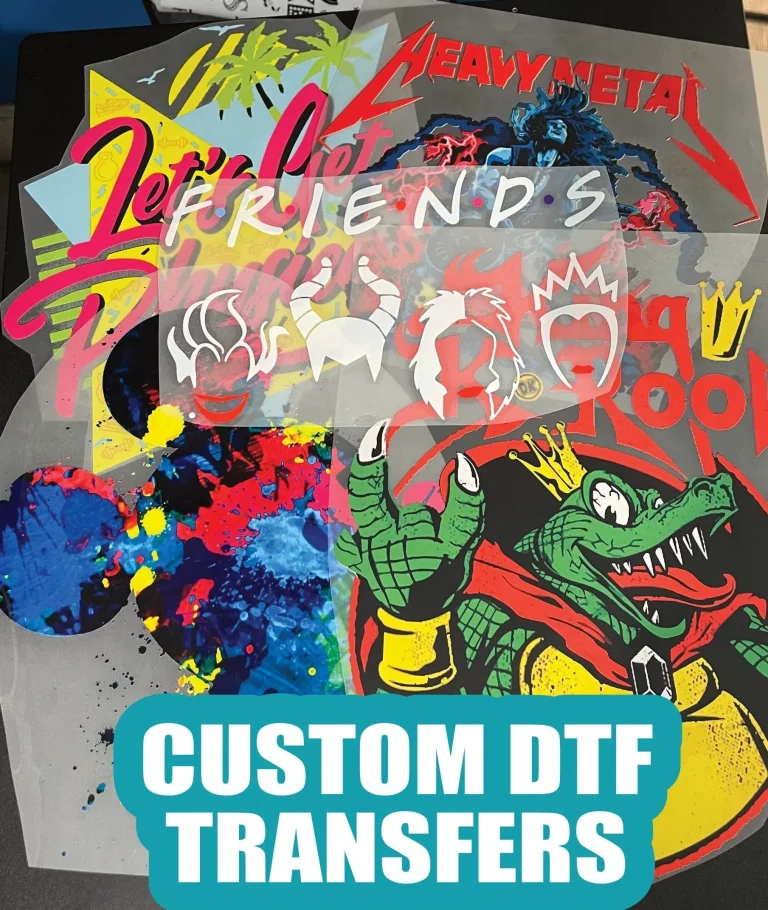

DTF Transfers, or Direct-to-Film transfers, are transforming the way we approach custom apparel printing, offering a vibrant and durable solution for designers and businesses alike. This versatile textile printing method allows intricate designs to be printed onto a specialized film, making it compatible with a wide range of fabrics. Whether you’re creating custom t-shirts, bags, or other textile items, the DTF printing process ensures high-quality results that stand out. The benefits of DTF transfers are numerous, including cost-effectiveness, ease of use, and the ability to produce stunning color-rich prints. In this guide, we will explore how you can maximize your design potential using DTF transfers through an easy-to-follow approach.

Direct-to-Film printing, often referred to simply as DTF, is a groundbreaking technique in the world of textile customization and apparel decoration. This innovative approach allows for the creation of vibrant prints on fabric by first transferring the design onto a film, which can be seamlessly applied using a heat press. As a versatile method of custom clothing production, DTF printing stands out due to its ability to produce detailed imagery and the wide range of materials it can be used on. Understanding the advantages of this printing technology not only enhances your design capabilities but also elevates the quality of your finished products. Join us as we uncover more about DTF transfers and their key role in revolutionizing custom apparel printing.

The Basics of Direct-to-Film (DTF) Transfers

Direct-to-Film (DTF) transfers represent a groundbreaking advancement in the field of textile printing. This innovative method utilizes a special film that allows intricate designs to be printed and subsequently heat applied to fabric surfaces. Unlike traditional printing methods like screen printing, DTF transfers boast enhanced color vibrancy and durability, making them an ideal choice for custom apparel enthusiasts. The process begins with printing the desired artwork onto a specialized film using DTF-compatible inks, which are engineered to produce stunning visual results.

One of the standout features of DTF transfers is their versatility, as they can be applied to a variety of materials including cotton, polyester, and blends. This flexibility opens up new opportunities for designers looking to create custom apparel, as it allows for the exploration of diverse fabric types and textures. Furthermore, the DTF printing process often yields higher-quality outputs with finer details and a broad color spectrum, attracting both amateur and professional designers alike.

Step-by-Step Guide to DTF Printing

To successfully execute a DTF printing project, it’s essential to follow a structured approach. This process begins with the preparation of high-resolution artwork, which ensures that the printed designs are sharp and vibrant. Utilizing design software such as Adobe Illustrator is recommended to create the best quality graphics. Saving images in PNG format with transparent backgrounds is crucial for clean edges and optimal detail reproduction, laying the groundwork for successful DTF transfers.

After the artwork is ready, the next step is the actual printing onto the DTF film. A specialized DTF printer uses water-based inks, which are known for their brightness and longevity. The key to achieving a successful print lies in selecting the right settings on the printer and maintaining a high resolution, as this directly impacts the final design quality on fabric. Following the printing, applying adhesive powder to the wet ink is a critical step that ensures the ink can properly adhere to the garment during the heat transfer process.

Advantages of DTF Transfers for Custom Apparel

DTF transfers bring a multitude of benefits for those engaged in custom apparel printing. One significant advantage is their cost-effectiveness, particularly for small batches. Unlike screen printing, which can be expensive due to setup costs and equipment, DTF transfers provide a more affordable option for businesses looking to produce limited runs or unique items without a steep investment. This makes DTF an appealing choice for startups in the custom printing market.

Moreover, the high print quality associated with DTF transfers enables designers to create intricate works of art that stand out. The combination of vibrant colors and detailed imagery ensures that end products are visually striking and durable, meeting customer expectations for quality. Since DTF technology allows for printing on various fabric types, from cotton to blends, it opens up new horizons for creativity and personalization in fashion.

The DTF Printing Process Explained

The DTF printing process is defined by a series of meticulous steps that lead to a high-quality transfer that can be applied to garments. It all starts with the printing of the desired design onto a specialized transfer film using DTF-compatible inks. These inks are formulated to work seamlessly with the heat setting process, providing exceptional durability and vivid color output. Following the printing, an adhesive powder is applied to the wet ink, which is crucial for ensuring a successful transfer to the fabric.

Once the film is prepared, the actual transfer takes place using a heat press machine. This step is where the magic happens; the combination of temperature and pressure activates the adhesive, allowing the design to bond effectively with the chosen fabric surface. The precision of temperature settings, which typically hover around 320°F, is vital. Correctly executed, this process culminates in a resilient print that can withstand numerous washes, enabling long-term satisfaction for customers.

Caring for DTF Printed Garments

Proper care for garments printed with DTF transfers is essential to maintain their vibrancy and longevity. Providing customers with detailed care instructions can help prolong the life of their printed apparel. Recommended practices include washing items in cold water, avoiding bleach, and opting for gentle cycles when laundering. These tips not only help to keep the prints intact but also sustain the fabric quality, ensuring a durable product that retains its appeal over time.

Additionally, encouraging customers to air-dry their printed garments instead of using heat-drying methods can further enhance the longevity of the design. Heat can degrade the adhesive bond over time, leading to potential peeling or fading. Educating customers on these simple but effective care methods enhances their overall satisfaction and helps to uphold your brand’s reputation for quality and reliability.

Innovations in DTF Transfer Technology

The landscape of DTF transfer technology is constantly evolving, with innovations driving the industry forward. Recent advancements have seen the introduction of improved ink formulations that promise greater flexibility and wash resistance. These new inks not only enhance the durability of printed designs but also expand the creative possibilities for artists and designers, allowing for even more intricate and high-quality custom prints.

In addition to ink improvements, user-friendly DTF printers have entered the market, designed with the small business owner in mind. These machines come with simplified operating procedures, enabling users who may not have extensive printing experience to successfully create professional-quality prints. The ongoing efforts towards eco-friendly options, such as biodegradable inks and less toxic adhesives, also reflect the industry’s commitment to sustainability, catering to a growing segment of environmentally conscious consumers.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film that can be applied to various fabric surfaces using heat. This printing process produces vibrant and durable prints, making it popular in custom apparel printing and versatile textile printing applications.

What are the benefits of using DTF transfers for custom apparel printing?

The benefits of DTF transfers include their versatility in printing on multiple fabric types, lower setup costs compared to screen printing, and the ability to achieve high print quality with rich colors and intricate designs. These features make DTF transfers an excellent choice for various custom apparel needs.

Can any fabric be used with DTF printing?

Yes, DTF printing is compatible with a wide range of fabrics, including cotton, polyester, and blends. This versatility is one of the main advantages of DTF transfers, as they can be used for diverse applications in custom apparel printing.

What equipment is needed for the DTF printing process?

To effectively use DTF transfers, you need a specialized DTF printer that uses water-based inks, heat press machines for transfer application, and heat-cured adhesive powder. This equipment ensures optimal quality for your printed designs.

How do I ensure the longevity of prints made with DTF transfers?

To prolong the life of DTF transfer prints, instruct customers to wash garments in cold water and avoid bleach. Additionally, proper heat curing after application can enhance durability, ensuring that designs remain vibrant even after multiple washes.

What recent developments have been made in DTF transfer technology?

Recent developments in DTF transfer technology include improved ink formulations for better wash durability, user-friendly DTF printers designed for ease of use, and eco-friendly options like biodegradable inks and less toxic adhesives, catering to the growing demand for sustainable products.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A printing process that uses a special film to apply designs on various fabrics using heat, providing high-quality prints. |

| Preparation of Artwork | Create high-resolution designs in software like Adobe Illustrator, ensuring images are in PNG format for crisp details. |

| Printing the Design | Use specialized DTF printers that utilize water-based inks to ensure vibrant, durable prints. |

| Applying the Adhesive | Apply adhesive powder to wet ink to ensure proper adhesion during heat transfer, followed by curing the film. |

| Transfer Process | Transfer the design onto fabric using a heat press at recommended temperature, ensuring good pressure for adherence. |

| Finishing Touches | Wait for cooling before peeling off the film, possibly applying curing sprays for durability. |

| Caring for Printed Designs | Educate customers about proper care methods to extend the lifespan of printed items, such as washing techniques. |

| Benefits of DTF Transfers | Versatility with fabric types, cost-effective for small batches, and high-quality prints with vivid colors. |

Summary

DTF transfers offer a groundbreaking method for individuals and businesses looking to maximize their design potential in the fabric printing industry. By embracing the advanced technologies of Direct-to-Film transfers, users can create vibrant, long-lasting prints on various materials, ensuring the quality and appeal of their custom creations. The process, from artwork preparation to the application of designs, emphasizes precision and adaptability, making it an excellent choice for both small and large operations. As the technology continues to evolve, incorporating user-friendly printers and eco-friendly options, DTF transfers not only enhance creative possibilities but also align with sustainable practices, catering to the needs of modern consumers.