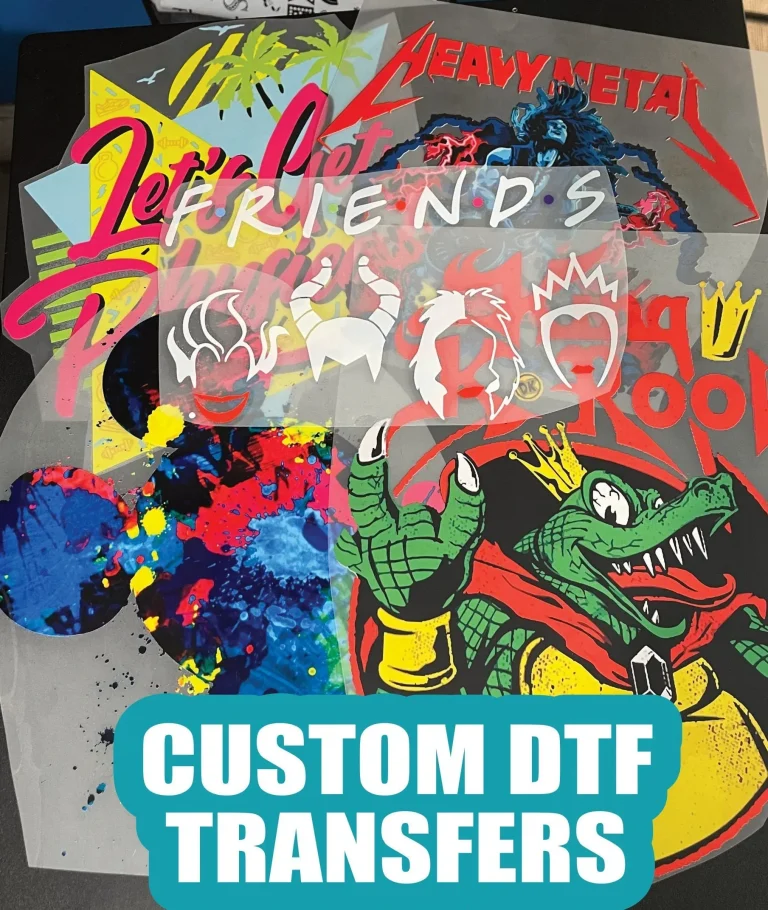

DTF transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel by offering vibrant prints that capture attention and elevate designs. This innovative printing technique uses specialized film to produce high-quality graphics on various fabric types, from cotton to polyester blends, allowing for unparalleled versatility. As the demand for personalization in clothing continues to grow, DTF transfers emerge as a go-to solution for those seeking striking and durable fabric prints. With DTF printing, designers can achieve intricate designs with rich colors and impressive detail, making it easier to stand out in a competitive market. In this comprehensive guide, we will explore the ins and outs of DTF transfers, from the printing process to the myriad benefits they offer for today’s custom apparel industry.

Also known as Direct-to-Film transfers, DTF transfers utilize a cutting-edge technique that streamlines the process of fabric printing while ensuring that prints remain bold and stunning. This method is becoming increasingly popular for crafting unique apparel designs, as it incorporates high-quality print technology to create detailed and colorful imagery on textiles. By leveraging the advantages of DTF printing, brands can achieve superior color accuracy and durability, enhancing the overall appeal of their products. Whether you’re in the market for custom t-shirts, hoodies, or other fabric items, this approach to fabric printing offers versatility that meets the needs of both small businesses and large enterprises. In the following sections, we will dive deeper into DTF transfers, illustrating their benefits, techniques, and how they can elevate your custom apparel.

Understanding DTF Transfers: The Future of Fabric Printing

DTF transfers, short for Direct-to-Film transfers, have quickly become a game-changer in the realm of custom apparel. This innovative fabric printing technique allows for high-definition designs to be transferred onto various textiles with impressive color accuracy and vibrancy. As businesses and DIY enthusiasts increasingly seek methods that showcase unique designs, DTF printing stands out due to its versatility across different materials, including cotton, polyester, and even blends. Unlike traditional printing methods, which can often limit the types of fabrics that can be used, DTF printing embraces a wide range, offering creative freedom and endless possibilities.

The process behind DTF transfers leverages advanced technology to ensure that colors remain vivid and eye-catching. Utilizing a special film, designs are printed with DTF inks known for their rich pigmentation. This method not only ensures that every detail of the design is captured but also protects the print during the transfer process, ultimately leading to long-lasting, high-quality results. As custom apparel continues to grow in popularity, understanding the mechanics and benefits of DTF transfers is essential for anyone looking to stand out in a saturated market.

The Step-by-Step Process of DTF Transfers

To fully appreciate the advantages of DTF transfers, one must grasp the intricate steps involved in their application. Firstly, the process begins with the creation of a digital design that perfectly encapsulates the vision of the creator. This design is then printed onto specialized film using a compatible inkjet printer outfitted with DTF inks. The quality of these inks is paramount; they contribute significantly to the overall vibrancy and detail of the printed design. The intricacy of this initial step sets the foundation for the entire printing process.

Following the design creation, the application of a hot-melt powder adhesive is crucial. This adhesive is spread onto the wet ink on the film, ensuring that the colors and designs adhere firmly to the fabric once applied. After that, the film undergoes heat curing, which activates the adhesive. This step is vital to maximizing the durability and longevity of the prints. When finally transferred onto the fabric using a heat press, the result is a stunning, vibrant print that is suitable for a myriad of applications, from casual wear to promotional items.

Benefits of Choosing DTF Transfers for Custom Apparel

One of the primary benefits of DTF transfers lies in their unparalleled versatility. They can be applied to a wide array of fabrics, making them an ideal choice for businesses that cater to diverse markets. Whether you are producing vibrant t-shirts, hoodies, or even accessories, DTF printing ensures that your designs maintain their integrity across different fabric types. This adaptability fosters creativity, allowing designers to experiment freely with textures and styles without worrying about compatibility issues.

Additionally, DTF transfers create prints that are not only eye-catching but also exceptionally durable. The prints resist fading and cracking, even after numerous washes, which is a crucial factor for consumers looking for quality products that stand the test of time. This durability translates to customer satisfaction, leading to repeat sales and a positive reputation in the market. With growing concerns about sustainability, many manufacturers are also exploring eco-friendly inks suitable for DTF printing, ensuring that businesses can meet demand while adhering to greener practices.

Recent Innovations Enhancing DTF Transfer Technology

The landscape of DTF transfers has evolved significantly due to recent technological advancements. New printers designed specifically for DTF processes have emerged, offering enhanced print speeds and efficiency. This has not only streamlined production workflows but also made DTF printing more accessible to small businesses and individual entrepreneurs. Equipped with the latest technology, these printers produce exceptional quality prints without the lengthy downtime often associated with older models.

Moreover, material innovations are continually enhancing the DTF transfer experience. Suppliers are developing specialized films and substrates that improve adhesion, print quality, and feel, making the end products even more desirable. With these advancements, custom apparel producers can now achieve results that were once thought to be achievable only through more traditional, resource-heavy printing methods. As the DTF market expands, staying informed about these innovations is crucial for any business aiming to leverage the benefits of this printing technique.

Key Considerations When Choosing DTF Transfers

While DTF transfers offer numerous advantages, there are important considerations to bear in mind before committing to this printing method. The quality of equipment plays a pivotal role in the outcome; investing in high-quality printers, heat presses, and consumables is essential for achieving professional-grade results. By using superior equipment, businesses can ensure that their prints will be vibrant and long-lasting, which is vital for maintaining customer satisfaction.

Additionally, evaluating the cost-effectiveness of DTF technology should be a priority when making business decisions. While the initial startup costs may be significant, the potential for high-quality production and longevity makes DTF printing an economically viable option in the long run. As custom apparel continues to thrive, businesses must assess their financial strategies, including production costs and pricing structures, to fully leverage the benefits of DTF transfers.

The Growing Popularity of DTF Printing Among Custom Apparel Creators

The rise of DTF printing is directly linked to an increasing demand for custom apparel solutions that are both high-quality and versatile. Many creators and small businesses have found DTF transfers to be a perfect fit for their needs, as they allow for vibrant prints on dark fabrics and complex designs that traditional methods may struggle with. As custom apparel becomes more mainstream, the ability to offer unique, high-quality garments through DTF printing can significantly distinguish a business in a competitive market.

Furthermore, the process of DTF printing is user-friendly, making it ideal for hobbyists and aspiring entrepreneurs. The straightforward steps involved in creating DTF transfers enable individuals with varying levels of experience to enter the custom apparel field confidently. With accessible resources and a wealth of information available, DTF printing presents an appealing opportunity for anyone interested in expressing their creativity through fashion.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film transfers, involve printing designs onto specialized film sheets that are subsequently applied to fabrics using heat and pressure. This method is ideal for creating vibrant prints on various fabric types, including cotton and polyester, allowing for high-quality custom apparel.

What advantages do DTF Transfers offer for custom apparel?

DTF Transfers provide numerous advantages, including versatility with different fabric types, vibrant color reproduction, and durable prints that resist fading and cracking. These benefits make DTF printing a preferred choice for many businesses in the custom apparel industry.

How does the DTF printing process differ from traditional printing methods?

The DTF printing process differs from traditional methods like screen printing by using a unique film transfer technology that allows for greater design precision and color vibrancy, making it suitable for small production runs and diverse fabric types.

Can DTF Transfers be used on all types of fabrics?

Yes, DTF Transfers are compatible with a wide range of fabrics including cotton, polyester, and blends. This versatility allows for vibrant prints on various materials, making DTF printing a desirable option for custom apparel production.

What factors should businesses consider before adopting DTF Transfer technology?

Businesses should consider the quality of printing equipment, the long-term cost-effectiveness of DTF Transfers, and the availability of eco-friendly materials and inks. These factors can influence the overall success and sustainability of adopting DTF printing.

Are DTF Transfers environmentally friendly?

While traditional DTF printing may utilize standard inks and adhesives, there is an increasing trend towards eco-friendly practices in the industry. Manufacturers are now exploring sustainable inks and processes, allowing DTF Transfers to appeal to environmentally conscious consumers.

| Key Points | Details |

|---|---|

| What are DTF Transfers? | A printing method using specialized film sheets for high-quality prints on various fabrics. |

| Process Overview | 1. Design Creation 2. Powder Adhesive Application 3. Heat Curing 4. Transfer to Fabric |

| Advantages of DTF Transfers | 1. Versatility 2. Vibrant Colors 3. Durability |

| Recent Developments | 1. Equipment Advancements 2. Increase in Popularity 3. Material Innovations |

| Considerations for Using DTF Transfers | 1. Quality of Equipment 2. Cost-Effectiveness 3. Environmental Considerations |

Summary

DTF transfers are becoming increasingly important in custom apparel printing, providing a method that combines vibrant color quality with flexibility in fabric choices. This printing technique has shown significant advancements and adoption in recent years, making it an essential option for anyone looking to produce high-quality custom garments. The unique advantages of DTF transfers, including durability and versatility, position it favorably against traditional printing methods, while continuous technological progress ensures it remains relevant and accessible to a growing audience.