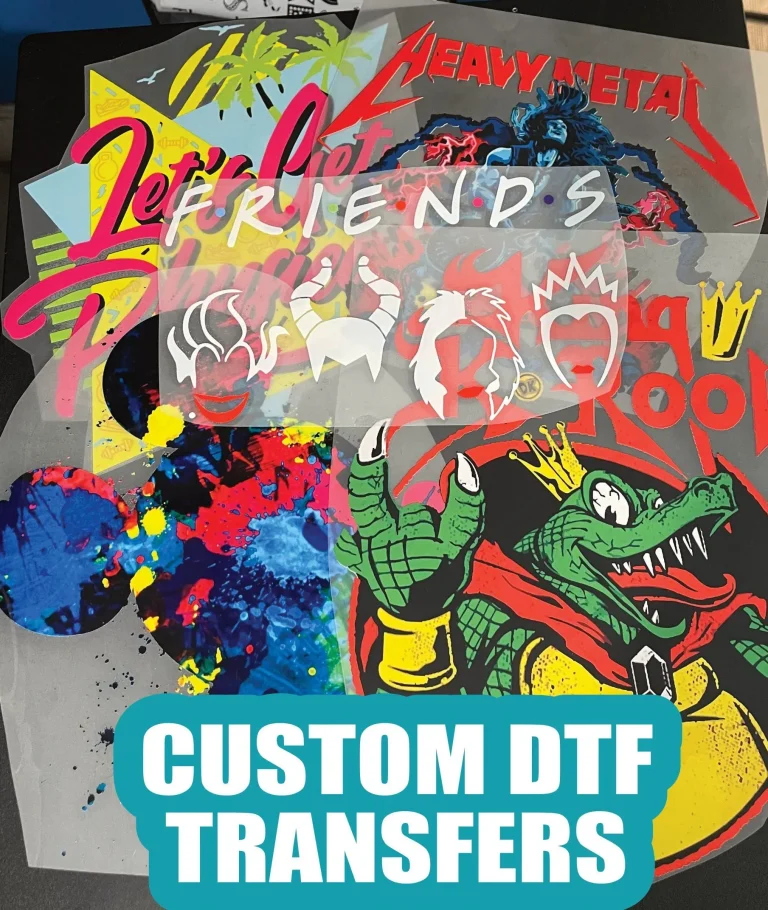

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel printing with their innovative approach to design application. By utilizing a special film to carry vibrant ink, DTF printing enables creators to achieve high-quality prints that can be easily transferred onto various fabric types. This method not only offers versatility in terms of fabric compatibility but also delivers durable and flexible designs that withstand the test of time. With a range of DTF transfer applications, from detailed logos to full-shirt prints, businesses and artists can bring their visions to life with stunning clarity. As we delve deeper into the realm of DTF transfers, you’ll discover how selecting the right DTF printing sizes can elevate your custom clothing projects, making them stand out in today’s competitive market.

The concept behind DTF printing, which involves direct transfer of designs from film to fabric, has rapidly gained popularity among producers of customized apparel. Known for its efficiency and versatility, direct film transfer technology provides a seamless solution for intricate designs and bold graphics alike. This methodology allows for a diverse range of applications, catering to various fabric types without compromising on quality. With notable advantages, such as the ability to produce eye-catching results at an economical rate, DTF technology is the go-to choice for independent designers and small businesses. Understanding the nuances of this printing technique will not only enhance your creative process but also optimize your product offerings in the ever-evolving fashion landscape.

What are DTF Transfers?

DTF transfers, or Direct-to-Film transfers, represent an advanced printing technique that is revolutionizing the custom apparel industry. Unlike traditional screen printing methods, DTF printing involves printing graphics onto a specialized film with high-quality ink, which is then heat pressed onto fabrics. This innovative technology allows creatives to achieve vibrant colors, intricate designs, and superb detail, leading to stunning outcomes for custom apparel and merchandise.

The layers of the DTF process begin with printing the design on a film and adding a powdered adhesive, which is crucial for a successful transfer. When heat is applied, the adhesive adheres to the fabric, ensuring that the design remains intact for a long time. Furthermore, DTF transfers work excellently on various materials, including cotton, polyester, and blended fabrics, making them an excellent choice for diverse applications ranging from promotional items to fashion wear.

Exploring DTF Printing Sizes

DTF printing sizes are incredibly versatile, allowing users to choose from a range of dimensions based on their specific project requirements. Small sizes such as 8×10 inches are perfect for intricate logos or small patches, making them ideal for accessories like tote bags and caps. Conversely, medium sizes around 11×14 inches offer a balanced approach for standard t-shirts and sweatshirts, merging visibility with aesthetic appeal.

For larger projects, sizes such as 11×17 inches and A3 are optimal for elaborate, eye-catching designs meant for full-front prints on apparel or bold promotional banners. Selecting the right size is integral not only to the visual impact of the product but also to the overall consumer experience, making it essential for designers to carefully consider their DTF printing sizes during the design process.

The Advantages of DTF Transfers

DTF transfers come with several noteworthy advantages that make them highly appealing in the world of digital printing. One of the standout features is the ability to produce high-quality prints with sharp detail and vibrant colors that stand out on fabrics. This quality makes DTF an excellent choice for those seeking to create custom apparel with intricate designs or logos that require precision.

Another significant advantage is the versatility of DTF transfers. They can adhere to a variety of fabric types, expanding the range of products one can create—from casual tees to high-end fashion apparel. Additionally, DTF technology supports low minimum order requirements, allowing smaller businesses and independent creatives to produce personalized items without large upfront costs, further fueling the demand for customized products.

Factors Affecting DTF Transfer Size Choice

Choosing the appropriate size for DTF transfers is influenced by several key factors, with the application purpose at the forefront. Designs intended for promotional events may require larger sizes for maximum visibility, while smaller designs suited for small accessories or logos can be effectively executed in compact dimensions. Understanding how the intended use impacts size selection is crucial in achieving the desired outcome.

Additionally, the design placement on the garment can dictate size choices. Front-and-center graphics may require larger transfers to ensure they are not overshadowed by the garment itself, whereas side logos or sleeve prints might elegantly utilize smaller options. Considering the dynamics of placement ensures your DTF transfers achieve optimal aesthetics and functionality.

Current Trends in DTF Printing

DTF printing has become increasingly popular in recent years, largely due to the rising trend of personalized fashion and custom designs. With consumers continually searching for unique apparel options that reflect their individual styles, DTF transfers are meeting this demand through their flexibility and ease of use. This shift is making DTF technology more accessible to small businesses and individual entrepreneurs looking to break into the market.

As the custom apparel industry continues to expand, key trend indicators show a shift towards on-demand printing practices. DTF transfers excel in this regard, as they require no minimum orders and facilitate quick turnaround times. These advantages position DTF printing at the forefront of evolving consumer preferences for customized products that reflect both artistry and personal touch.

Technical Aspects of DTF Transfers

When venturing into DTF printing, understanding the technical aspects is essential for achieving high-quality results. The size specifications of your design must align with both your printing equipment and heat press capabilities, as a misalignment can compromise the print quality. It’s imperative to ensure that designs are meticulously sized to avoid any unpleasant surprises during the application process.

Moreover, the materials used for DTF transfers heavily influence the final output. The thickness of the film and the quality of adhesives are crucial for durability, affecting how well the design adheres to fabric over time. Taking the time to select high-quality materials and understanding the temperature settings required for various sizes can vastly improve your printing outcomes and the overall longevity of the products.

Frequently Asked Questions

What are DTF transfers and how do they work?

Direct-to-Film (DTF) transfers are a printing method where designs are printed onto a special transfer film using an inkjet printer, then applied to fabric with a heat press. The adhesive powder coating allows the design to adhere securely once heated, making it suitable for various materials including cotton and polyester.

What are the different DTF printing sizes available for custom apparel?

DTF transfers come in various sizes, tailored for different applications. Common sizes include small (8×10 inches), medium (11×14 inches), and large (11×17 inches to A3 sizes). Each size serves specific purposes, from intricate logos on tote bags to full-front designs on shirts.

What are the advantages of using DTF transfers for custom apparel?

DTF transfers offer numerous advantages such as high detail and color quality, versatility across different fabric types, and cost-effectiveness for small batch printing. This makes them an excellent choice for businesses and designers looking to produce unique, custom apparel.

How can I choose the right size for my DTF transfer application?

Choosing the right size for DTF transfers depends on various factors including the application purpose, design complexity, placement on the fabric, and the type of fabric used. Large transfers are better for detailed graphics while smaller sizes suit simple logos.

What industries can benefit from DTF transfer applications?

DTF transfer applications are beneficial across multiple industries, particularly in custom apparel, promotional merchandise, and fashion. The demand for personalized items makes DTF technology appealing for small businesses and independent artists.

Are there any technical considerations when using DTF transfers?

Yes, when using DTF transfers, consider aspects such as size specifications, film thickness, adhesive quality, and appropriate heat settings. Proper alignment and understanding your equipment’s requirements are essential to achieve high-quality results.

| Size Category | Dimensions | Typical Applications |

|---|---|---|

| Small Transfers | 8×10 inches | Intricate designs, logos, patches, embellishing tote bags, caps |

| Medium Transfers | 11×14 inches | T-shirts, sweatshirts, striking designs that balance visibility and design complexity |

| Large Transfers | 11×17 inches to A3 sizes | Full-front prints on shirts, promotional banners, suitable for detailed artwork |

Summary

DTF Transfers have revolutionized the printing industry, providing a unique solution for personalized fabric printing needs. This innovative method, where designs are printed onto special film for heat transfer onto various materials, has gained traction for its high-quality, durable outcomes. Selecting the appropriate size of DTF Transfers is pivotal for achieving the desired visual impact, as it plays a crucial role in the application purpose, design placement, type of fabric, and design complexity. With the burgeoning popularity of custom apparel and the rise of independent creators looking for cost-effective yet impressive printing solutions, DTF technology is becoming increasingly prevalent. As the market for personalized products expands, understanding the nuances of DTF Transfers will empower designers and businesses to meet consumer demands effectively.