DTF transfers, or Direct-to-Film transfers, have become a game-changer in the world of custom apparel design, offering unparalleled flexibility and stunning results. As this printing technology continues to evolve, understanding how to choose DTF transfers effectively—particularly by size—becomes increasingly critical. This insight is vital for anyone seeking to create vibrant, high-quality apparel items that stand out in today’s fashion market. In this article, we will delve into the key factors to consider when selecting the appropriate transfer size to ensure that your custom designs reflect their intended impact. With the right information and a clear understanding of DTF transfer technology, you can elevate your apparel game to new heights.

Direct-to-Film transfers, commonly referred to in the industry as DTF printing, is revolutionizing how personalized clothing is created. This modern approach to printing provides an efficient way to produce intricate designs on a range of fabrics, making it essential for businesses and hobbyists alike. Understanding how to choose the right transfer size for your needs can significantly enhance your custom apparel offerings. Moreover, the ability to leverage nuances in print technology allows creators to produce eye-catching results that resonate with trends and consumer preferences. This exploration of design options and practical applications will arm you with the knowledge needed to excel in the competitive world of apparel customization.

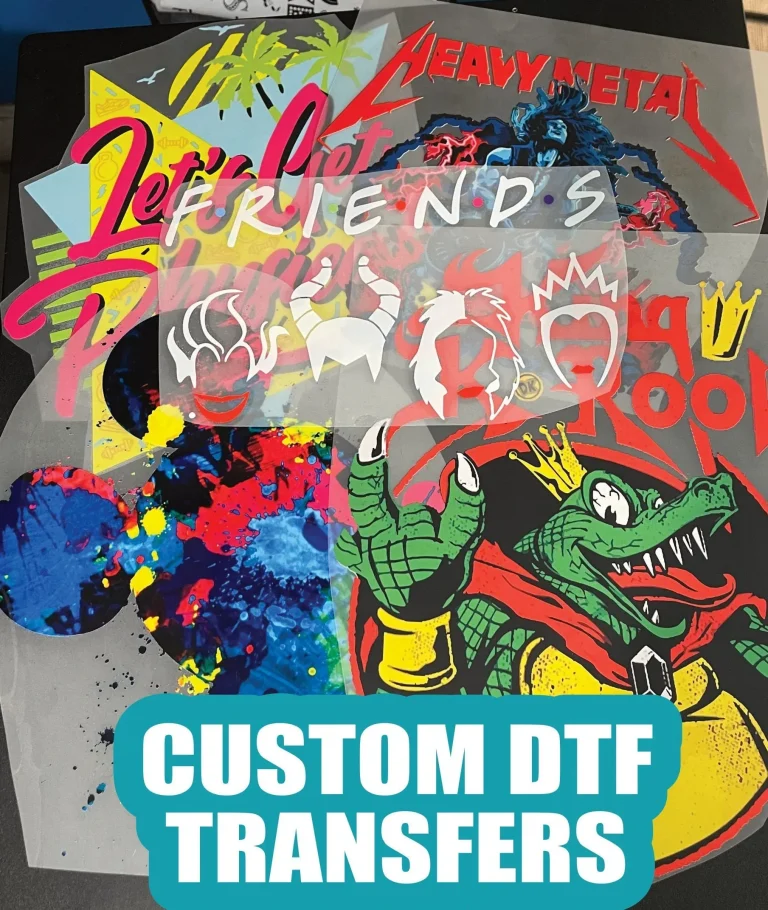

Understanding DTF Transfer Technology: A Comprehensive Overview

Direct-to-Film (DTF) transfer technology has reshaped the landscape of custom apparel printing, seamlessly blending efficiency with artistic expression. This innovative method involves intricate processes that print designs onto a special film, which can then be heat-pressed onto fabric. The result is a durable, vivid print that adheres exceptionally well, making it a preferred choice for apparel businesses and hobbyists alike. As the demand for high-quality, customizable clothing surges, understanding DTF technology’s mechanics becomes essential for maximizing its potential.

The advancement of DTF technology is marked by improved printing processes and ink formulations that enhance the vibrancy and longevity of prints. By using eco-friendly inks, manufacturers are not only catering to consumer demand for sustainable choices but are also ensuring that the finished products stand up to the challenges of regular wear and washing. Consequently, those involved in creating custom apparel find DTF transfers to be an increasingly viable option for both artistic and commercial purposes.

Choosing the Right Size for DTF Transfers: Critical Factors to Consider

When it comes to choosing the right size for DTF transfers, various elements must be taken into consideration. The complexity of the design plays a crucial role; intricate patterns often necessitate larger transfers to maintain detail and clarity. For instance, designs featuring tiny text or delicate graphics will most likely lose impact if printed too small. Thus, sizing should always prioritize preserving the integrity of the artwork while still being mindful of the overall aesthetic.

Additionally, the garment type influences the transfer size significantly. A fitted t-shirt will typically require a smaller transfer than a loose-fitting hoodie. Each garment has its unique proportions, and selecting a transfer that aligns well with these dimensions enhances the overall appearance of the final product. Therefore, understanding garment styles is directly linked to successful DTF transfer application.

Application Area Considerations for DTF Transfers

The application area is a critical determinant in selecting DTF transfer sizes. Different sections of a garment will accommodate various transfer dimensions. For example, a smaller logo on the chest of a t-shirt necessitates a different size than a bold graphic placed prominently on the back. Knowing how each placement impacts the visual outcome can help in choosing the appropriate size that not only fits the area but also enhances the garment’s design.

Furthermore, the aesthetic balance of the transfer in relation to the garment is crucial. An oversized transfer may overwhelm the design, while too small of a transfer could make it look insignificant. Therefore, by carefully assessing the application area and understanding its visual dynamics, designers can create a harmonious balance that elevates the style of the entire piece.

Exploring Market Trends in DTF Transfers

Staying informed about market trends is vital in the competitive landscape of DTF transfers. Recently, there has been a noticeable shift towards larger, bolder designs that resonate with contemporary fashion sensibilities. Consumers are leaning towards apparel that makes a statement, including oversized graphics. This trend highlights the importance of selecting transfer sizes that align with current market preferences, ensuring that designs remain relevant and appealing.

Understanding these trends not only aids in size selection but also in predicting customer behavior and preferences. By employing greater sizes that meet current demands, businesses can capitalize on consumer interest and ultimately drive sales. Therefore, keeping tabs on evolving design trends is essential for effective DTF transfer customization.

The Importance of Testing DTF Transfer Sizes

When optimizing DTF transfer sizes, experimenting and testing various options is crucial. By conducting trials with different dimensions for the same design, you can observe which size yields the best quality once printed on fabric. This empirical approach allows for adjustments based on physical outcomes, ensuring the selected size maintains the design’s integrity after the application process.

Moreover, testing different sizes can reveal preferences specific to the garment type. Some fabrics may react differently to prints, impacting the final look. By making size comparisons and learning through practical application, businesses can refine their techniques to maximize the effectiveness of their DTF transfers, ensuring a high-quality product that aligns with customer expectations.

Recent Innovations in DTF Technology and Their Impact

Recent innovations in DTF printing technology are transforming how designs are adapted and printed. These advancements have led to new formulations of inks that are more vibrant and durable, ensuring that the quality of prints remains consistent over time. Additionally, the evolution of transfer films has allowed for more intricate designs to show through, providing an opportunity for more detailed customization on a variety of fabric types.

Moreover, the industry’s focus on sustainability has given rise to eco-conscious products that maintain exceptional aesthetic qualities while reducing environmental impact. As these advancements continue to unfold, keeping abreast of technological changes will allow businesses to utilize cutting-edge techniques that not only meet market demands but also promote responsible production practices.

Frequently Asked Questions

What are DTF transfers and how do they work?

**Direct-to-Film (DTF) transfers** are a modern printing method where designs are printed onto a specially designed film. This film is then heat-pressed onto fabric, resulting in high-quality, vibrant images perfect for custom apparel. The process allows for intricate details and is versatile across various garment types.

How do I choose the right size for DTF transfers?

When selecting the size for your **DTF transfers**, consider factors such as design complexity, garment type, and the application area. Larger sizes tend to preserve intricate details better, while smaller sizes may be suitable for more subtle designs. It’s essential to match the transfer size to the garment style and placement for optimal results.

What design elements affect DTF transfer size selection?

The complexity and detail of your design significantly influence **DTF transfer size**. Intricate designs usually require larger transfers to maintain clarity. Ensure that your size choice enhances the design without compromising the quality, particularly for fine lines or text, as they can be lost in smaller formats.

What garment types require different DTF transfer sizes?

Different garments necessitate varying **DTF transfer sizes**. For example, t-shirts typically require smaller transfers compared to larger garments like hoodies or jackets. Always consider the dimensions and style of the target garment when deciding on the transfer size.

How can market trends influence my choice of DTF transfer sizes?

Staying updated on current market trends can significantly impact your choice of sizes for **DTF transfers**. Recently, oversized designs have become popular, aligning with fashion trends. Adapting to these preferences can enhance the appeal of your custom apparel and attract more consumers.

Why is testing important when selecting DTF transfer sizes?

Testing different sizes of **DTF transfers** is crucial for achieving the best results. By experimenting with various sizes on the same design, you can assess how they appear on actual garments and refine your sizing choices based on real-world outcomes, ensuring high-quality, professional finishes.

| Key Consideration | Details |

|---|---|

| Design Complexity and Detail | Larger transfers retain intricate details better, vital for designs with fine lines or small text. |

| Garment Type | Different garments require different transfer sizes; size for t-shirts may differ from hoodies. |

| Application Area | Size varies based on where the transfer is placed, e.g., front vs. back of the shirt. |

| Market Trends | Oversized designs are trending, influencing custom order sizes. |

| Testing and Sampling | Testing different sizes can help identify the best fit for the specific printer and material. |

Summary

DTF transfers have revolutionized the apparel industry by offering a high-quality, versatile method for customizing garments. Choosing DTF transfers by size is a paramount aspect of this process that requires attention to design complexity, garment type, application area, and current market trends. The ability to conduct thorough testing ensures that the final product meets quality standards while staying in line with consumer preferences. With ongoing advancements in DTF technology, entrepreneurs and enthusiasts in the customization space can achieve vibrant, durable prints, making DTF transfers an essential tool in today’s fashion landscape.