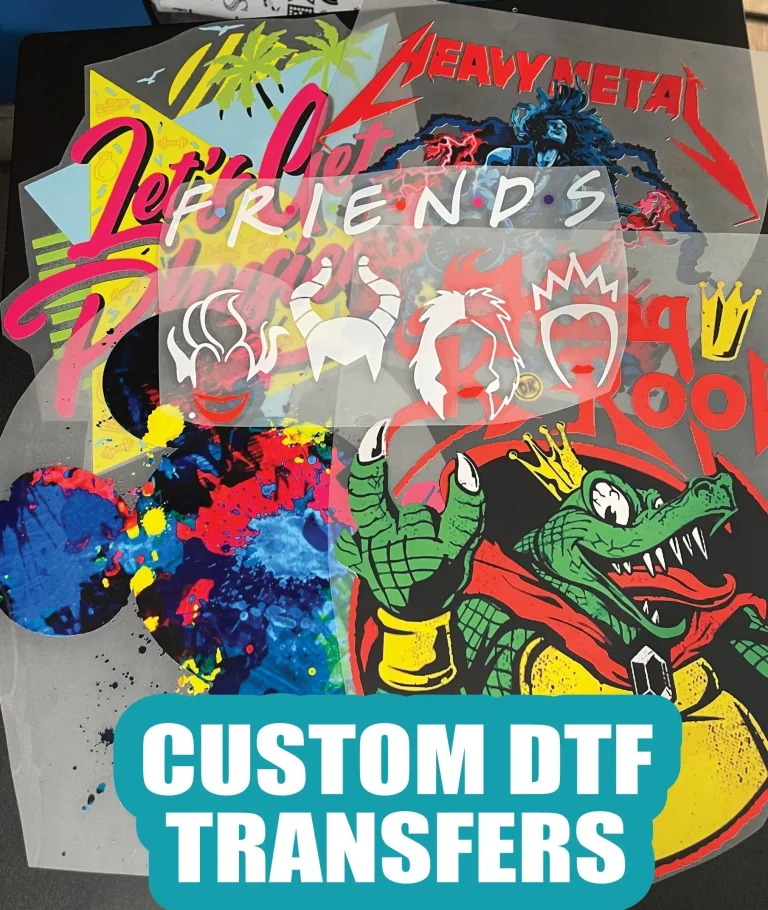

In the ever-evolving world of garment printing, **DTF transfers** have emerged as a groundbreaking technology, revolutionizing how designs are brought to life on fabric. Direct-to-Film transfers allow for vibrant colors and intricate details, making them ideal for custom apparel that stands out in crowded markets. As the demand for personalized clothing continues to rise, understanding the nuances of DTF transfers has never been more crucial. This method not only enhances design clarity but also supports eco-friendly printing initiatives, appealing to the environmentally conscious consumer. In this exploration, we will delve into how the size of DTF transfers plays a pivotal role in achieving stunning results, optimizing production efficiency, and meeting contemporary market trends.

Understanding Direct-to-Film transfers, commonly referred to as DTF transfers, is essential for those looking to innovate in custom garment printing. This cutting-edge technique merges high-quality printing with the flexibility to create unique designs for various textiles. Moreover, alternative terms like “custom transfers” have surfaced, highlighting the growing preference for tailor-made solutions that resonate with individual styles. By leveraging eco-friendly printing methods and ensuring exceptional design clarity, this advanced printing option is swiftly gaining traction among both manufacturers and consumers alike. In this discussion, we will highlight the importance of transfer sizing and its significant impact on the overall effectiveness of DTF technology.

Understanding the Benefits of DTF Transfers

Direct-to-Film (DTF) transfers have revolutionized the garment printing industry by offering unparalleled vibrancy and detail in designs. This printing technique allows artists and designers to translate their creativity onto various fabrics with exceptional accuracy. DTF transfers ensure that colors remain bold and striking, regardless of the fabric texture, making them ideal for customized apparel. Moreover, the ability to produce intricate designs without loss of clarity enhances the appeal of custom garments, meeting the diverse needs of consumers today.

Aside from aesthetic benefits, DTF transfers are gaining popularity due to their versatility and ease of application. With an array of fabric types that can be printed on, DTF transfers effectively cater to a wide range of fashion items, from t-shirts to handbags. The flexibility of application techniques allows for a seamless integration of the design onto the garment, whether the project requires large, vivid imagery or smaller, subtle logos. As demand continues to increase, manufacturers are finding innovative ways to optimize DTF methods for maximum impact.

The Crucial Role of Transfer Size in Design Clarity

The significance of transfer size cannot be understated when it comes to achieving high levels of design clarity in DTF printing. Larger transfers grant sufficient space for detailed artwork, ensuring that fine details and gradients are visible. When artists create complex designs intending to convey a specific message or aesthetic, utilizing the correct size is essential for the final output. A small transfer may result in overlooked elements, which can detract from the overall intention of the design, ultimately affecting customer satisfaction.

Conversely, utilizing oversized transfers on smaller garments can lead to similar issues, diminishing the overall appearance of the product. Designers must understand their target audience and the intended use of each garment to select the appropriate transfer size. By doing so, they can enhance design clarity, ensuring that key elements are not compromised while maintaining the garment’s integrity. This attention to detail in sizing is a critical factor in fostering positive consumer relationships and repeat business.

Techniques for Effective Application of DTF Transfers

Applying DTF transfers successfully requires more than just selecting the right size; it also involves mastering various application techniques tailored to the transfer dimensions. For larger projects, using a high-quality heat press is important to apply even heat and pressure, which ensures that the transfer bonds well with the fabric. This uniformity is crucial in elevating the longevity of the design while preventing issues like peeling or cracking that can arise from improper application.

On the other hand, smaller transfers allow for more versatile application methods. Tools such as handheld heat presses or conventional household irons can be effectively used, granting DIY enthusiasts an opportunity to engage in garment customizations without the need for specialized equipment. Understanding and utilizing the correct application techniques based on transfer size not only maximizes design effectiveness but also makes the process accessible to a wider audience.

Fabric Compatibility and Its Impact on Transfer Size

Choosing the right transfer size goes hand-in-hand with understanding fabric compatibility in DTF applications. Each garment type has specific areas that may lend themselves better to certain transfer sizes. For instance, smaller DTF transfers are often ideal for placements on sleeves or necklines, where a more discreet design enhances the overall garment without overwhelming the space. Larger transfers, on the other hand, tend to draw more attention and are well-suited for the main body of hoodies or t-shirts, capitalizing on the canvas provided by bigger fabric areas.

This compatibility plays a significant role in ensuring that designs align with the expectations of target consumers. Properly sizing transfers to complement the fabric not only improves visual appeal but also enhances the wearability and comfort of the garment. Brands that effectively address these considerations are better positioned to satisfy customer desires, as they reflect an understanding of design utility in their product offerings.

Navigating Market Trends in DTF Printing

As consumer preferences evolve, the landscape of DTF printing witnesses significant shifts, particularly concerning design size and personalization. The increasing desire for unique, custom garments drives the need for manufacturers to pivot towards providing a range of transfer sizes. This trend is indicative of a market that values individuality, where consumers seek out designs that reflect their personality through custom transfers.

Furthermore, the rise in popularity of custom-sized transfers poses an exciting challenge and opportunity for brands to innovate. Products such as tote bags, caps, and activewear are now being designed with size-specific considerations in mind, enabling brands to create targeted offerings that resonate with individual consumers. Staying ahead of these trends is vital for businesses aiming to carve out a competitive edge in the ever-changing fashion landscape.

Enhancing Production Efficiency with Proper Sizing

Production efficiency is another critical aspect that hinges on the proper sizing of DTF transfers. Oversized transfers not only waste materials but may also complicate the application process, leading to increased production costs and wasted time. For businesses aiming to maximize profitability, careful consideration of transfer sizes relative to garment dimensions is essential, promoting a streamlined workflow and sustainable output practices.

On the flip side, neglecting sizing considerations may lead to subpar designs that fail to meet market standards, resulting in lost sales opportunities. Implementing strategic measures to tailor transfer sizes to specific garment categories helps mitigate risks associated with production inefficiencies. Ultimately, embracing the importance of proper sizing is crucial for brands looking to enhance their production capabilities while delivering high-quality products.

Frequently Asked Questions

What are DTF transfers and how do they work in garment printing?

Direct-to-Film (DTF) transfers are a printing method where designs are printed onto a special film that adheres to fabric using heat and pressure. This allows for vibrant and detailed designs that can be applied to various garments.

How does transfer size affect design clarity in DTF transfers?

In DTF transfers, the size of the transfer plays a crucial role in design clarity. Larger transfers can showcase intricate details and vibrant colors more effectively, whereas smaller transfers may result in lost details, making the design less impactful.

What are the application techniques for different DTF transfer sizes?

Larger DTF transfers typically require a high-quality heat press to ensure even heat distribution, while smaller transfers can be applied using handheld heat presses or even irons. Choosing the right technique for each size is essential to achieve a lasting bond with the fabric.

Which fabrics are best suited for DTF transfers and how does size matter?

The type of fabric influences the size of DTF transfers. Smaller transfers are ideal for areas like sleeves or necklines, while larger garments like hoodies can accommodate bigger designs. Selecting the right size based on fabric type ensures a better fit and enhances the garment’s overall appearance.

What market trends are influencing the demand for custom DTF transfers?

The rising consumer preference for personalized clothing is driving the demand for custom-sized DTF transfers. Brands that recognize the importance of offering tailored transfer sizes for various products, such as tote bags and athletic gear, are better positioned to meet market demands.

Are there eco-friendly options available for DTF transfers?

Yes, the DTF transfer process is evolving towards eco-friendly printing methods. Sustainable films and inks are increasingly used in DTF transfers to cater to environmentally-conscious consumers who prioritize greener options in garment printing.

| Aspect | Key Points |

|---|---|

| Design Clarity and Detail | Larger transfers allow for intricate designs, showcasing fine details that smaller transfers may miss. |

| Application Techniques | Different sizes require specific techniques, with larger transfers often needing higher-quality heat presses. |

| Fabric Compatibility | Smaller transfers suit smaller fabric areas, while larger designs attract more attention on big garments. |

| Market Trends | There is a rising demand for personalized designs, making sizing crucial for businesses. |

| Efficiency and Cost | Proper sizing avoids material waste and enhances sales potential; too large or small can hurt profitability. |

| Technological Advancements | Recent technology improvements allow for greater precision in transfer sizing. |

| Eco-Friendly Materials | Sustainable films and inks are being adopted for DTF transfers as consumer awareness grows. |

| Training and Resources | Emerging resources are helping businesses optimize their DTF transfer processes by focusing on sizing. |

Summary

DTF transfers are revolutionizing garment printing by providing exceptional quality and versatility in design application. Understanding transfer size is essential for achieving the best possible outcomes, as it influences design clarity, application techniques, fabric compatibility, market trends, and overall production efficiency. As brands increasingly cater to personalized consumer demands, optimizing the size of DTF transfers will play a significant role in maximizing profitability and maintaining competitiveness. Continued advancements in technology and a shift towards eco-friendly materials further enhance the appeal and effectiveness of DTF transfers, paving the way for a more sustainable and innovative future in the garment printing industry.