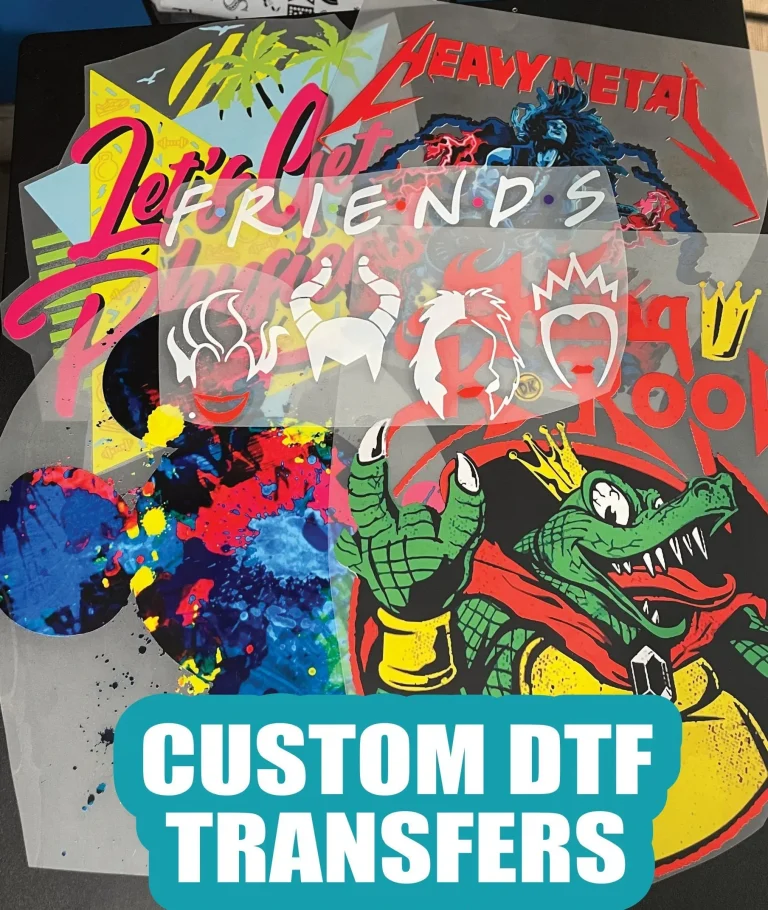

DTF Transfers, or Direct-to-Film printing, are revolutionizing the custom apparel printing industry with their innovative approach to creating detailed and vibrant designs on textiles. This advanced textile printing method involves printing directly onto a specialized film, which is then heat transferred onto various fabrics, enabling the reproduction of stunning graphics and colors. One of the key benefits of DTF transfers is their versatility in DTF printing sizes, accommodating everything from small logos to larger back prints with remarkable clarity. As businesses and creators explore DTF transfer techniques, they discover a solution that combines efficiency with high-quality output, pushing the boundaries of what’s possible in apparel design. In this article, we will explore the intricacies of DTF transfers by size, offering insights that will help you achieve impactful prints for your custom projects.

Also known as Direct-to-Film transfer printing, this contemporary method is gaining popularity among fashion and merchandise creators alike. By enabling intricate designs to be effortlessly applied to fabrics, DTF transfers provide a seamless solution for businesses focused on custom apparel production. The technology behind Direct-to-Film printing allows for a range of sizes, making it adaptable for various applications, from t-shirt graphics to promotional merchandise. With remarkable precision and color saturation, this textile printing method continues to evolve, attracting more users who are keen to leverage innovative printing techniques for their projects. In the following sections, we will delve deeper into understanding the significance of DTF printing sizes and how they can influence the overall quality and appeal of your designs.

The Essentials of DTF Transfer Techniques

DTF transfer techniques are at the forefront of modern custom apparel printing, bringing with them a multitude of benefits. The process is relatively simple: an image is printed onto a special film, followed by the application of an adhesive layer. This results in a high-quality transfer that can be applied to various fabrics. Mastering these techniques is crucial for ensuring vibrancy and detail in your designs, especially when considering different DTF printing sizes.

Using DTF transfer techniques, designers can achieve fine details and stunning color accuracy that are often difficult to replicate with traditional methods. Incorporating various textures and effects into designs is also feasible, thanks to the adaptability of DTF printing technology. Each technique, whether it be layering colors or using high-resolution images, plays a vital role in achieving the desired outcome.

Understanding DTF Printing Sizes for Perfect Prints

One of the most significant aspects of DTF printing is understanding the sizes in which transfers can be created. DTF printing sizes range from small designs, which can be as little as 2 inches for logos, to large prints over 12 inches used in full-back designs. The size selection is critical as it influences design clarity, visibility, production costs, and customer satisfaction. Designers must ensure that their artwork is tailored to the intended size to prevent any loss of detail.

Furthermore, it is essential to recognize that fabric types may influence the appropriate DTF printing size as well. For instance, a design suitable for a sturdy cotton t-shirt may appear entirely different on lighter fabrics. Therefore, experimenting with various DTF transfer sizes and fabrics will yield insights into how best to approach your custom apparel projects.

Best Practices for Successful DTF Transfers

Maximizing the results from your DTF transfers entails following some best practices that cater to quality and efficiency. Testing different sizes and materials can help identify which combinations yield the best visual results. Conducting sample tests before full production is a necessary step to ensure desired outcomes, as this helps in fine-tuning settings on heat presses and inks.

Investing in high-quality materials is another vital aspect of achieving perfect prints. Using superior films, inks, and tools not only enhances the durability of designs but also ensures vibrant colors and reliable transfers. Stay informed about the latest technology and advancements in DTF printing to enhance your production quality consistently.

Color Management for DTF Printing Success

Effective color management is integral to the success of DTF printing. Different output techniques can yield varied color results based on the materials and processes used. Therefore, using the correct color profile and conducting sample prints can significantly aid in aligning the printed output with expectations. This step minimizes disappointments and ensures that designs appear as envisioned on the chosen fabric.

Moreover, considering that DTF transfers can differ in appearance from screen prints, careful adjustment and testing of colors is necessary. Developing a systematic approach to managing color through the selection of the right PMS (Pantone Matching System) colors will help in achieving superior accuracy, confidence in display, and ultimately, client satisfaction.

Market Trends and Demand for DTF Transfers

The demand for DTF transfers has surged, especially among entrepreneurs in the custom apparel market. Businesses are increasingly capitalizing on this trend to offer personalized merchandise while keeping production costs manageable. DTF printing allows for low minimum orders, making it easy for new ventures to enter the market without hefty investments in inventory.

As the competitive landscape grows, understanding market trends becomes essential. Start-ups tend to favor DTF printing not only for its flexibility but also for its ability to provide numerous printing sizes that cater to diverse consumer needs. By adapting to trends, businesses can position themselves successfully and meet rising customer expectations for customization.

Advantages of Direct-to-Film Printing in Apparel Design

Direct-to-Film (DTF) printing offers significant advantages that make it a preferred choice for many apparel designers. One notable benefit is the capability of producing high-quality graphics with vibrant colors and intricate details. The process allows designers to bring their creative visions to life, enabling the reproduction of complex artwork that ensures design authenticity.

Additionally, DTF transfers are versatile, suitable for various fabric types including cotton, polyester, and blends. This versatility allows businesses to diversify their product offerings, catering to a wider audience and enhancing potential profitability. As such, utilizing DTF printing technology not only simplifies the production process but also elevates the quality of the final product.

Frequently Asked Questions

What are DTF transfers and how do they differ from other printing methods?

DTF transfers, or Direct-to-Film transfers, work by printing designs onto a special film before applying an adhesive and transferring the image onto fabric using heat. Unlike traditional screen printing, DTF printing allows for vibrant color outputs and fine details, making it ideal for custom apparel printing.

How should I choose the right size for my DTF transfer?

Choosing the right size for your DTF transfer is crucial for visibility and detail retention. Small transfers (2-6 inches) are great for logos, while medium (6-12 inches) and large (12 inches and above) are suited for designs on main garment areas. Proper size selection helps prevent issues like pixelation.

What are the best practices for preparing artwork for DTF printing?

To optimize your artwork for DTF printing, use high-resolution images (300 DPI or higher) or vector files for scalability. Pay attention to color management, ensuring the right color profiles are applied to achieve accurate color reproduction in your DTF transfers.

What common mistakes should I avoid when using DTF transfer techniques?

Common mistakes in DTF printing include using low-resolution images, neglecting proper size adjustments, and failing to test color samples before the final print run. Always conduct sample tests to ensure quality and clarity in your DTF transfers.

How does DTF printing support custom apparel businesses?

DTF printing is particularly beneficial for custom apparel businesses as it allows for low minimum orders and offers high customization potential. This flexibility helps startups and small businesses meet diverse customer needs without heavy upfront investments in equipment.

What advancements are being made in DTF transfer technology?

Recent advancements in DTF transfer technology include improved inks and films that enhance color vibrancy and durability. These innovations lead to higher precision and better overall print quality, allowing businesses to offer superior DTF prints that stand out in the market.

| Key Area | Details |

|---|---|

| Introduction | Overview of DTF printing and its advantages. |

| Understanding Sizes | Importance of adjusting print sizes for quality outputs. |

| Design Considerations | Use high-resolution images and proper color management. |

| Types of Transfers | Different size categories: small, medium, large. |

| Market Trends | Rising demand for DTF transfers among startups and e-commerce. |

| Best Practices | Experiment with sizes, conduct sample tests, invest in quality. |

| Technology Advancements | Improvements in technology enhance DTF printing quality. |

Summary

DTF Transfers are becoming increasingly significant in the world of textile printing, with their ability to deliver highly detailed designs onto fabrics. Understanding the impact of size on print quality is crucial for achieving vibrant and sharp outputs. By utilizing best practices such as high-resolution images and meticulous color management, businesses can optimize their designs for various transfer sizes. As the market for custom apparel continues to grow, leveraging advancements in DTF technology ensures that companies remain competitive, producing prints that not only meet but exceed customer expectations. Overall, mastering DTF transfers by size prepares businesses for success in a rapidly evolving marketplace.