DTF transfers, or Direct-to-Film transfers, have revolutionized the realm of custom apparel printing, providing businesses with a dynamic printing solution that combines quality with versatility. This innovative printing technology excels at producing high-resolution designs that stand out, making it ideal for creating striking custom merchandise. Among the many DTF printing benefits, its ability to accommodate various fabric types and maintain vibrant colors after multiple washes is particularly noteworthy. Moreover, as sustainability becomes a significant consideration for consumers, DTF printing offers eco-friendly advantages through the use of water-based inks and reduced waste production. In this article, we’ll delve into the top five benefits of using DTF transfers, showcasing why this method is a compelling choice for modern businesses.

Direct-to-Film (DTF) transfer technology represents a breakthrough in custom printing processes, enabling the creation of high-quality graphics on a wide array of materials. This method, often referred to as direct-to-film printing, leverages advanced formats to facilitate efficient and detailed designs tailored for various fabric types. Recognized for its versatility and cost-effectiveness, this type of printing is becoming increasingly popular among small to medium-sized enterprises that seek to offer unique apparel without the traditional barriers. Additionally, the eco-conscious nature of DTF printing aligns well with today’s demands for sustainable printing practices, allowing businesses to appeal to a growing demographic of environmentally aware customers. As we explore the myriad advantages of DTF transfers, it becomes clear that this technology is poised to transform how businesses approach custom apparel production.

Understanding DTF Transfers: A Revolutionary Printing Technique

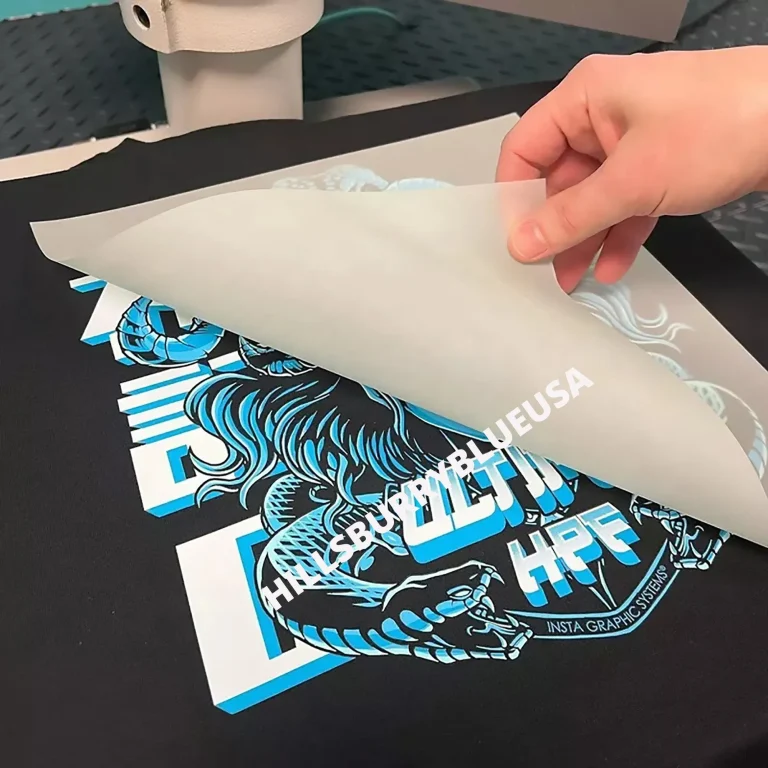

Direct-to-Film (DTF) transfers represent a significant advancement in printing technology that combines flexibility and quality. With DTF, designs are printed onto a special film utilizing a unique printing process that allows for vibrant colors and superior detailing. This method has gained popularity among custom apparel businesses because it produces prints that are not only visually stunning but also capable of withstanding the rigors of washing and wear. By eliminating common issues faced with more traditional methods like screen printing and direct-to-garment printing, DTF offers businesses an innovative tool to elevate their product offerings.

Moreover, the application of DTF transfers extends beyond just fabric. Business owners can explore various materials, opening possibilities for customization on items such as bags, hats, and even hard surfaces. This versatility in application allows businesses to cater to a broad audience and meet diverse customer needs, making DTF a valuable asset in any custom printing portfolio.

Unmatched Quality: Why DTF Printing Stands Out

One of the most compelling advantages of DTF printing is the exceptional print quality it provides. With this technology, vibrant colors and intricate designs come to life, leveraging modern advancements in printing technology. DTF transfers not only achieve a high level of detail but also ensure that the prints remain durable after repeated washes, unlike other printing methods that may fade or crack over time. This quality consistency is vital for businesses looking to build a strong brand identity that resonates with customers.

Additionally, the printing process involved in DTF allows for a superior representation of various gradients and shades, accommodating complex artwork effortlessly. This capability enables businesses to create compelling visuals that captivate potential buyers, making DTF an excellent choice for custom apparel that demands high aesthetic standards.

Versatility of DTF Transfers Across Different Fabrics

DTF transfers shine in their adaptability across a range of materials. Whether working with cotton, polyester, blends, or even specialized textiles, this printing method offers immense flexibility for custom apparel businesses. The method’s capability to handle various fabrics without the need for extensive adjustments or machinery makes it an attractive option for business owners looking to diversify their product lines without significant overhead costs.

This versatility not only allows businesses to cater to various consumer demands but also enhances their ability to seize new market trends quickly. For example, a brand that traditionally focuses on printing t-shirts can easily transition to producing apparel like jackets or trousers, thanks to the compatibility of DTF with diverse materials. Consequently, this flexibility contributes directly to increased sales opportunities and customer satisfaction.

Enhancing Production Efficiency with DTF Printing

Efficiency is paramount in today’s fast-paced commercial environment, and DTF printing exemplifies streamlined production processes. This method significantly reduces setup time, allowing businesses to fulfill orders faster, which is vital in the face of rising consumer expectations for quick turnaround times. DTF transfers enable smaller runs at lower costs, which means businesses can respond to orders and market demands without incurring losses associated with excess inventory.

Furthermore, the ability to adapt production quickly makes DTF printing especially appealing for custom print-on-demand services. As consumer preferences shift and trends evolve, businesses that can pivot and offer fresh designs will have a competitive edge. By embracing DTF technology, companies are better positioned to maintain relevance and meet the ever-changing needs of their customer base.

Cost-Effective Solutions for Small and Medium Businesses

At the heart of any burgeoning business are concerns about profitability and cost management. DTF printing emerges as a cost-effective solution for small and medium-sized businesses eager to enter the custom apparel market. The relatively lower initial investment required for DTF equipment and supplies compared to alternative methods like Direct-to-Garment (DTG) printing reduces the financial barriers associated with starting a printing business.

With more budget-friendly options available, entrepreneurs can allocate funds to other essential areas such as marketing strategies or enhancing product offerings. The strategic balance of cost management and investment in growth translates into increased opportunities for scaling operations and expanding market reach, essential elements for long-term business success.

Commitment to Sustainability with DTF Transfers

As the world increasingly turns its focus toward sustainability, DTF printing stands out as a responsible choice for businesses keen on minimizing their environmental footprint. The use of water-based inks in DTF transfers is significantly less harmful to the environment compared to the solvent-based inks commonly utilized in traditional printing techniques. This eco-friendly approach appeals to today’s conscientious consumers who favor brands committed to sustainable practices.

Moreover, the efficiency of the DTF printing process results in minimal waste production, aligning with larger sustainability goals. By adopting DTF technology, businesses not only enhance their operational efficiency but also position themselves favorably in the eyes of consumers who prioritize environmental responsibility. Such alignment reinforces a brand’s image and builds loyalty among eco-conscious customers.

Frequently Asked Questions

What are the main benefits of using DTF transfers for custom apparel printing?

DTF transfers offer several key benefits for custom apparel printing, including high print quality, versatility across various materials, efficient production processes, lower upfront investment costs, and reduced environmental impact. These advantages make DTF printing an attractive option for businesses looking to enhance their product offerings.

How does DTF printing compare to other printing technologies?

DTF printing stands out from other printing technologies like screen printing and DTG (direct-to-garment) by delivering vibrant colors and durability, allowing for complex designs on a variety of fabrics. Its efficient production process and lower initial setup costs further differentiate it as a competitive option in the custom apparel market.

Can DTF transfers be used on different materials?

Yes, DTF transfers are highly versatile and can be used on a wide range of materials, including cotton, polyester, and blends. This versatility enables businesses to create custom apparel across various product types without needing additional printing equipment.

What makes DTF printing an eco-friendly choice?

DTF printing is considered eco-friendly because it utilizes water-based inks, which are less harmful to the environment compared to solvent-based inks in traditional methods. Additionally, the DTF process generates less waste, aligning with sustainable printing practices that appeal to environmentally conscious consumers.

Is the initial investment for DTF printing higher than other methods?

No, DTF printing typically requires a lower initial investment compared to other printing methods like DTG. This affordability makes DTF technology an accessible option for small and medium-sized businesses looking to expand their custom printing capabilities without incurring high startup costs.

How does DTF transfers enhance production efficiency?

DTF transfers improve production efficiency by streamlining the printing process, requiring less setup time and resources than traditional methods. This allows businesses to quickly fulfill smaller orders at cost-effective prices, thus enhancing customer satisfaction and enabling rapid response to market trends.

| Benefits of DTF Transfers | Description |

|---|---|

| High-Quality Prints | Produces vibrant colors and smooth gradients; durable and maintains quality over time. |

| Versatility Across Materials | Can print on various fabric types and non-textile surfaces, offering full flexibility. |

| Efficient Production Process | Streamlined setup with rapid order fulfillment, suitable for print-on-demand. |

| Lower Initial Investment | Requires less expensive equipment, making it accessible for small businesses. |

| Reduced Waste and Eco-Friendliness | Water-based inks and minimal waste align with sustainable practices. |

Summary

DTF transfers are revolutionizing custom printing for businesses by offering multiple benefits that enhance both quality and efficiency. From producing high-quality prints that are vibrant and durable, to providing versatility across a wide variety of materials, DTF transfers offer an excellent solution for those looking to diversify their product offerings. Additionally, the efficient production process coupled with lower initial investment costs makes these transfers a viable choice for small and medium-sized businesses. Moreover, the eco-friendliness of DTF printing practices aligns with the growing consumer demand for sustainable production methods. In summary, adopting DTF transfers can significantly boost a business’s ability to meet customer demands while maintaining a commitment to quality and sustainability.