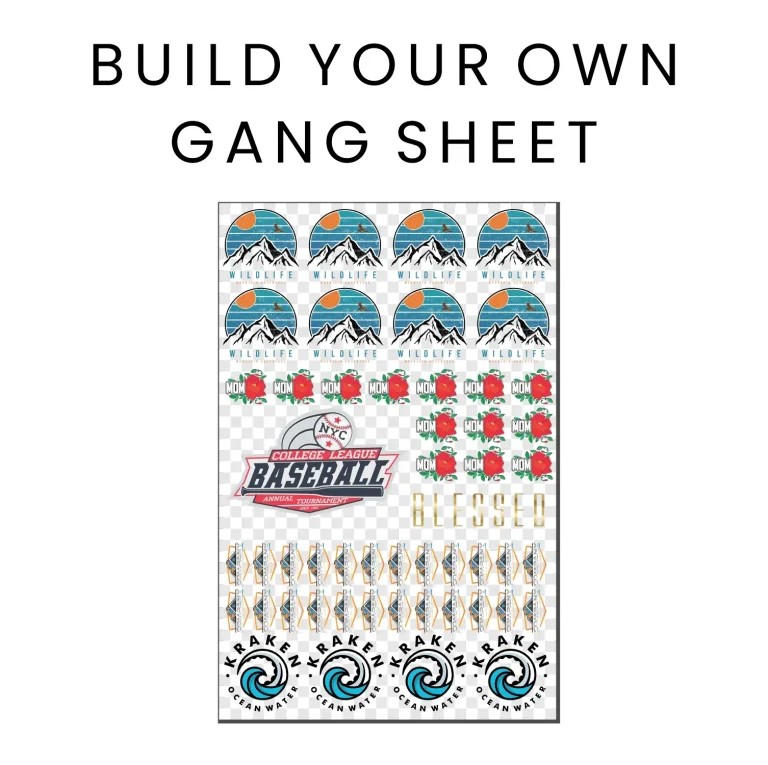

The DTF Gangsheet Builder is a groundbreaking tool that has transformed the world of DTF printing, enabling users to create multiple designs on a single sheet with incredible efficiency. As the demand for custom apparel continues to rise, mastering the gang sheet technique proves vital for maximizing production while minimizing waste. This innovative approach not only streamlines the printing workflow but also enhances DTF printing quality, ensuring vibrant and detailed graphics on various fabrics. In this article, we will explore essential DTF printing tips to make the most of the DTF Gangsheet Builder, guiding you through each step to optimize your creations. Whether you’re a seasoned professional or a newcomer eager to learn how to use gang sheets, this guide will provide insights that can elevate your printing game.

The Direct-to-Film (DTF) Gangsheet Builder offers a unique solution for those engaged in custom fabric printing, allowing for the simultaneous processing of numerous designs on one sheet. This method, commonly referred to as the gang sheet technique, is particularly advantageous for reducing material expenses and enhancing the productivity of print jobs. By understanding the intricacies of DTF printing, including key pointers and best practices, users can ensure that their final products not only meet but exceed quality expectations. Whether discussing DTF printing maneuvers or exploring various strategies for effective gang sheet usage, this article aims to equip readers with valuable knowledge while optimizing their print projects. Embrace the efficiency of the DTF Gangsheet Builder and discover how it can revolutionize your approach to custom printing.

Understanding DTF Printing and Its Advantages

DTF printing, or Direct-to-Film printing, is an innovative technique that has transformed how designs are printed on apparel. This method utilizes specialized films that allow for precise transfers of vibrant graphics onto fabrics such as cotton and polyester. Because DTF printing uses a unique process of applying a heat transfer ink, it provides the ability to achieve intricate designs with excellent color reproduction, making it a favored choice for custom apparel creation. With the advent of the DTF Gangsheet Builder, this process becomes even more efficient, allowing for multiple designs to be printed at once.

Moreover, DTF printing is lauded for its adaptability and ability to cater to diverse projects, from small batches to mass production runs. The use of gang sheets further optimizes this process, enabling users to print several designs on one large sheet simultaneously. This not only reduces waste of printing materials but also cuts down on time spent setting up and executing print jobs, thereby enhancing overall productivity. For beginners and seasoned professionals alike, understanding the fundamentals of DTF printing is crucial to maximizing its benefits.

The Importance of Design Preparation in DTF Printing

Effective design preparation is the cornerstone of successful DTF printing. High-resolution graphics are essential when preparing designs for transfer, as low-quality images can lead to pixelation and a lack of detail in the final print. Ideally, designs should be created or scanned at a resolution of at least 300 DPI. This will ensure that every detail is captured, contributing to a vibrant and professional-looking final product. Equally important is the careful arrangement of these designs on gang sheets, which can be done with design software like Adobe Illustrator or CorelDRAW.

Proper design preparation also includes ensuring the right spacing and alignment between the various graphics on the gang sheet. By maintaining adequate space between the designs, you prevent any overlaps that could lead to undesirable print quality or wasted materials. Attention to detail in the design phase sets the foundation for a smooth printing process, ultimately leading to higher satisfaction with the output. Thus, investing time in preparing your designs meticulously pays dividends in the quality and efficiency of your DTF printing projects.

Selecting the Right Materials for Optimal DTF Results

Choosing high-quality materials is vital for achieving the best results in DTF printing. DTF films should be specifically designed for the heat transfer process, ensuring that they can withstand the high temperatures of the heat press without curling or ruining the print quality. Furthermore, opting for premium inks that offer both vibrant colors and considerable durability will significantly enhance the final output. Poor-quality inks can lead to fading and limited washability, resulting in disappointing outcomes for your custom prints.

Additionally, it’s important to consider the compatibility of materials when embarking on a DTF printing project. Using films and inks from reputable suppliers that specialize in DTF technology can prevent common pitfalls associated with low-grade materials. This careful selection process not only enhances the visual appeal of the prints but also ensures they remain intact, even through repeated laundering. By prioritizing quality in all components, you set the stage for long-lasting and stunning DTF prints.

Mastering Printer Settings for Enhanced Print Quality

Fine-tuning your printer settings is essential for achieving high-quality results in DTF printing. Calibration is a critical step in this process; it involves adjusting various parameters such as ink flow rates, temperature, and print speed to suit the specific requirements of the DTF materials being used. Properly calibrated printers can produce sharper images with accurate colors, making your designs pop on the fabric. This attention to printer settings is particularly important when dealing with complex or detailed designs that require precision.

Moreover, selecting the right print quality settings can produce varying results. Going for the highest quality options available on your printer ensures optimal clarity and color vibrancy, which are paramount in DTF printing. It is advisable to conduct test prints to fine-tune these settings before running larger batches, allowing you to troubleshoot any potential issues early on. By investing time in mastering your printer settings, you can significantly elevate the quality of your DTF prints.

Applying Adhesive Powder: Techniques for Success

Applying adhesive powder is a crucial step in the DTF printing process that should not be overlooked. This powder acts as a bonding agent that adheres the ink to the fabric during heat transfer. The key to a successful application is doing it while the ink is still wet, allowing the powder to stick evenly across the design. Techniques such as using a shaker or a screen for an even distribution can prevent clumping, which is essential for ensuring that the printed designs transfer completely and cleanly on the garments.

Even application of adhesive powder not only maximizes adhesion but also contributes to the long-term durability of the prints. Insufficient coverage can lead to peeling or fading after washes, while too much powder may cause a rough texture on the finished product. Therefore, finding the right balance and using proper techniques can make all the difference in the quality of your final output. By mastering the application of adhesive powder, you pave the way for beautifully finished DTF garments.

Heat Press Techniques for Perfect Transfers

The heat press technique is a critical component of the DTF printing process, and using it correctly can drastically affect the quality of the final print. Setting the heat press to an optimal temperature, typically around 320°F (160°C), is essential; however, adjustments may be needed based on the specific fabric or transfer film being used. Precise temperature control is crucial to ensure that the ink bonds well with the fabric without damaging either component.

Equally important is the duration and pressure applied during the transfer. A common recommendation is to press the gang sheet for anywhere between 10 to 15 seconds while maintaining firm, even pressure. This helps ensure that every part of the design adheres correctly to the fabric. Missing these critical steps can result in poor adhesion, leading to designs that peel or crack over time. By mastering the heat press technique, you can achieve professional-grade results with your DTF prints.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it improve DTF printing?

The DTF Gangsheet Builder is a tool that allows users to combine multiple designs into a single large format sheet for Direct-to-Film (DTF) printing. This technique reduces material waste and production costs by enabling simultaneous printing of several graphics, thereby increasing efficiency and maximizing production.

What are some essential DTF printing tips when using a Gangsheet Builder?

When using a DTF Gangsheet Builder, ensure your designs are high-resolution (minimum 300 DPI) for clarity. Utilize design software like Adobe Illustrator for optimal layout and spacing. Additionally, select quality DTF films and inks, calibrate your printer settings correctly, and apply adhesive powder evenly for the best results.

How do I prepare my designs for the DTF Gangsheet Builder?

To prepare designs for the DTF Gangsheet Builder, first create high-resolution graphics. Arrange designs in software such as CorelDRAW, leaving adequate space between each design to prevent overlaps. Following these steps is crucial for achieving quality DTF printing results.

What materials are best for DTF printing using a Gangsheet Builder?

For optimal results in DTF printing with a Gangsheet Builder, invest in high-quality DTF films that allow for proper adhesion and durable inks that provide vibrancy and longevity. Superior quality materials ensure better transfer and minimize issues such as fading or cracking.

Can you explain the heat press technique for DTF Gangsheet printing?

Using a heat press correctly is vital for DTF Gangsheet printing. Set the heat press to approximately 320°F (160°C) and press the gang sheets for 10-15 seconds with firm pressure. This ensures complete adhesion of the design to the fabric without damaging the material.

What post-press care should I take after applying DTF prints using a Gangsheet Builder?

After applying DTF prints, allow the garments to cure for at least 24 hours before washing. This ensures that the adhesive and inks solidify, enhancing durability. Follow proper washing instructions—wash inside-out in cold water and avoid bleach—to maintain the quality of your designs.

| Technique | Description | Tips |

|---|---|---|

| Design Preparation | Preparing high-resolution designs for printing. | Use images at minimum 300 DPI and utilize software like Adobe Illustrator. |

| Selecting Quality Materials | Choosing appropriate films and inks for durability. | Invest in high-adhesion DTF films and premium inks. |

| Printer Settings | Calibrating printer for optimal results. | Ensure high-quality print settings and calibration adjustments. |

| Applying Adhesive Powder | Evenly applying adhesive powder to wet prints. | Use a shaker or screen for even distribution. |

| Heat Press Technique | Applying heat correctly for adhesion. | Press at 320°F for 10-15 seconds with firm pressure. |

| Post-Pressing Care | Curing and maintaining printed garments. | Cure for 24 hours before washing, and wash inside-out. |

Summary

The DTF Gangsheet Builder simplifies the printing process for custom apparel, ensuring vibrant designs and efficient production. By mastering the aforementioned best techniques, users can significantly enhance their workflow and minimize resource wastage. This guide highlights critical aspects of DTF printing—from preparation and material selection to proper application techniques. As one navigates the intricacies of the DTF Gangsheet Builder, these key strategies will empower creators to produce stunning prints that succeed in a competitive marketplace.