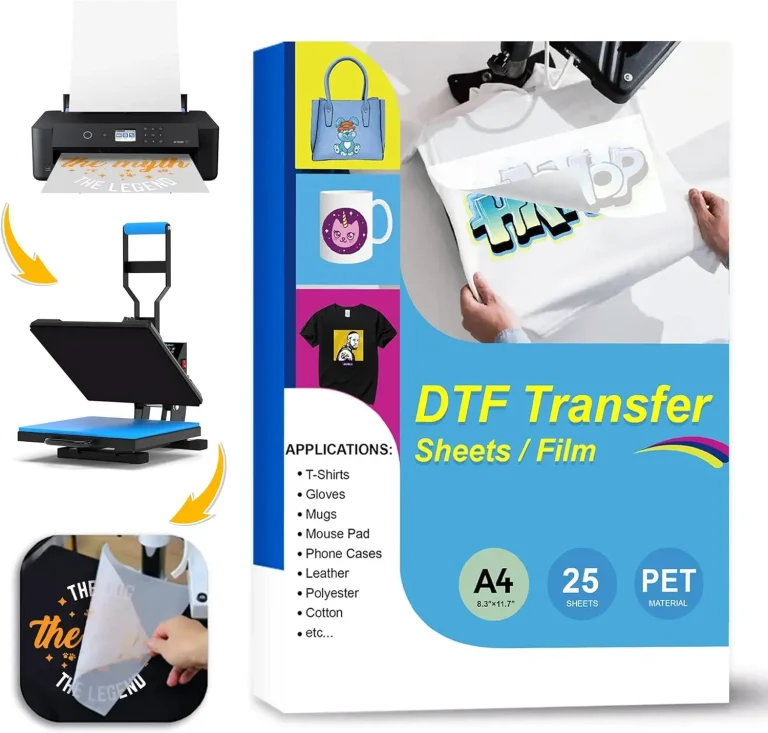

DTF transfer paper, essential for the evolving world of fabric printing, has become the go-to choice for many artists and businesses alike. This specialized transfer material allows for high-quality images to be applied onto various textiles using innovative DTF printing technology. With a plethora of options available, knowing how to choose DTF transfer paper is key to achieving optimal results for your projects. In this comprehensive guide, we’ll explore not just the best DTF transfer paper on the market, but also provide vital tips and advice that can elevate your printing to the next level. Understanding different DTF transfer paper types and their applications can make all the difference in your printing endeavors, ensuring vibrant and durable designs that attract attention and satisfy customers.

When it comes to printing on garments, the significance of proper transfer sheets cannot be overstated. The process of Direct to Film printing involves using specialized film that enhances the quality and longevity of prints on fabric. As you navigate the landscape of textile customization, it’s crucial to familiarize yourself with selecting the right transfer materials, understanding the intricate details of their application. So, if you’re eager to learn about transfer sheets for DTF methods, or if you want insights on efficient printing techniques and the most suitable products for your needs, you’ve landed in the right place. Prepare to transform your printing projects with informed choices and expert guidance.

How to Choose DTF Transfer Paper: Key Considerations

When selecting the right DTF transfer paper, one must take into account several essential factors that directly affect the printing outcome. The primary consideration is the type of fabric you intend to work with, as different transfer papers yield various results on cotton, polyester, or blended materials. For instance, soft DTF papers are ideal for cotton garments, offering a softer feel upon application. Additionally, the thickness and texture of the transfer paper should match your printing needs. Thicker papers may provide better durability, while thinner papers often allow for greater detail in designs.

Moreover, understanding the DTF technology is crucial in making an informed decision. DTF transfer papers utilize specialized films that help produce vibrant designs that adhere effortlessly to fabrics. Evaluating the manufacturer’s recommendations and the printing capabilities of the paper can also lead to improved outcomes. By taking these considerations seriously, you ensure that your chosen DTF transfer paper aligns well with your project requirements—thus, enhancing the overall quality of your prints.

Best DTF Transfer Paper: Top Products on the Market

The market is brimming with numerous DTF transfer paper options, each claiming to be the best. However, top contenders often share a few common characteristics—high-quality materials, compatibility with various printers, and the ability to produce durable, vibrant prints. Brands like ‘A-SUB’ and ‘Transfez’ consistently receive positive reviews for their DTF transfer papers due to their reliability and user-friendly features. Before making a purchase, be sure to check which types of inks and printers are compatible with these papers, as this will significantly influence your printing results.

Additionally, evaluating customer feedback and expert reviews can guide you toward the ideal transfer paper choice. Many professionals favor DTF transfer paper that not only performs well in terms of print quality but also provides value for money. Features such as the paper’s ability to withstand multiple washes without fading are also indicative of premium quality. Therefore, when searching for the best DTF transfer paper, consider investing in well-reviewed brands that assure long-lasting performance and satisfied users.

DTF Printing Guide: Essential Techniques

Embarking on your DTF printing journey requires a solid understanding of the necessary techniques to achieve optimal results. First and foremost, selecting the right transfer paper is crucial; however, preparation plays an equally essential role. Ensure that your printer settings are calibrated correctly for the type of DTF transfer paper you are using. Choosing the right ink for your prints, whether water-based or solvent-based, should align with your desired outcome—color intensity and durability.

Furthermore, attention to detail during the setup process can elevate your printing experience. Properly maintaining your printer and regularly cleaning the print heads can prevent clogged nozzles, ensuring smooth operation. Additionally, consider using high-quality adhesive powders and applying them uniformly over the printed designs—this critical step ensures that your transfers adhere effectively to the fabric, thus producing a lasting print.

DTF Transfer Paper Types Explained

Choosing the right type of DTF transfer paper can significantly influence the end result of your printing projects. Generally, DTF papers can be categorized into standard, soft, and high-density variants. Standard DTF paper is the go-to option for many users due to its versatility and consistent results across various fabric types. In contrast, soft DTF paper feels more comfortable on wearables like t-shirts and hoodies, making it a favorite among apparel designers.

High-density DTF transfer paper, however, caters to those looking to print intricate designs or detailed graphics. This specialized paper captures the nuances of your artwork, ensuring that it translates effectively onto the fabric. By understanding the different types of DTF transfer paper available, you can select the one that best suits your project specifics, ultimately enhancing the quality of your prints.

DTF Printing Tips: Achieving the Best Results

To achieve the best results in DTF printing, it is essential to adopt specific techniques that enhance the quality of your prints. Start by carefully selecting your materials, particularly when it comes to the transfer paper and inks. Remember, investing in high-quality DTF transfer paper not only results in vivid designs but also ensures durability over time. Moreover, understanding the recommended heat press settings—temperature, time, and pressure—will help in attaining successful transfers without damaging the fabric.

On the printing side, perform test prints to gauge the quality and adjust settings as necessary before running larger batches. Experimenting with small versions of your designs can provide insights into how different settings affect overall output. Incorporating these DTF printing tips will not only streamline your process but also contribute directly to creating stunning products that meet customer expectations.

Navigating DTF Transfer Paper Suppliers for Quality Assurance

Selecting the right supplier for DTF transfer paper is as important as choosing the right type itself. It is imperative to research potential suppliers thoroughly, examining their customer reviews, reputation in the industry, and overall reliability. A reputable supplier usually offers not just quality products but also excellent support and clear return policies should you encounter any issues with the transfer paper.

Look for suppliers that specialize solely in DTF printing materials, as they typically have a more profound understanding of different paper types and their applications. Establishing a relationship with a trusted supplier can significantly benefit you in the long run, ensuring that you consistently receive top-notch products that enhance the quality of your prints while building your brand’s reputation.

Frequently Asked Questions

How do I choose the right DTF transfer paper for my project?

Choosing the right DTF transfer paper involves understanding the type of fabric you’ll be printing on and the specific paper characteristics that match your needs. There are various types of DTF transfer paper available, such as standard, soft, and high-density options. Always check the manufacturer’s recommendations for compatibility with your printer and the materials you are using. Additionally, consider aspects like ink type, adhesive powder, and heat press settings to ensure optimal results.

What is the best DTF transfer paper for beginners?

For beginners, the best DTF transfer paper is typically the standard type, as it is versatile and suitable for a variety of common printing needs. It yields consistent results and works well with most fabric types. Starting with this option can help you learn the basics of DTF printing without the complexities associated with specialized papers.

What types of DTF transfer paper are available, and how do they differ?

There are several types of DTF transfer paper, including standard, soft, and high-density papers. Standard DTF transfer paper is great for general use, soft paper offers a comfortable feel for apparel, while high-density paper is ideal for intricate designs that require detailed reproduction. The choice among these types depends on your specific project requirements and desired fabric feel.

What are some essential DTF printing tips for better results?

To achieve better results in DTF printing, ensure you use compatible inks and check the printer settings for optimum performance. It’s also vital to apply adhesive powder evenly, use appropriate heat press settings (typically 320°F to 340°F for 10-15 seconds), and test transfer samples to fine-tune your approach. Understanding the characteristics of your DTF transfer paper will further enhance your print quality.

How can I ensure my DTF transfer paper is compatible with my printer?

To ensure DTF transfer paper compatibility with your printer, refer to the paper manufacturer’s specifications and confirm that your printer is an inkjet model capable of handling DTF materials. Conducting small test prints can help verify compatibility before making larger purchases.

Why is it important to balance cost and quality when selecting DTF transfer paper?

Balancing cost and quality in DTF transfer paper is crucial because lower-priced options may lead to poor print quality, which can result in higher reprint costs and customer dissatisfaction. Investing in recommended high-quality DTF transfer paper initially can save money and boost your reputation in the long run by delivering lasting, high-quality prints.

| Key Aspect | Description |

|---|---|

| Understanding DTF Technology | DTF transfer paper is designed for easy transfer to textiles with vibrant colors and durability. |

| Types of DTF Transfer Paper | Standard, Soft, and High-Density options cater to various printing needs. |

| Printer Compatibility | Not all DTF papers work with every printer; testing is advisable. |

| Quality Ink | Water-Based and Solvent-Based inks impact transfer quality significantly. |

| Adhesive Powders | Ensure compatibility and uniform application for best results. |

| Heat Press Settings | Adjust temperature, time, and pressure for successful transfers. |

| Supplier Reputation | Choosing reliable suppliers ensures quality and support. |

| Cost vs Quality | Investing in quality over low-cost papers results in better outcomes. |

Summary

DTF Transfer Paper is essential for achieving high-quality prints in the DTF printing process. By understanding the technology, types, printer compatibility, and other key factors, users can make informed decisions that enhance their printing outcomes. This comprehensive guide empowers both beginners and experienced professionals to choose the right transfer paper based on their needs, ensuring vibrant colors, durability, and ultimately satisfied customers. As you venture into your DTF printing projects, remember that a thoughtful selection process is vital to your success.