UV DTF Transfers are quickly becoming a game-changer in the world of printing technology, combining the advanced capabilities of Direct-to-Film printing with the efficiency of ultraviolet curing. This innovative method provides a robust solution for businesses seeking vibrant, durable, and high-quality prints, making it an essential topic for those involved in custom printing solutions. As environmentally conscious consumers continue to drive demand for sustainable options, UV DTF Transfers stand out with their eco-friendly inks that emit fewer volatile organic compounds compared to traditional methods. This unique combination of speed, versatility, and environmental responsibility positions UV DTF transfers at the forefront of modern printing techniques. Join us as we delve deeper into the numerous advantages that UV DTF Transfers offer to the commercial printing sector and how they are setting new standards in the industry.

The realm of custom printing technologies has witnessed a significant evolution with the introduction of ultraviolet Direct-to-Film (UV DTF) transfers. This cutting-edge printing method merges the principles of DTF printing with the fast-curing properties of UV light, paving the way for high-resolution designs that are both aesthetically pleasing and resilient. Businesses eager to enhance their product offerings can leverage this breakthrough in printing technology to achieve stunning results on various substrates, including textiles, plastics, and metals. With a growing emphasis on sustainability, UV DTF printing not only meets market demands but also aligns with eco-friendly practices by utilizing inks that minimize environmental impact. Exploring this innovative approach could provide insights into addressing the diverse needs of consumers while staying competitive in a rapidly changing market.

Understanding the Mechanics of UV DTF Printing

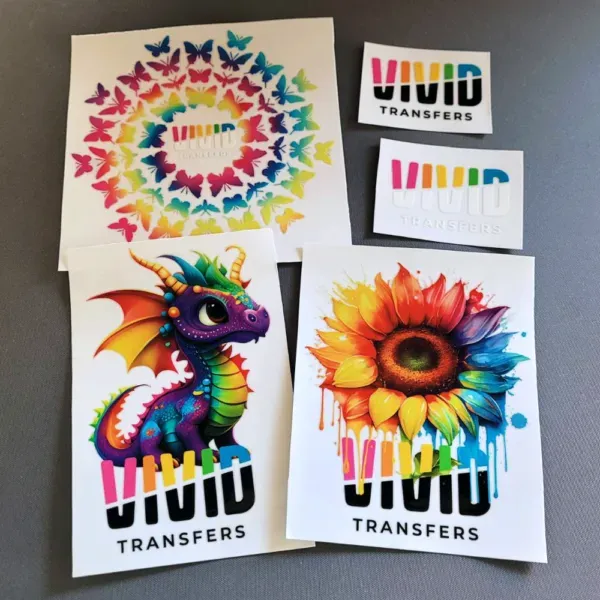

UV DTF printing is an innovative approach that combines the principles of Direct-to-Film (DTF) printing and ultraviolet curing. This process involves transferring printed designs onto a specialized film, which is subsequently applied to various substrates through heat application. A distinguishing feature of this technique is the use of UV light, which quickly cures the inks as they are printed, drastically improving production times while ensuring vibrant and lasting colors.

The significance of UV DTF printing extends beyond mere aesthetics. With its ability to produce high-quality imagery, this method is garnering attention from artists and businesses alike. Whether for promotional merchandise or custom apparel, the detailed output ensures that brands can effectively engage their audience while maintaining quality insights that align with modern consumer expectations.

Frequently Asked Questions

What are UV DTF Transfers and how do they work?

UV DTF Transfers, or UV Direct-to-Film Transfers, utilize a unique printing technology that prints designs onto a special film which is then transferred onto various substrates using a heat press. The process involves ultraviolet light curing, allowing inks to set almost instantly, making it an efficient choice for high-quality custom printing applications.

What are the benefits of using UV DTF Transfers for custom printing solutions?

The key benefits of UV DTF Transfers include exceptional durability, as the UV inks formulate a strong bond with diverse materials, ensuring prints resist fading and abrasion. Additionally, this technology supports eco-friendly printing practices with low VOC emissions, appealing to environmentally conscious consumers looking for sustainable products.

How versatile are UV DTF Transfers when it comes to substrates?

UV DTF Transfers are incredibly versatile, allowing prints to be applied to a wide range of surfaces beyond textiles, including plastics, metals, and wood. This adaptability enables businesses to explore new markets and expand their product offerings, making UV DTF an advantageous printing technology.

Can UV DTF Transfers produce high-quality images and designs?

Yes, UV DTF Transfers are known for their ability to produce vibrant colors and fine detail. This precision makes them ideal for high-quality imagery, which is why artists and designers increasingly prefer this technology for impactful custom printing solutions.

Is UV DTF printing environmentally friendly?

Absolutely! UV DTF printing is considered eco-friendly due to its use of inks that emit fewer volatile organic compounds (VOCs) compared to traditional printing methods. This aligns with the growing demand for sustainable practices in the custom printing industry, positioning UV printing technology as a greener alternative.

What challenges should businesses consider when adopting UV DTF Transfers?

While the advantages of UV DTF Transfers are considerable, challenges include the initial investment in advanced equipment and the learning curve needed to operate it effectively. Continuous training and updates on technology will also be necessary to achieve optimal performance in custom printing projects.

| Key Points | Description |

|---|---|

| What is UV DTF Printing? | UV DTF printing is a modern printing technique that uses UV light to cure inks on a special film, which is then transferred to various substrates using heat. This method enhances speed and efficiency of production. |

| High Durability | UV DTF transfers offer exceptional durability with prints being resistant to fading, scratching, and wear. This makes them ideal for long-lasting products, especially in high-use applications. |

| Eco-Friendly Options | Using UV DTF printing can reduce environmental impact as it utilizes inks that emit fewer volatile organic compounds (VOCs), aligning with sustainability trends in printing. |

| Versatility of Substrates | This printing method can be applied to a wide range of materials, including fabrics, plastics, metals, and wood, allowing businesses to diversify their products and target various markets. |

| Vibrant Colors and Fine Details | UV DTF technology excels in producing vibrant colors and intricate designs, making it an attractive option for artists and designers who require high-quality prints. |

| Market Trends and Outlook | There is a growing demand for UV DTF printing driven by the need for custom printing solutions. As adoption increases, advancements will likely enhance the technology further. |

| Challenges and Considerations | The transition to UV DTF printing can require significant initial investment and training. Companies must be prepared to address the learning curve and technology maintenance. |

Summary

UV DTF Transfers are revolutionizing the printing industry by providing high durability, eco-friendliness, versatility, and stunning visuals. As technological advancements unfold, this innovative printing process is not only meeting current demands but also shaping future trends in customization and sustainability. Embracing UV DTF technology allows businesses to thrive in a competitive marketplace that increasingly values creativity and environmental responsibility.