DTF transfers, or Direct-to-Film transfers, have emerged as a transformative technique in the custom apparel industry, allowing individuals to showcase their unique style with vivid and intricate designs. This innovative process involves printing high-definition images directly onto a specialized film before transferring them onto various fabric types, including cotton and polyester. With the right DTF printing tips, even beginners can achieve stunning results that grab attention. To ensure you select the ideal DTF transfer sizes for your projects, understanding key factors such as garment type and design dimensions is essential. Following best practices for DTF transfers not only enhances the visual appeal but also prolongs the life of your custom garments.

Direct-to-Film (DTF) transfers are revolutionizing the way designs are applied to clothing, offering endless possibilities for personalization and creativity. Often referred to as film transfer printing, this method utilizes high-quality prints that are transferred to textiles through heat and pressure, resulting in vibrant and durable designs. When embarking on a custom garment project, it’s imperative to consider alternative terms for DTF transfers, such as graphic transfers and film printing solutions. Knowing how to choose the right sizes for these transfers ensures that your designs not only stand out but are also proportioned appropriately for different apparel types. By mastering the nuances of the DTF process, you can create standout pieces that reflect personal style while adhering to recommended practices.

Understanding the Importance of DTF Transfer Sizes

When it comes to DTF transfers, understanding the right sizes is pivotal for achieving the desired look on various garments. The size of your DTF transfer can significantly impact how the design appears on clothing, making it crucial to carefully evaluate each garment’s dimensions. Larger DTF transfers can dominate the visual space of a t-shirt or hoodie, potentially overshadowing the garment itself, whereas smaller transfers might get lost on larger items, lacking the impact needed to attract attention.

Furthermore, garments like sports jerseys or fitted caps may demand specific sizing for their unique shapes. For example, jersey materials might be more forgiving with larger designs, while caps could benefit from minimalistic transfers to maintain a sleek appearance. Therefore, knowing how to choose DTF transfers based on the context of particular clothing items allows for optimized visual impact and quality.

Best Practices for DTF Transfers on Garments

When undertaking DTF printing, adhering to best practices ensures both the aesthetic appeal of your design and its longevity. One of the essential techniques is to maintain the correct aspect ratio when resizing designs for DTF transfers. This practice prevents unsightly distortions that can occur if artwork is stretched or compressed. Moreover, utilizing specialized software can enhance the resolution, preserving intricate details that are vital for vibrant, high-quality prints.

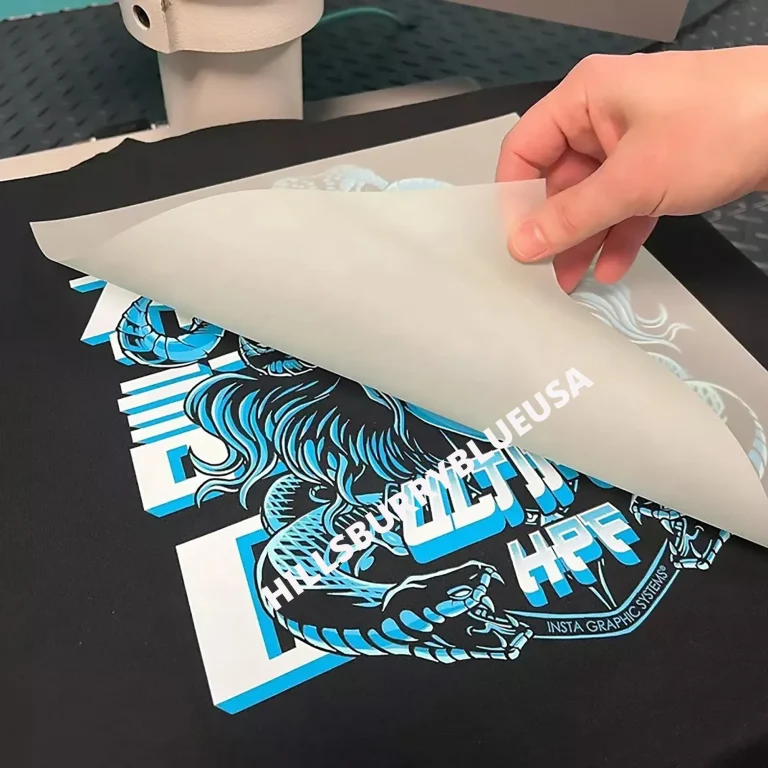

Heat settings and application timing are equally important. Transfers applied under incorrect temperatures or for too long may result in bleeding colors or uneven textures. Employing a heat press instead of an iron can elevate quality, providing consistent pressure and heat needed for optimal transfer adhesion. Following these best practices will help in ensuring that your DTF transfers not only look great but also stand the test of time.

Choosing the Right Fabric for DTF Transfers

While exploring DTF printing, another critical aspect is the type of fabric you choose for your custom apparel. Different materials offer varying compatibility with DTF transfers, which can ultimately affect the overall quality of the print. For instance, polyester fabrics are known for their superior adhesion properties and vibrant color output, making them excellent candidates for bold designs. On the other hand, while cotton can be used, it may not achieve the same brilliant appearance as polyester, leading to less satisfactory results.

Fabrics that combine both cotton and polyester often yield the best balance for custom printing. These blended fabrics allow for better transfer results, marrying the comfort of cotton with the stunning finish of polyester. It’s vital for creators to test their chosen fabric with DTF transfers to gauge compatibility and ensure that the artwork’s vibrancy is not compromised.

DTF Printing Tips for Stunning Results

To achieve stunning DTF prints, creators should be mindful of several DTF printing tips that enhance the finished product’s appearance. Start by ensuring that all graphics are created at a minimum resolution of 300 dpi to maintain clarity and detail when printed. Low-resolution designs can appear pixelated and unprofessional, detracting from the overall impact of the garment.

Additionally, consider the color profiles used in your design software. Using RGB colors can give broader vibrancy and life to the printed transfers compared to CMYK. Always conduct a test print to check colors and resolution before finalizing production, allowing for any adjustments that might be necessary for the best results.

What to Know About DTF Transfer Sizes

When deciding on DTF transfer sizes, it is essential to align the dimensions with the specific area of the garment where the design will be applied. For larger garments like hoodies, sizes can range from 10 to 15 inches, while smaller items, such as totes or caps, might only require designs of 3 to 5 inches. Understanding these size ranges ensures that the design remains proportionate and visually appealing.

In addition, keeping a close eye on the placement of the transfer is crucial. Centering larger designs on the front of shirts or hoodies adds balance, while smaller designs can be placed on sleeves or over the heart area. This strategic positioning can enhance the garment’s aesthetic, making the DTF transfer’s size even more significant.

Maximizing the Longevity of Your DTF Transfers

To ensure that your DTF transfers last long without fading or peeling, it is vital to follow care instructions closely. Washing garments inside out and in cold water with gentle detergents can significantly extend the life of the transfers. Additionally, avoiding bleach and fabric softeners can prevent degradation of the printed design, keeping it vibrant and intact.

Storing DTF-printed garments properly is just as important. Avoiding direct sunlight and excessive heat can prevent premature fading and curling of the transfers. Maintaining the right storage conditions not only preserves the print quality but also keeps the fabric in good shape, ensuring that your designs keep looking fresh and new.

Frequently Asked Questions

How do I choose the right DTF transfers for my garments?

Choosing the right DTF transfers involves understanding your garment type. For t-shirts, larger transfers of 10-12 inches work well, while hoodies benefit from 8-10 inch designs. Caps and small items typically require transfers around 3-5 inches. Always consider the garment’s dimensions to ensure a balanced look.

What sizes are available for DTF transfers?

DTF transfers come in various sizes to suit different garments. Small designs are typically 3-4 inches, medium prints range from 5-9 inches, and large designs can be 10-15 inches. Larger garments can accommodate bigger prints without overwhelming the overall design.

What are some tips for successful DTF printing?

For successful DTF printing, maintain the design’s aspect ratio and ensure a resolution of at least 300 dpi. Select suitable fabrics, with polyester yielding the best results. Perform tests with heat settings to find the optimal temperature and pressure for your specific transfer size.

Can DTF transfers be used on all types of fabrics?

While DTF transfers can be used on a variety of fabrics, they perform best on polyester. Cotton and blend fabrics can also work well, but the vibrancy may vary. It’s recommended to test your transfers on fabric samples to determine the best results.

What are the best practices for applying DTF transfers?

Best practices for applying DTF transfers include pre-testing heat settings on similar fabrics, keeping your designs at the recommended sizes, and ensuring that your heat press is properly calibrated. Follow manufacturer guidelines for heat and pressure settings tailored to your DTF transfer sizes.

How can I ensure the longevity of my DTF transfers?

To ensure the longevity of your DTF transfers, choose the appropriate size for your garment, use high-resolution artwork, and apply the transfer using the correct heat settings. Additionally, proper care during washing can help maintain the vibrancy and durability of the transfer.

| Key Factors | Details |

|---|---|

| Understanding DTF Transfers | DTF involves printing a design onto a special film, transferred to fabric with heat and pressure for vibrant, detailed results. |

| Garment Type Matters | T-shirts: 10-12″ designs, Hoodies: 8-10″, Caps: 3-5″ to suit aesthetics. |

| Maintain Aspect Ratios | Preserve ratio to avoid distortion. Use high-resolution design software. |

| General Print Size Guidelines | Small (3-4″), Medium (5-9″), Large (10-15″) depending on garment size. |

| Fabric Type | Polyester is best for DTF; blends are optimal, while cotton may be less vibrant. |

| Artwork Resolution | Aim for at least 300 dpi for clear, vibrant prints. |

| Heat Settings | Test heat settings on similar fabric before final application for best results. |

Summary

DTF transfers are crucial in the world of custom apparel and choosing the right size is essential for achieving visually striking designs that endure over time. By taking into account garment types, maintaining aspect ratios, ensuring high resolutions for artwork, and considering fabric compatibility, designers can create compelling pieces that stand out. Proper attention to these details enhances the quality and longevity of custom apparel, making every piece a unique expression of individuality.