DTF transfers, or Direct-to-Film printing, have revolutionized the textile industry, offering an innovative method for applying designs to fabric that combines durability with exceptional versatility. As apparel brands increasingly embrace this cutting-edge technology, it’s important to explore the DTF printing advantages that make it a standout choice among textile printing methods. This technique utilizes heat-activated adhesive on a specially prepared film to achieve vibrant and intricate prints, setting a new standard for quality and durability in garment decoration. Moreover, with its eco-friendly approach, DTF transfers align beautifully with the growing demand for sustainable printing solutions. In this blog post, we’ll unravel the intricacies of DTF transfer technology, examining its benefits, market trends, and recent advancements in the printing landscape.

Known in the industry as Direct-to-Film printing, DTF transfers represent a significant leap in fabric design technology. This approach, distinct from conventional methods like screen printing, employs a specialized process that involves printing designs onto a transfer film before applying them to textiles. By leveraging heat and adhesives, this process ensures high-quality prints that can adapt to a variety of fabrics and styles. The advantages of DTF printing not only cater to artistic preferences but also address the pressing need for eco-conscious solutions, marking it as a critical player in modern textile innovation. In the following sections, we will delve deeper into DTF’s transformative capabilities and its impact on garment production.

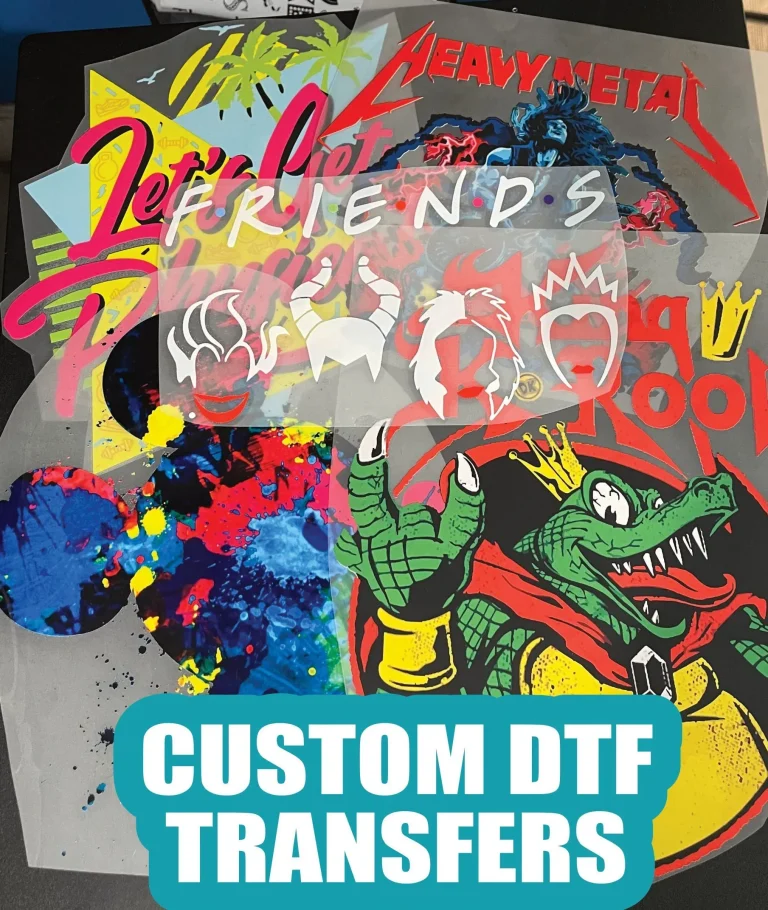

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology is revolutionizing the textile printing landscape. Unlike traditional methods that involve applying inks directly to fabric or utilizing screen printing techniques, DTF printing employs a special film that is coated with a heat-activated adhesive. This innovative process begins with a detailed digital design that is printed onto a transparent film, ensuring the final product captures even the finest details with impressive color accuracy. Once printed, the film is sprinkled with adhesive powder and subjected to heat, ensuring that when pressed onto fabric, the design adheres firmly, offering a robust and eye-catching finish.

DTF printing is not only about aesthetic appeal; it also boasts a user-friendly process that simplifies production for both large-scale manufacturers and small businesses. With minimal setup costs and reduced waste, DTF printing can cater to diverse fabric types, including cotton, polyester, and blends. This flexibility makes it an ideal choice for apparel brands looking to expand their offerings without significant upfront investments. As companies strive to meet market demands for unique and personalized designs, DTF transfer technology emerges as a vital tool, enabling them to stand out in a crowded marketplace.

The Advantages of DTF Printing

One of the most notable advantages of Direct-to-Film (DTF) printing is its incredible versatility in application across various fabric types. This technology can proficiently handle both light and dark materials, breaking boundaries where traditional textile methods often falter. This adaptability caters to a wider audience, allowing businesses to every garment requirement—from vibrant sportwear to elegant casual attire. Additionally, the ability to print on numerous substrates makes DTF an invaluable asset for custom garment decorators seeking flexibility in their offerings.

Cost-effectiveness is another key advantage of DTF printing technology. The process not only reduces setup costs compared to conventional screen printing but also minimizes the amount of ink and materials required for operation. For small businesses and startups, this translates into a more manageable startup investment and greater potential for profit. With DTF printing, companies can efficiently produce smaller batches of custom apparel without sacrificing quality, making it an attractive choice in today’s personalized fashion market.

Environmental Benefits of DTF Printing

As the push for sustainable printing solutions becomes more pronounced in the textile industry, DTF printing is emerging as a front-runner in environmentally-friendly practices. The DTF process utilizes significantly less water than traditional screen printing methods, leading to a reduced ecological footprint. Moreover, innovations in ink formulations are resulting in lower emissions of harmful volatile organic compounds (VOCs), making DTF printing a cleaner alternative that aligns with the growing consumer demand for sustainability.

Incorporating DTF printing can be a strategic move for businesses seeking to enhance their eco-conscious image. By adopting this technology, companies not only meet their operational needs but also respond to the increasing consumer preference for products that prioritize environmental impact. With sustainability at the forefront of many consumers’ minds, leveraging DTF printing technology can serve as a powerful marketing tool, helping brands build a loyal customer base focused on responsible production.

Current Trends in the DTF Printing Market

The current landscape of the DTF printing market is characterized by rapid adoption among small and medium-sized apparel manufacturers. With the trend towards custom designs gaining momentum, companies that incorporate DTF technology can quickly adapt to consumer demands for personalization. Recent surveys suggest that DTF printing is becoming the preferred choice for brands aiming to meet the needs of a fashion-forward audience while streamlining their production processes. As a result, businesses that embrace this technology can not only increase their product offerings but also enhance their market competitiveness.

Furthermore, advancements in DTF printing technology are propelling its popularity among manufacturers. Upgrades in printer design and improvements in ink formulations allow for higher precision, better color ranges, and overall enhanced performance. This evolution in technology positions DTF printing as a noteworthy competitor against other methods, especially Direct-to-Garment (DTG) printing, which has long been a staple in customized apparel. As technology continues to evolve, the future of DTF printing looks promising, filled with opportunities for innovation and market expansion.

Technological Advancements in DTF Printing

Technological developments within the DTF printing arena are continuously pushing the boundaries of what this method can achieve. Recent innovations in print head designs enable users to achieve finer details and more intricate patterns without compromising color quality. These advancements are critical for businesses aspiring to meet increasing consumer expectations for high-quality prints that are both visually striking and durable. As competition intensifies in the textile printing market, such improvements solidify DTF’s position as a leading choice for modern apparel companies.

Moreover, the evolution of ink formulations plays a vital role in the enhanced performance of DTF printing. New developments focus on creating inks that adhere better to various fabrics while maintaining vibrancy and wash durability. This ensures that DTF prints hold up over time, appealing to consumers who prioritize longevity in their apparel. As manufacturers continue to invest in research and development, the potential for DTF printing to lead the path in textile printing methods becomes increasingly evident, catering to an ever-evolving market.

Why Choose DTF Printing for Your Apparel Needs?

Choosing Direct-to-Film (DTF) printing can significantly benefit apparel businesses looking to enhance their production capabilities. The model allows for an easy transition between different printing demands, accommodating both small-scale orders and large production runs with equal efficiency. This adaptability is essential for brands seeking to keep pace with rapid fashion trends. By implementing DTF printing, businesses ensure they can respond quickly to customer requests while maintaining high-quality standards.

Additionally, DTF printing offers a unique value proposition by merging quality with affordability. The combination of lower setup costs and the ability to print intricate designs without the need for heavy equipment makes it an accessible option for budding entrepreneurs and established businesses alike. By choosing DTF printing, companies can engage with their consumer demographics in a more meaningful way, offering personalized and creative options that foster brand loyalty and repeat business.

Frequently Asked Questions

What are the benefits of using DTF transfers in textile printing?

DTF transfers offer numerous advantages over traditional textile printing methods. With Direct-to-Film printing, you get vibrant designs that can be applied to various fabric types including cotton and polyester. DTF printing is also cost-effective, making it ideal for small batch productions, and it boasts impressive durability, ensuring prints remain vibrant after multiple washes.

How does DTF printing technology differ from other textile printing methods?

Unlike traditional textile printing methods, DTF printing technology uses a film coated with heat-activated adhesive instead of printing directly onto the fabric. The design is first printed on a transparent film, which is then heat-pressed onto the fabric, allowing for intricate details and vibrant colors that can easily surpass other methods.

Are DTF transfers environmentally friendly compared to other printing options?

Yes, DTF transfers are considered more environmentally friendly than traditional methods like screen printing. The DTF printing process uses significantly less water and is designed to emit lower levels of harmful volatile organic compounds (VOCs), aligning with sustainable printing solutions highly sought after by eco-conscious consumers.

Can DTF transfers be used on all types of fabrics?

DTF transfers are versatile and can be applied to a wide variety of fabric types, including cotton, polyester, and blends. This adaptability makes DTF printing advantageous for different garment styles and colors, making it suitable for both light and dark materials.

What is the drying time for DTF transfers?

DTF transfers generally have a quick drying time due to the heat curing process involved in DTF printing. Once the design is heat-pressed onto the fabric, it adheres firmly, allowing for immediate use of the printed garment, typically requiring only a short cooling period before handling.

How do DTF printing advantages contribute to market trends in custom apparel?

The advantages of DTF printing, such as its cost-effectiveness, durability, and capability for intricate designs, contribute significantly to market trends in custom apparel. With the increasing demand for personalized designs, businesses that adopt DTF transfer technology can meet consumer needs rapidly while optimizing production efficiency.

| Key Features | Details |

|---|---|

| Printing Process | Involves printing on transparent film, curing with heat-activated adhesive, and applying to fabric using heat press. |

| Advantages Over Other Methods | Includes versatility for various fabrics, cost-effectiveness for smaller batches, and durability of prints. |

| Environmental Impact | Uses less water than screen printing and has lower VOC emissions, making it eco-friendlier. |

| Market Trends | Increasing adoption among small to medium-sized manufacturers to meet the demand for personalized apparel. |

| Technological Developments | Advancements in printer designs and ink formulations, enhancing detail and color range. |

Summary

DTF Transfers are revolutionizing the textile printing industry by combining cutting-edge technology with eco-friendly practices. This printing method allows for customized designs to be transferred onto various fabrics with remarkable durability and vibrancy, positioning DTF as a strong contender in the market. As more apparel brands adopt DTF printing, its advantages of versatility, cost-effectiveness, and reduced environmental impact are becoming increasingly recognized. The growing trend towards personalization in fashion further emphasizes the role of DTF Transfers in meeting modern consumer demands, making it an essential consideration for anyone in the apparel industry.