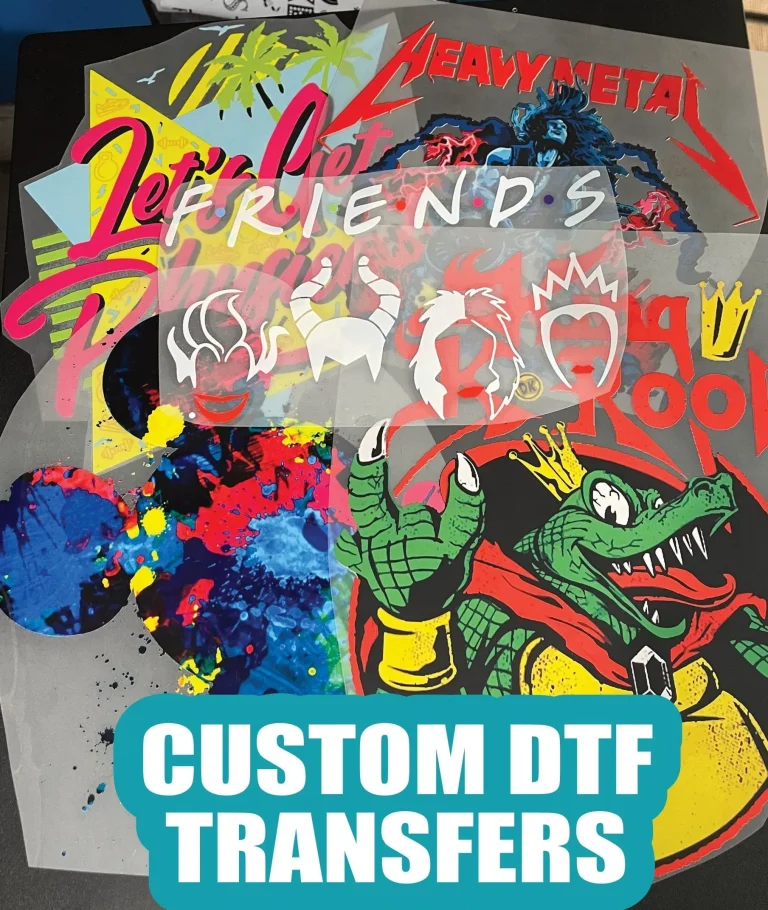

DTF transfers, or Direct-to-Film transfers, are at the forefront of modern apparel design technology, revolutionizing how intricate designs are applied to custom clothing. This innovative method uses high-quality images printed onto a specially coated film, enabling creators to achieve vibrant colors and detailed designs that stand out. As the demand for custom apparel rises, DTF printing has emerged as a go-to solution for designers eager to make their mark in the customized fashion industry. The advantages of sustainable printing with DTF technology not only enhance the quality of the final product but also reduce waste and support eco-friendly practices. With its user-friendly application, DTF transfers open doors for both seasoned creators and newcomers, fostering creativity in the world of fashion like never before.

Direct-to-Film (DTF) printing, often referred to in various terms such as film transfer technology or custom film applications, is quickly gaining traction among designers and entrepreneurs. This pioneering technique allows for seamless application of high-resolution imagery onto fabrics, setting the stage for versatile and personalized apparel options. As the apparel industry grows increasingly competitive, leveraging innovative technology like film transfer printing can provide a significant edge. Furthermore, with its focus on sustainable printing practices, it appeals to environmentally conscious consumers seeking unique clothing items. The evolution of apparel design technology has made custom clothing more accessible, encouraging designers to embrace this efficient and creative method.

Understanding the Mechanics of DTF Transfers

Direct-to-Film (DTF) transfers have become a game-changer in the world of custom apparel. This innovative printing technique begins with the careful creation of high-resolution designs using graphic software, where users can unleash their creativity without the limitations posed by traditional printing methods. Significantly, it allows designers to incorporate intricate details and a wide range of colors. By embracing DTF, artists can produce designs that seamlessly reflect their unique style and vision, ultimately elevating the level of customization available in the apparel industry.

What sets DTF apart is its user-friendly nature, making it accessible even to those with minimal technical skills. With the advancements in apparel design technology, direct-to-film printing systems often include guided interfaces, ensuring that the user experience is smooth and intuitive. This democratization of printing technology paves the way for aspiring entrepreneurs and hobbyists to explore the potential of creating custom clothing without needing years of expertise or expensive equipment.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel?

DTF transfers, or Direct-to-Film transfers, are a printing method where high-quality images are printed onto a special film and then heat-pressed onto fabric. This technology allows for vibrant colors and intricate designs, making it ideal for custom apparel production.

What are the advantages of using DTF transfers for sustainable printing?

DTF transfers offer numerous advantages for sustainable printing. This method minimizes waste by allowing on-demand printing, reduces the need for extensive setup typical in traditional methods, and uses eco-friendly water-based inks, making it a great choice for environmentally conscious apparel designers.

How does DTF printing compare to traditional screen printing for apparel design?

Compared to traditional screen printing, DTF printing is more cost-effective for small runs, allows for more complex designs with vivid colors, and eliminates the need for screens. DTF transfers also cater to the demand for quick customization in custom clothing.

Can DTF transfers be used on various fabrics and what are the limitations?

Yes, DTF transfers can be applied to a variety of fabrics, including cotton, polyester, and blends. However, it’s important to note that the quality of the final print may vary depending on the fabric’s composition and the application process.

What should I look for when choosing a DTF printer for custom clothing production?

When selecting a DTF printer, consider factors such as print quality, compatibility with inks and films, and the quality of customer support provided. High-quality printers designed specifically for DTF applications ensure vibrant and detailed prints for your custom apparel.

How can DTF transfers enhance versatility in apparel design technology?

DTF transfers enhance versatility in apparel design technology by offering the ability to produce a wide range of designs quickly and with minimal setup. This flexibility enables designers to experiment with various styles and cater to trends in the custom clothing market effectively.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF (Direct-to-Film) transfers enable high-quality, intricate designs to be printed on fabrics, streamlining production for apparel industries. |

| What are DTF Transfers? | DTF involves printing vibrant images on coated film, which are then heat-pressed onto fabrics for a durable bond. |

| Advantages of DTF Transfers | High-quality output, cost-effectiveness, eco-friendly practices, catering to market trends, and ease of use. |

| How DTF Transfers Work | 1. Design in graphic software 2. Print on transfer film 3. Heat press to fabric 4. Ready for wear. |

| Choosing the Right DTF Printer | Look for printer quality, compatible inks and films, and strong user support. |

Summary

DTF transfers are at the forefront of innovative apparel production, allowing designers and entrepreneurs to turn their unique ideas into reality with stunning results. By utilizing Direct-to-Film technology, the fashion industry is not only enhancing the quality of garments but also embracing sustainability and customization. This approach is particularly appealing to modern consumers who desire individuality in their clothing. As the DTF transfer process becomes more widely adopted, those involved in apparel design will find that it provides the flexibility and efficiency needed to thrive in today’s fast-paced market. Adopting DTF technology can elevate your brand and align it with the growing demand for personalized experiences in the fashion sector.