In the dynamic arena of custom apparel, DTF transfers stand out as a revolutionary printing method that is rapidly gaining traction among businesses and fashion enthusiasts alike. Direct to Film (DTF) transfer printing not only delivers stunning results but also caters to the diverse needs of consumers with its impressive adaptability across various fabric types. This innovative technology enables the creation of vibrant apparel designs that capture attention and showcase intricate details, making it an advantageous choice for brands eager to differentiate themselves in a competitive market. Furthermore, the DTF printing benefits extend beyond mere aesthetics; they also include cost-effectiveness and sustainability, appealing to eco-conscious consumers seeking responsible options. Join us as we explore the top five benefits of utilizing DTF transfers for your custom apparel needs, a solution that harmonizes quality with innovation.

When it comes to the realm of apparel printing, Direct to Film transfers have emerged as a compelling alternative to traditional methods. Often heralded for their versatility and ability to produce vibrant prints, DTF technology facilitates application across a wide range of fabrics. This form of transfer printing has become a game changer for those looking to produce custom garments with a focus on quality and detail. Additionally, businesses can benefit from lower production costs and the eco-friendly initiatives that DTF printing embodies, aligning with the growing demand for sustainable practices in the fashion industry. As we delve further into the advantages of this innovative printing technique, it becomes clear that DTF transfers are revolutionizing the way custom apparel is designed and produced.

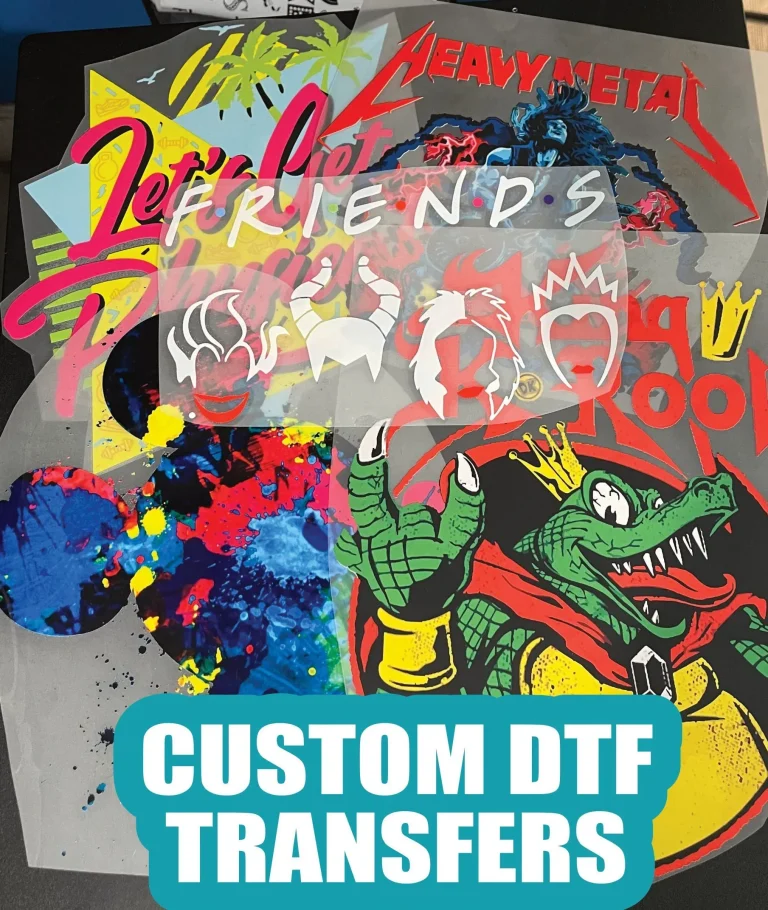

The Versatility of DTF Transfers in Custom Apparel

DTF transfers exhibit remarkable versatility, allowing them to be used across a wide range of fabric types, including cotton, polyester, and complex blends. This adaptability makes DTF the preferred choice for custom apparel businesses seeking to cater to diverse customer demands. For instance, whether a client is looking for vibrant designs on sports jerseys or intricate graphics on fashion statements, DTF transfers can easily accommodate these requests. This flexibility not only broadens the product offerings for businesses but also enhances customer satisfaction, as the quality and variety of garments can be matched to audiences with differing tastes.

Additionally, the ability of DTF transfers to adhere to both light and dark fabrics allows for a unified product line regardless of the color scheme. This means that businesses can experiment with various styles and designs while ensuring high-quality results across the board. As a result, apparel brands are empowered to innovate their collections continually, making it an excellent time for businesses to embrace DTF technology and explore the extensive possibilities it offers in custom apparel production.

Vibrant Designs through DTF Printing

In the world of custom apparel, the visual impact of a design is paramount, and DTF printing excels in this domain by allowing for rich colors and sharp details. Unlike traditional printing methods, DTF enables the application of vibrant inks that produce stunning, high-resolution images on garments. This means brands can achieve striking graphics that not only stand out on the shelf but also attract customer interest in a crowded market. The technology behind DTF ensures that colors remain consistent and do not fade, delivering a level of quality that is essential for creating memorable and lasting impressions.

Moreover, DTF printing allows designers the freedom to create complex designs that include gradients and multiple colors without sacrificing detail. This capability is crucial for businesses looking to create exclusive and eye-catching apparel that represents their brand’s unique identity. As such, companies can leverage this strength not just to attract customers but also to foster a strong brand presence in the market, using vibrant designs as a cornerstone of their product offerings.

The Durability of DTF Transfers

The longevity and durability of prints are critical factors in ensuring customer satisfaction in the custom apparel brand landscape, and DTF transfers stand out for their robust nature. Unlike other printing methods that may experience issues such as cracking or peeling over time, DTF prints maintain their integrity even after numerous washes. This characteristic is essential for brands that prioritize quality, as it builds customer trust and can significantly reduce return rates due to product dissatisfaction. Customers increasingly seek garments that not only look great but also hold up to everyday use, making durability an essential selling point.

Furthermore, the durability of DTF transfers can be attributed to the advanced adhesive technology used during the transfer process. The prints adhere to the fabric at a molecular level, forming a tough bond that withstands everyday wear and tear. This results in apparel that looks new longer, keeping customers happy and enhancing the brand’s reputation for quality. Companies that invest in DTF transfers reap the rewards of lower production costs associated with returns and reprints, allowing them to focus on creativity and product development.

Cost-Efficiency in DTF Printing

Cost-effectiveness is a crucial concern for businesses in the custom apparel industry, especially for small to medium enterprises. DTF transfers provide a financially viable solution for producing custom designs in smaller quantities without the significant upfront costs associated with methods like traditional screen printing. By removing the need for physical screens, the DTF printing process allows brands to offer personalized apparel at competitive prices while maintaining high-quality outputs. This flexibility is attractive to customers looking for custom orders without breaking the bank.

In addition to short runs, DTF technology allows for faster setup and production times, ensuring that businesses can respond quickly to market trends and consumer demands. This agility is vital for brand survival in a fast-paced retail environment, enabling companies to seize opportunities and maintain a steady flow of fresh stock. As a result, brands that utilize DTF printing can also take pride in their ability to meet urgent orders, further establishing their position as reliable providers in the custom apparel sector.

Eco-Friendly Advantages of DTF Printing

In a world increasingly focused on sustainability, DTF transfers distinguish themselves as an eco-friendly option in the realm of custom apparel printing. Utilizing water-based inks rather than harmful solvent-based alternatives, DTF technology aligns with the growing consumer demand for green practices in production. This allows businesses to appeal to environmentally conscious customers seeking products that support their values. The use of sustainable materials in DTF printing can significantly enhance a brand’s image as socially responsible, creating a powerful marketing point that resonates with modern consumers.

Additionally, the reduced waste associated with the DTF printing process contributes further to its eco-friendliness. Unlike traditional printing, where excess materials can lead to significant waste, DTF’s streamlined approach minimizes the environmental impact of clothing production. Brands that adopt DTF technology can showcase their commitment to sustainability, potentially capturing a wider audience and fostering loyalty among consumers who prioritize responsible purchasing decisions. As environmentally friendly practices become a standard expectation, leveraging DTF printing helps businesses stay ahead of the curve while contributing positively to the planet.

The Future of Custom Apparel with DTF Transfers

The landscape of custom apparel is rapidly changing, and DTF transfers are leading this transformation with innovative technology. As businesses and consumers alike recognize the significant benefits of versatility, quality, and sustainability, DTF printing is positioned to become the dominant method in the apparel industry. With advancements in printing technology and materials, the potential for even more creative and high-quality designs continues to grow, opening endless opportunities for brands to explore new frontiers.

In this evolving market, businesses that embrace DTF transfers not only position themselves as cutting-edge but also build a strong foundation for future growth. By staying attuned to trends in custom apparel and continually innovating product offerings, brands can maintain their competitive edge and attract new customers. The forward momentum of DTF printing technology is set to redefine what is possible in custom apparel, enabling businesses to realize their creative visions while meeting the demands of an increasingly discerning consumer base.

Frequently Asked Questions

What are DTF transfers and how are they used in custom apparel?

DTF transfers, or Direct to Film transfers, are a cutting-edge printing method used in custom apparel production. They involve printing designs onto a special film that can then be transferred onto various fabrics. This technique allows apparel businesses to offer vibrant, high-quality designs on a wide range of garments, from athletic wear to casual outfits.

What are the benefits of choosing DTF printing for custom apparel?

DTF printing offers several benefits for custom apparel, including vibrant colors and intricate details, durability against wear and tear, and versatility in fabric compatibility. Additionally, it provides lower production costs compared to traditional methods, making it ideal for small to medium-sized businesses looking to meet specific customer needs without sacrificing quality.

Is DTF printing a sustainable option for custom apparel production?

Yes, DTF printing is considered a sustainable option as it often uses water-based inks that are less harmful to the environment than traditional inks like plastisol. Brands that integrate eco-friendly DTF transfers into their production can appeal to the growing market of environmentally conscious consumers.

How do DTF transfers compare to traditional apparel printing techniques?

DTF transfers stand out against traditional printing techniques like screen printing by offering lower setup costs, quicker turnarounds for short runs, and enhanced design capabilities that allow for vibrant colors and finer details. Unlike heat transfer vinyl, DTF prints are also more durable, resisting cracking and fading over time.

What types of fabrics are compatible with DTF transfers?

DTF transfers can be applied to a variety of fabrics, including cotton, polyester, blends, and more. This versatility makes DTF printing suitable for a wide range of custom apparel, catering to different customer preferences and garment styles.

Can small businesses benefit from using DTF transfers in their custom apparel lines?

Absolutely! Small businesses can significantly benefit from DTF transfers due to their lower production costs and efficiency in processing custom orders. This method allows them to provide high-quality, personalized apparel to customers while maintaining competitive pricing and adapting quickly to market demands.

| Benefit | Description |

|---|---|

| Versatile Fabric Compatibility | Adheres to a variety of fabrics like cotton and polyester, enabling customization across multiple garment types. |

| Vibrant Colors and Detail | Produces eye-catching designs with rich colors and intricate details that stand out in the market. |

| Durability | Offers longevity against cracking, fading, and peeling, making apparel last longer after repeated wear. |

| Lower Production Costs | More affordable for short runs and custom orders compared to traditional screen printing. |

| Eco-Friendly Options | Utilizes water-based inks that are less harmful to the environment, appealing to eco-conscious consumers. |

Summary

DTF transfers have become a transformative solution in the custom apparel industry, offering multiple benefits that cater to the evolving demands of consumers. This innovative method allows businesses to create more personalized products, enhance brand visibility through vibrant designs, ensure durability that customers appreciate, reduce production costs, and embrace eco-friendly practices. As the market for custom apparel continues to grow, adopting DTF transfers will not only improve product offerings but will also strengthen customer loyalty, positioning brands advantageously for future success.