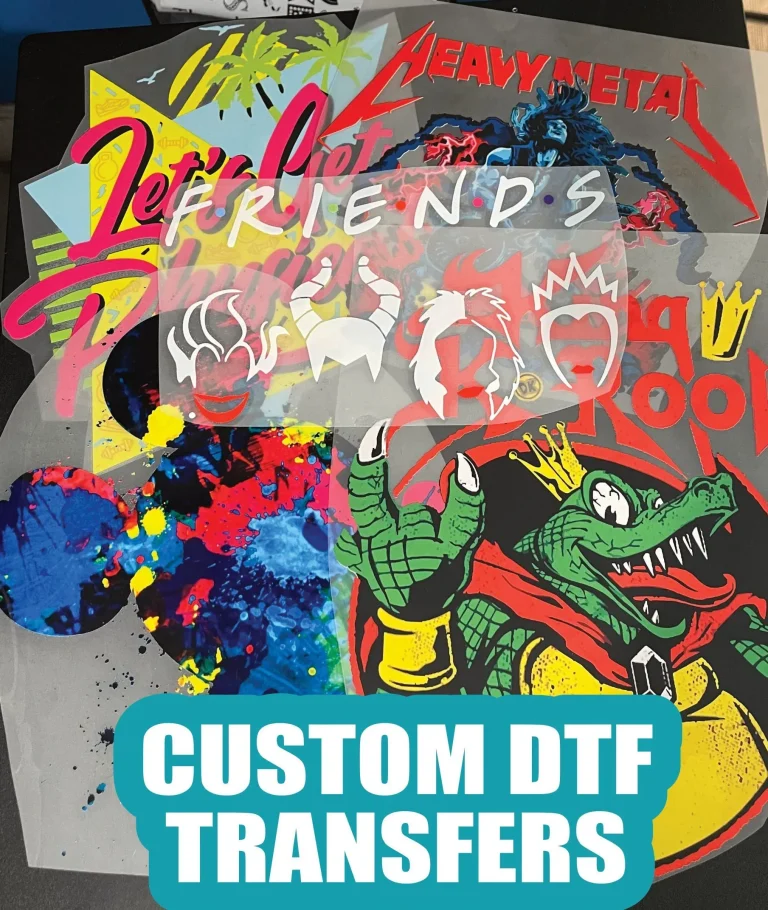

DTF transfers, or Direct to Film transfers, represent a groundbreaking leap in the realm of custom apparel printing. Leveraging advanced DTF printing technology, this method allows users to create vividly detailed prints that can be applied to a wide range of fabrics. Not only do DTF transfers deliver exceptional color vibrancy, but they also ensure durability, making them an attractive option for both entrepreneurs and crafting enthusiasts. In this guide, we’ll explore the various applications of DTF transfers, dissecting the significance of size in the printing process and offering expert tips on maximizing your results. Whether you’re looking to make a statement with custom apparel or learn the ins and outs of DTF transfer printing, understanding the fundamentals is essential for success in the industry.

When we talk about film transfers for apparel, we’re delving into innovative techniques that have redefined how designs are applied to fabric. Known variably as film printing and transfer technology, this method allows for a seamless and professional finish on garments, expanding the creative possibilities for both designers and businesses. The ease of DTF transfer applications makes it a preferred choice for producing everything from bespoke clothing lines to promotional merchandise. Understanding the nuances of sizing and design intricacy in this process is crucial for anyone involved in custom fabric designs. This article serves as a comprehensive DTF transfer printing guide, offering insights that will elevate your printing endeavors.

Understanding DTF Transfers: A Primer on Size and Quality

Direct to Film (DTF) transfers have revolutionized the realm of custom apparel, offering a unique method for applying intricate designs onto garments. The significance of understanding the size parameters associated with DTF transfers cannot be overstated, as it directly influences both the aesthetic and functional outcomes of the printing process. With a variety of sizing options available, users must carefully consider the size of DTF transfers to ensure that their designs maintain clarity and vibrancy when applied to different fabrics.

For example, smaller logos or detailed images can work effectively on various surface types but may require resizing when transitioning to larger apparel pieces. This resizing must be handled delicately to prevent loss of detail, which can occur if the original design is simply stretched without considering resolution. Thus, understanding print size options becomes essential for achieving high-quality results in custom apparel.

The Role of Material Compatibility in DTF Transfers

Material compatibility is critical when determining the appropriate size of DTF transfers. Different fabrics interact with printed designs in unique ways; for example, cotton and polyester may react differently to larger and more colorful prints. Understanding which materials are optimal for DTF transfers can prevent mishaps like bubbling or fading, especially when applying oversized designs. In general, heavier fabrics can handle larger transfers better without compromising adherence or print quality.

Conversely, lighter or thinner materials often necessitate smaller transfer sizes to maintain the integrity of the print. Therefore, choosing the right size in accordance with the fabric type is not only about visual appeal but also about ensuring durability and quality that will stand the test of time.

Maximizing Print Quality with Effective DTF Scaling

Scaling designs appropriately for DTF transfers is an essential skill for anyone interested in producing high-quality prints. Utilizing advanced graphic design tools allows users to resize their creations without losing detail, thereby enhancing the transfer’s overall quality. Correct scaling also considers the size of the garment and the visual dynamics of the design. For larger designs, maintaining the aspect ratio is crucial to ensure the print retains its intended look when transferred to fabric.

Furthermore, effective scaling can help avoid unnecessary waste of materials and ensure that the end product is both aesthetically pleasing and financially viable. By optimizing the dimensioning of DTF transfers, businesses can improve their product offerings while maximizing their return on investment in custom apparel.

Heat Application Techniques for Optimal DTF Transfer Results

The application of heat during the DTF transfer process is paramount, particularly concerning the size and complexity of the designs. To achieve the best results when applying larger transfers, it is important to manage temperature and pressure settings accurately. An even distribution of heat and pressure is critical to prevent issues like peeling or color fading after the transfer is applied.

Adjustment in time settings is equally important, especially for oversized designs. Each application may require longer heat exposure to ensure that the film adheres appropriately to the fabric. This detailed attention during the heat application stage can mean the difference between a successful transfer and one that fails to meet quality standards.

Understanding Cost Factors Associated with DTF Transfer Sizes

When considering DTF transfers, it is equally important to assess the cost implications linked to different transfer sizes. Larger designs typically require more materials, leading to increased expenses for both films and inks. This financial consideration is crucial for businesses that aim to maintain profitability while providing high-quality custom apparel options.

Conducting a cost-benefit analysis is essential before committing to larger transfer sizes. Businesses should gauge whether the potential for higher visual impact and design complexity outweighs the associated costs. By strategically selecting transfer sizes that balance affordability with quality, businesses can optimize their custom apparel offerings.

Innovative Trends in DTF Printing Technology

The DTF printing landscape continues to evolve, bringing forth innovation that enhances the quality and applicability of transfers. Recent advancements focus on refining the ink composition and printing techniques, which ultimately allows for greater detail and size options without compromising on quality. This technological evolution enables businesses to offer a wider variety of custom apparel options, catering to diverse consumer preferences.

Additionally, as sustainability gains traction in the industry, many companies are shifting toward eco-friendly materials and processes. These innovations not only enhance print quality but also align with the growing demand for environmentally responsible manufacturing practices, paving the way for the future of DTF transfers.

Frequently Asked Questions

What are the size options for DTF transfers?

DTF transfers offer a variety of size options, accommodating everything from small logos to large graphic designs. Choosing the right size depends on the fabric type and the intricacy of the design—this ensures that details are maintained and colors remain vibrant during the transfer process.

How does DTF printing technology accommodate different design sizes?

DTF printing technology allows seamless adjustment of design sizes. High-quality graphics software can help resize images while retaining resolution. It’s essential to match the print size with the garment’s specifications to maintain clarity and vibrancy in the final product.

What types of fabrics are compatible with DTF transfer applications?

DTF transfer applications work effectively on various materials, including cotton, polyester, and blends. However, the size of the transfer should be adjusted according to the fabric—larger designs may cause bubbling on thinner materials unless applied correctly.

How can I ensure the best results with custom apparel DTF transfers?

To achieve the best results with custom apparel DTF transfers, select an appropriate size based on the garment and fabric type. Additionally, it’s important to adjust the heat press settings—temperature, pressure, and time—to fit larger designs, ensuring complete adhesion and durability.

What are the cost considerations when choosing sizes for DTF transfers?

Cost considerations are vital when working with DTF transfers. Larger prints typically require more materials and inks, which can drive up costs. Businesses should analyze the cost-effectiveness of size options, balancing potential pricing with design complexity to maintain profitability.

What recent developments in DTF printing technology impact the size of transfers?

Recent developments in DTF printing technology, such as improved inks and advanced printing processes, have enhanced resolution and quality. These innovations allow for larger and more complex designs without sacrificing vibrancy, making it easier to accommodate various size needs in DTF transfers.

| Key Aspect | Description |

|---|---|

| Introduction to DTF Transfers | DTF printing technology allows for vibrant designs on various fabrics, enhancing the custom apparel market. |

| Importance of Size | Size affects print quality; different garments require different sizing to showcase designs effectively. |

| Print Size Options | Various sizes accommodate everything from small logos to large artworks, critical for detail preservation. |

| Scaling Designs | Proper software helps resize without losing resolution, essential for matching garment specifications. |

| Material Compatibility | Different fabrics behave differently with DTF transfers, impacting size selection. |

| Printing Technology | Utilizing advanced printers with features like white ink can enhance vibrancy for larger designs. |

| Heat Press Specifications | Temperature, pressure, and application time are critical for successfully larger transfers. |

| Cost Implications | Larger transfers can increase material costs, necessitating a cost-benefit analysis for businesses. |

| Recent Developments | Innovations in inks and sustainable practices are shaping future DTF printing. |

Summary

DTF transfers are revolutionizing the custom apparel industry by offering a flexible and vivid printing option. When utilizing DTF transfers, understanding the implications of design size is crucial. Each garment type can affect how your design will be displayed, emphasizing the importance of selecting the right print dimensions. Moreover, the compatibility of fabric types can lead to varying results in transfer effectiveness and durability. With advancements in printing technology and a growing emphasis on sustainability, the future of DTF transfers looks promising. This comprehensive understanding allows creators to maximize potential and engage in profitable custom apparel ventures.