In the dynamic realm of custom apparel, UV DTF transfers are revolutionizing how designs come to life. This innovative printing technique merges versatility with high-quality prints, enabling brands to create stunning visuals that resonate with customers. Beyond merely enhancing aesthetics, the benefits of DTF printing extend to eco-friendly printing options, which appeal to the growing consumer base focused on sustainability. Fast production times further amplify its attractiveness, granting businesses the ability to meet market demands swiftly without sacrificing quality. As the apparel industry continues to evolve, adopting UV DTF transfers could be the key to unlocking creative potential and setting a brand apart from the competition.

When exploring advanced methodologies in custom apparel, one may encounter Direct to Film (DTF) printing, a technology that significantly enhances fabric decoration. This printing process is characterized by its ability to deliver vibrant and detailed finishes, whether on soft textiles or hard surfaces, ensuring a diverse range of applications. In addition to high-quality outputs, businesses are increasingly drawn to the eco-conscious choices available in DTF printing, which align with contemporary consumer values. Coupled with rapid turnaround times, this printing method is reshaping the landscape of apparel production, making it a paradigm of efficiency and creativity. By embracing DTF, brands position themselves as leaders in sustainability and innovation within a competitive market.

The Advantages of UV DTF Transfers for Custom Apparel

UV DTF transfers stand out as a transformative solution for custom apparel, offering numerous advantages that are hard to ignore. The technology allows for high-resolution prints that can capture intricate designs and vibrant colors, a benefit that appeals to both brands and consumers alike. As fashion evolves, the need for top-notch quality in apparel printing cannot be overstated. Brands using UV DTF can expect to differentiate themselves with prints that not only look aesthetically pleasing but also remain durable over time, making them an ideal choice for high-quality custom garments.

Aside from visual appeal, UV DTF transfers provide an efficiency that traditional printing methods often lack. With production processes streamlined through automation, brands can quickly meet customer demands without sacrificing quality. This duality of superior quality and operational efficiency places UV DTF technology at the forefront of custom printing solutions, giving businesses the competitive edge they need in a saturated market.

Exploring the Versatility of UV DTF Transfers

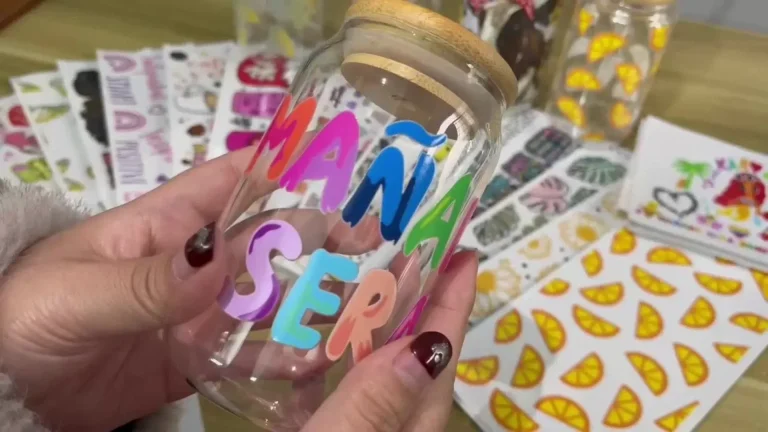

One of the defining traits of UV DTF transfers is their versatility across various materials. Unlike traditional screen printing that often restricts options to cotton and polyester, UV DTF can be effectively used on a plethora of surfaces including leather, denim, and even hard substrates. This opens a world of possibilities for brands looking to diversify their product offerings and create unique promotional items. Custom apparel can now extend beyond mere clothing to include accessories, bags, and specialized merchandise, enticing a broader customer base.

Customer feedback consistently underscores the versatility offered by UV DTF technology, showing that brands can confidently tackle creative projects without worrying about material limitations. This flexibility not only fuels creativity but also allows businesses to cater to niche markets, exploring unique product launches that traditional methods simply cannot accommodate.

Eco-Friendly Printing with UV DTF Technology

As society becomes increasingly environmentally conscious, the printing industry is taking strides towards sustainable practices. UV DTF transfers utilize water-based inks, presenting a more eco-friendly alternative to conventional inks that often contain harmful chemicals. By adopting such methods, businesses can significantly reduce their carbon footprint while appealing to eco-aware consumers. This environmentally responsible approach can enhance brand reputation and customer loyalty, making eco-friendly printing more than just a trend—it’s a business necessity.

Furthermore, the durability of UV DTF prints means that fewer resources are wasted over time. Brands that prioritize sustainability can attract conscientious consumers looking to support companies with a clear commitment to reducing environmental impact. As a result, transitioning to UV DTF technology is not only beneficial for the planet, but it represents a strategic business move that aligns with current consumer values.

Fast Production Times with UV DTF Prints

In the realm of custom apparel, speed is essential. UV DTF transfers excel in this domain by significantly reducing production times compared to traditional printing methods. The technology leverages ultraviolet light to cure prints almost instantaneously, allowing for rapid turnaround on orders. This efficiency not only meets the demands of a fast-paced market but also increases customer satisfaction, as clients appreciate receiving their orders quicker.

Moreover, these fast production capabilities empower businesses to take on larger volumes of custom orders, enhancing their overall operational efficiency. Brands can become known for their quick service, ensuring repeat customers and inviting new ones to explore their offerings. As markets shift rapidly, the ability to deliver timely products can set a company apart in the competitive landscape of custom apparel.

Cost-Effectiveness of UV DTF Printing

The initial investment in UV DTF technology may seem significant, but businesses quickly realize its cost-effectiveness as they scale their operations. The more units produced, the lower the cost per item, allowing for better profit margins over time. As production volume increases, the durability and high quality of UV DTF prints diminish the need for reprints, further saving on material and labor costs.

In addition, the longevity of UV DTF prints means that customers enjoy quality products that last, reducing the chances of returns or unsatisfied clients. This aspect not only reinforces brand trust but also leads to healthier financial outcomes for businesses. Investing in UV DTF technology, therefore, is not just about upgrading equipment; it’s about securing a more sustainable and profitable future in the custom apparel industry.

The Future of Custom Apparel with UV DTF Transfers

As we look to the future, UV DTF transfers are positioned to lead the next wave of innovation in custom apparel. The combination of high-quality prints, eco-friendly materials, quick production, and cost efficiency makes this technology an attractive option for brands aiming to stay ahead in a competitive market. By embracing UV DTF transfers, businesses not only cater to immediate demands but also align themselves with the global shift towards sustainability and quality.

The potential for creativity with UV DTF transfers is boundless, allowing brands to explore new design possibilities and reach diverse customer bases. As technology evolves and consumers continue to prioritize quality and environmental impact, those who plan to incorporate UV DTF printing into their strategies are sure to thrive, cementing their place as innovators in the custom apparel landscape.

Frequently Asked Questions

What are the main benefits of using UV DTF transfers for custom apparel?

UV DTF transfers offer several advantages for custom apparel businesses, including high print quality, versatility on various materials, eco-friendly options, faster production times, and cost-effectiveness. These benefits help brands create stunning designs while optimizing efficiency and sustainability.

How does UV DTF printing compare to traditional screen printing?

UV DTF printing stands out with its superior high-quality prints and detail, particularly for intricate designs. Unlike traditional screen printing, it allows for vibrant colors and sharp imagery on various fabric types, making it an ideal choice for today’s competitive custom apparel market.

Is UV DTF printing an eco-friendly option for custom apparel?

Yes, UV DTF printing is considered eco-friendly because many of the inks used are water-based and produce lower harmful emissions compared to conventional inks. This sustainable approach attracts environmentally-conscious consumers and enhances a brand’s image.

How quickly can businesses produce custom apparel using UV DTF transfers?

UV DTF transfers significantly reduce production times compared to traditional methods. The UV curing process is quicker, enabling businesses to fulfill customer orders more efficiently and improve overall operational speed, which is crucial in the fast-paced custom apparel industry.

What types of materials can UV DTF transfers be applied to?

UV DTF transfers are versatile and can be applied to a wide array of materials, including cotton, polyester, leather, and even hard surfaces. This allows businesses to expand their offerings in custom apparel and promotional items.

How does the cost-effectiveness of UV DTF printing benefit custom apparel businesses?

UV DTF printing proves to be cost-effective since the cost per unit decreases with larger batch sizes. Additionally, the durability and high quality of UV DTF prints lead to less need for reprints, ultimately saving businesses material and labor costs in the long run.

| Key Benefits of UV DTF Transfers | Description | |

|---|---|---|

| 1. High Print Quality and Detail | Delivers intricate designs and vibrant colors with superior image sharpness. | |

| 2. Versatility on Different Materials | Can be applied to cotton, polyester, leather, and hard surfaces, enabling diverse projects. | |

| 3. Eco-Friendly Options | Utilizes water-based inks that reduce harmful emissions and appeal to environmentally-conscious consumers. | |

| 4. Faster Production Times | Curing with UV light expedites the printing process, enhancing operational efficiency. | |

| 5. Cost-Effectiveness | Initial costs lower over time with increased batch sizes, improving profit margins. | |

Summary

UV DTF transfers have revolutionized the custom apparel industry by combining high-quality output with versatility and sustainability. This innovative printing technology meets the diverse needs of businesses while providing exceptional results across various materials. The eco-friendly nature of UV DTF inks resonates with today’s environmentally aware consumers, enhancing brand image. Moreover, the efficiency and cost-effectiveness of this method allow brands to maintain competitive pricing and quick turnaround times. Businesses that embrace UV DTF transfers can not only fulfill current consumer demands but also secure a prosperous future in the marketplace.