DTF transfers, or Direct-to-Film transfers, have taken the custom apparel market by storm, offering a new level of versatility in high-quality prints. These innovative transfers allow for detailed designs and rich colors that can effectively elevate any garment, making them a favorite among fashion enthusiasts and professionals alike. However, one aspect that plays a significant role in the success of DTF printing is the size of the transfer itself, which can dramatically influence the overall outcome. Whether it’s the clarity of intricate patterns or the durability of oversized DTF transfers, understanding the impact of size is essential for both new and experienced users. In this guide, we will delve deeper into how different transfer sizes affect print quality and the important considerations to keep in mind when embarking on a DTF printing project.

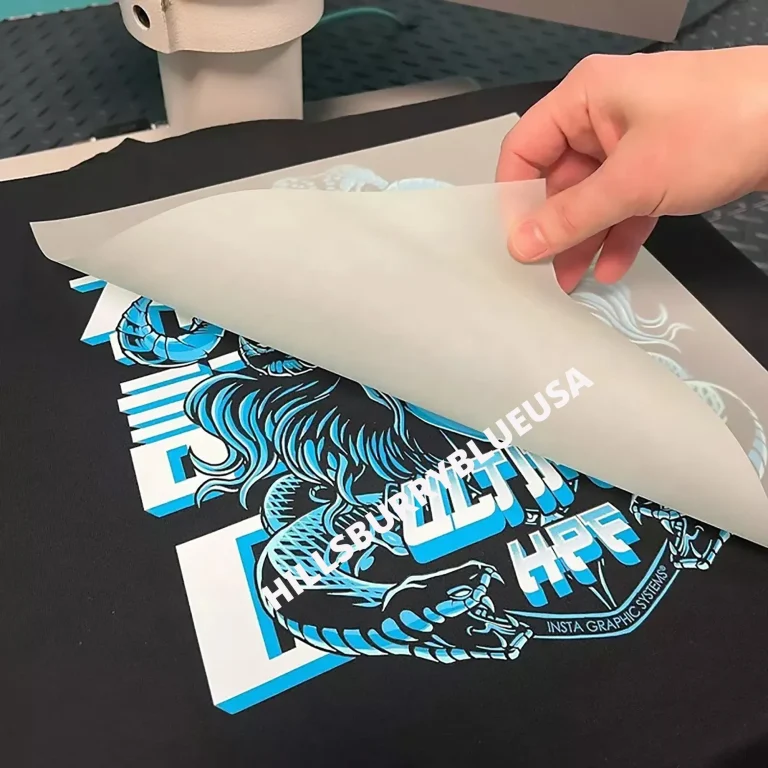

Also referred to as Direct-to-Film printing, this method of custom apparel printing utilizes heat transfer technology to apply vibrant designs onto various fabric types. The beauty of this technique lies not only in its capability to print complex images but also in the flexibility it offers in terms of transfer size. Whether you are looking to create small logos or expansive prints that cover a larger area, each size has its unique impact on the final product quality. By analyzing how design size influences DTF transfer quality, manufacturers and hobbyists alike can make informed decisions that lead to stunning results. In this article, we will explore the nuances of DTF printing, emphasizing the importance of adapting transfer sizes to meet consumer demands and preferences.

How Size Affects DTF Transfer Quality

The quality of DTF transfers is predominantly influenced by their size. As transfers become larger, maintaining clarity and detail in the design becomes a significant challenge. Larger transfers may appear distorted if produced at low resolutions. To mitigate this, designers must prioritize the creation of high-resolution artwork that will translate effectively to larger scales. Utilizing vector graphics is crucial as they allow designs to scale without losing definition, ensuring that intricate patterns remain sharp even when enlarged.

When assessing quality in larger DTF transfers, performing test prints is indispensable. These tests reveal how the print behaves at the intended size, allowing designers to make necessary adjustments before the final production. This practice is especially vital for designs with fine details, where a loss of clarity can detract from the overall visual appeal. Therefore, investing time in testing can significantly enhance the quality of the final product, ensuring that customers receive vibrant, attractive apparel.

DTF Transfer Size and Fabric Compatibility

The interaction between fabric and DTF transfers is crucial and heavily influenced by the size of the transfer. Different fabrics respond uniquely to heat and pressure, and larger transfers require specific types of materials to ensure a successful application. For instance, heavy cotton fabrics can handle larger transfers quite well, providing a sturdy base for vibrant prints. In contrast, lightweight or stretchy materials such as polyester or spandex may necessitate smaller transfers to avoid problems like peeling or cracking, which are common with oversized applications.

Custom apparel printing using DTF transfers also requires an acute understanding of material properties. As transfer sizes increase, the risk of application errors rises, particularly if the chosen fabric is not compatible. Larger transfers often require higher quality release films that can withstand the heat necessary for transferring the design onto the garment without compromising the print. Therefore, selecting the right size and fabric combination is essential in achieving the desired aesthetic while maintaining the integrity of the garment.

Optimizing the Printing Process for DTF Transfers

The DTF printing process can be complex, and the size of your transfers plays a pivotal role in shaping this process. Larger transfers may necessitate different settings for ink application and heat activation compared to smaller designs. The printing equipment itself may also need adjustments to accommodate for size without losing quality, particularly in terms of adhesive application. It’s crucial for operators to follow manufacturer guidelines to avoid complications during production, ensuring that both small and large transfers adhere properly.

Moreover, the trend towards oversized DTF transfers requires operators to adapt their techniques. Innovations in printer technology have emerged to handle larger designs more efficiently, but this also means that printers need to calibrate settings to maximize print fidelity. For instance, greater ink quantities and extended heat periods might be required to ensure that the larger designs adhere effectively, without experiencing common pitfalls like uneven transfer or fade.

Economic Effects of DTF Transfer Size

Understanding the economic implications of DTF transfer size is crucial for effective cost management in custom apparel production. Larger transfers inevitably consume more materials, which can drive up production costs significantly. When budgeting for projects, it’s important to consider not only the raw materials but also the potential increase in processing time associated with larger designs. These financial factors can impact the overall pricing strategy and profitability of custom printing businesses.

In response to these economic challenges, businesses can implement strategic pricing models that reflect the increased costs of oversized DTF transfers. By analyzing production costs against the intricacy and quality of designs, companies can better position themselves in the market while ensuring their offerings remain competitive. Furthermore, understanding the balance between transfer size and pricing can help manufacturers cater to consumer preferences effectively, maximizing revenue potential.

Emerging Trends in Oversized DTF Transfers

In recent years, the trend toward oversized DTF transfers has taken the fashion industry by storm. Consumers increasingly seek bold, oversized designs that make a statement. This shift not only impacts the types of designs being produced but also places a greater emphasis on the quality and reliability of the printing process. As brands respond to this consumer demand, they must ensure that their DTF printing techniques can handle the intricacies of larger designs.

The evolution of market tastes has prompted innovations within DTF technology, with manufacturers developing specialized equipment suited for larger print dimensions. These advancements ensure that businesses can produce high-quality oversized DTF transfers without compromising on detail or vibrancy. As this trend continues to grow, staying ahead of technological developments will be essential for companies looking to capitalize on the booming custom apparel market.

Designing for DTF Transfer Size Efficiency

Efficiency in design is paramount when creating DTF transfers, especially as size plays a critical role in the printing process. Designers must strategically plan their artwork with size limitations in mind to ensure high-quality outcomes. Incorporating scalable design techniques such as using vector art not only supports various transfer sizes but also enhances the overall visual impact when printed. This foundational practice in design allows for smoother transitions from concept to final product.

Additionally, understanding the implications of size can aid in crafting designs that utilize the print space effectively, minimizing waste. For instance, avoiding complex backgrounds for larger transfers can help focus attention on the main graphic elements, allowing for a cleaner finish and a more appealing presentation. By prioritizing efficiency in design and production, businesses can achieve more with their DTF transfers, maximizing both quality and profitability.

Frequently Asked Questions

How does transfer size impact the quality of DTF transfers?

The size of a DTF transfer significantly affects the print quality. Larger transfers can lose detail unless produced with high resolution. It’s essential to design with the intended transfer size in mind and conduct tests to ensure clarity and color vibrancy, especially for intricate designs.

What materials work best for oversized DTF transfers?

When it comes to oversized DTF transfers, 100% cotton is ideal as it holds larger transfers effectively. However, stretchy materials like spandex may require adjustments in transfer size to ensure quality and prevent issues like peeling or fading.

Are there different printing processes for smaller and larger DTF transfers?

Yes, the printing process varies based on transfer size. Larger DTF transfers often need adjustments in ink application, heat settings, and timings for adhesive activation. Smaller transfers tend to be more forgiving, allowing for easier production.

What economic factors should I consider when using DTF transfers?

Larger DTF transfers typically cost more due to increased material usage and longer processing times, impacting overall efficiency. Understanding these costs can help in developing competitive pricing strategies that reflect the transfer size and design complexity.

How do consumer preferences affect the size of DTF transfers?

Current trends show that consumers prefer larger, eye-catching designs, leading to increased demand for oversized DTF transfers. This shift compels manufacturers to refine their quality assurance processes to meet consumer expectations for bold statements.

What innovations are emerging in the DTF transfer market related to size?

As the demand for oversized DTF transfers grows, advancements in technology are being developed, including specialized printers and transfer papers designed specifically for larger prints, ensuring high-quality results in the custom apparel printing industry.

| Aspect | Key Points |

|---|---|

| Transfer Size and Design Impact | Larger transfers may lose detail; design must accommodate size for clarity and vibrancy. |

| Material Considerations | Fabric choice affects transfer application; adjust size based on material type to avoid issues. |

| Variations in Printing Process | Size influences ink application and heat settings; follow guidelines to ensure quality. |

| Economic Implications | Larger transfers incur higher costs and longer processing times affecting productivity. |

| Emerging Market Trends | Demand for oversized prints is rising; companies must innovate to meet consumer preferences. |

Summary

DTF transfers have a significant impact on the quality and success of custom printing projects. Understanding the influence of transfer size is essential for both manufacturers and consumers as it affects design clarity, fabrication choices, economic efficiency, and consumer satisfaction. With the growing trend towards customization and larger prints, staying informed about these factors will help businesses thrive in a competitive marketplace. Making informed decisions about DTF transfers enables better quality control and a more appealing final product.