DTF Transfers by Size are essential to the success of any custom apparel printing project, as they directly impact the quality and professionalism of the finished product. As the popularity of DTF printing continues to rise among enthusiasts and small businesses alike, understanding how to choose the right transfer sheet sizes becomes crucial. With the right size, you can ensure that your designs are vibrant and detailed, making a statement on t-shirts, hoodies, and more. This guide will walk you through the vital aspects of selecting DTF transfer sizes, helping to minimize waste and maximize your creative potential. Dive in to learn how to make your custom designs pop!

When it comes to selecting the perfect size for your Direct to Film (DTF) transfers, a detailed approach is necessary for optimal results. Identifying suitable transfer dimensions allows you to align your custom printing needs with the capabilities of various transfer sheet sizes. This exploration into DTF transfer sizes encompasses understanding the intricacies of DTF printing and how these sheets can be tailored to meet the demands of different fabrics and designs. By examining the relationship between design scale and transfer size, you can ensure that every piece of custom apparel you produce stands out with clarity and precision.

Choosing the Right DTF Transfers by Size: Understanding the Basics

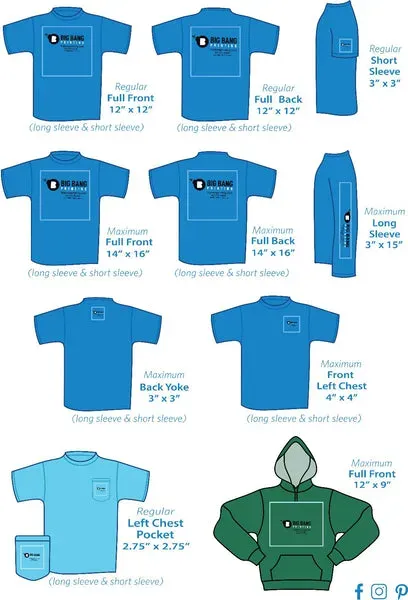

Selecting the appropriate size for DTF transfers is essential for ensuring that your custom designs come out looking crisp and professional. When you’re working with different design dimensions, make it a priority to understand exactly how the size of your transfer sheets impacts the final product. A larger graphic design may require more expansive dimensions on your transfer sheet, allowing for intricate details to shine through without losing quality. On the other hand, if you’re working with smaller designs, you can seamlessly print multiple images on a single sheet, optimizing your materials and reducing costs.

It’s critical to remember that DTF printing sizes aren’t just a one-size-fits-all solution. By accurately measuring your designs and considering their placement on the garment, you can prevent issues like cutting into important design elements, which can severely detract from the overall visual appeal. The various transfer sheet sizes available, such as A4 and A3, provide flexibility, but knowing when to use each size will make your printing process much more efficient.

The Importance of Design Dimensions in DTF Transfers

When embarking on a custom apparel project, the dimensions of your designs should be a fundamental consideration. Each DTF transfer needs to be sized specifically to align with the digital artwork. This means determining not only the height and width but also accounting for the design’s intricacy. For example, detailed designs with small lettering may require a slightly larger transfer size to ensure that all the elements are printed sharply and clearly. In contrast, simpler graphics can be contained within smaller dimensions without compromising quality.

Moreover, understanding how your design dimensions play a role in the functionality of your DTF printing strategy is vital. Designs that appear too small on larger transfer sheets may lose their impact, while oversized designs can overwhelm the garment. Therefore, utilizing software tools that help visualize the intended placement of graphics on various garment sizes can be incredibly beneficial for identifying the ideal transfer dimensions.

Transfer Sheet Sizes: Finding the Perfect Fit

DTF transfer sheets come in an array of sizes, which adds a layer of complexity to your selection process. Commonly offered sizes include A4 and A3, with some providers even offering custom sizes for unique projects. Selecting the right transfer sheet size is crucial — it should not only accommodate your design but also align with how you intend to use that design on your apparel. For example, a larger transfer sheet can be cost-effective for bulk production, as it allows multiple designs to be printed simultaneously, maximizing output efficiency.

Additionally, it’s essential to consider how the size of your transfer sheet plays into your overall production workflow. Printing designs on larger sheets can sometimes simplify the process, especially when dealing with intricate layouts. However, for smaller designs or when dealing with limited resources, smaller sheets may be the better choice, enabling cost savings and less waste in materials. Consequently, assessing your design scope and production goals will help guide you in selecting the most suitable transfer sheet size.

Fabric Compatibility: Why Size Matters

One of the most overlooked factors in choosing the right DTF transfer size is the compatibility with the fabric being used. Different materials react differently to the heat and pressure applied during the transfer process. For instance, stretchy fabrics such as lycra require careful handling when it comes to transfer dimensions, as overextending a design can lead to cracks or peeling over time. Herein lies the importance of selecting sizes that complement the fabric’s characteristics.

Understanding the relationship between your transfer size and fabric type allows for improved adhesion and durability in the final product. Fabrics like cotton may tolerate slightly larger transfers, while more delicate materials often require precision. It’s advisable to conduct test prints on fabric samples to gauge the best transfer size for ensuring a lasting print. Moreover, employing the right size not only enhances aesthetics but can also contribute significantly to the garment’s longevity.

Recent Trends in DTF Transfers: Innovations Impacting Size Selection

The landscape of DTF printing is evolving rapidly, with sustainability and technological advancements leading the charge. With the rising demand for eco-friendly practices, many printers are now offering biodegradable DTF films. These innovations not only cater to conscious consumers but also require a rethink of how transfer sizes can be aligned with sustainable materials. When choosing sizes, it’s worth considering options that minimize environmental impact alongside ensuring print quality.

Moreover, advancements in printing technology, such as enhanced resolution and color accuracy, expand the possibilities of design complexity that can be achieved with DTF transfers. As a result, the size options are becoming more varied, catering to designers looking to push the envelope of creativity. This emphasizes the need for selecting the right size in order to fully capitalize on the capabilities of modern DTF printing, which can yield vibrant, long-lasting prints.

Best Practices for Selecting DTF Transfer Sizes for Success

To ensure optimal results in your DTF projects, adhering to best practices for transfer size selection is paramount. Start by taking the time to conduct sample prints before committing to a full run. Testing enables you to evaluate both the design’s appearance and its adherence to the fabric. This precaution saves potential costs on materials and ensures that the final product meets your expectations.

Additionally, leveraging design software equipped with sizing tools can significantly facilitate the process of selecting DTF transfer sizes. These tools can provide insights and recommendations based on the specific dimensions of your designs and the nature of the fabric used. By strategically planning your layout and utilizing technological resources, you can make well-informed decisions that enhance workflow efficiency and deliver high-quality results in your custom apparel endeavors.

Frequently Asked Questions

What are the best practices for choosing DTF transfers by size for custom apparel?

When selecting DTF transfers by size for your custom apparel, it is essential to consider the design dimensions, fabric compatibility, and production volume. Always conduct test prints, utilize sizing guides in design software, and ensure that your chosen transfer sheet sizes align with your specific needs. These practices help optimize the quality and efficiency of DTF printing.

How do transfer sheet sizes affect DTF printing quality?

Transfer sheet sizes are crucial in DTF printing, as using the appropriate size ensures that your designs fit well without being cut off or losing detail. Larger transfer sheets accommodate intricate graphics and help maintain high-quality prints, while smaller sheets are economical for simpler designs. Always match the transfer sheet size with the design dimensions to enhance overall print quality.

Can I use different DTF transfer sizes for various fabric types?

Yes, DTF transfer sizes can be varied for different fabric types. For instance, stretchy fabrics like lycra may require a specific approach to sizing, ensuring that the transfer adheres well without cracking. Rigid textiles like canvas may allow for different sizing flexibility. Selecting the right DTF transfer size based on the fabric type is vital for achieving good adhesion and aesthetics.

Why is it important to measure design dimensions when choosing DTF transfers by size?

Measuring design dimensions before choosing DTF transfers by size is crucial because it determines how well the design fits on the garment and retains its visual impact. Accurate measurements prevent cutting important design elements off the edges of the transfer sheet and ensure the final product meets quality standards.

What role do recent trends play in selecting DTF transfer sizes?

Recent trends in DTF printing, such as the shift towards sustainable materials and advancements in printer technologies, significantly influence the selection of transfer sizes. Sustainable films may offer varying size options, while improved printing precision allows for more intricate designs and shapes. Staying updated on these trends helps ensure your DTF transfer size choices align with market demands.

How can I avoid errors in alignment when using DTF transfers by size?

To avoid errors in alignment when using DTF transfers by size, always create a buffer in your design dimensions. This practices accounts for slight imperfections and ensures that your designs remain intact during the transfer process. Conducting test prints and reviewing alignment before full production will help minimize potential issues.

| Key Consideration | Details |

|---|---|

| Design Dimensions | Measure the height and width of your design and consider placement on the garment. |

| Transfer Sheet Sizes | Available in sizes from A4 to larger formats; align with design dimensions. |

| Fabric Compatibility | Different fabrics affect transfer size; ensure compatibility for better adherence. |

| Production Volume | Bulk orders benefit from maximizing designs per sheet for cost savings. |

| Error Margins | Allow for potential errors in alignment by creating buffer in design dimensions. |

Summary

DTF Transfers by Size are essential in the realm of custom apparel production, influencing both aesthetic and functional outcomes. The proper selection of transfer sizes directly impacts the final product’s quality through the alignment of design dimensions with transfer sheet options, fabric types, and production volumes. Understanding the nuances of size selection not only maximizes efficiency but also minimizes waste, ensuring that each project achieves the highest standards of professionalism and customer satisfaction. By incorporating recent trends and technological advancements, such as sustainable materials and precise printing capabilities, you can enhance your DTF transfer projects, leading to innovative designs that resonate with your target audience.