DTF transfers by size have revolutionized the world of custom apparel printing, providing a dynamic way to showcase designs on textiles. This innovative method utilizes heat transfer printing technology to deliver stunning graphics that can be adjusted for any garment size, ensuring both striking visuals and a perfect fit. As the demand for personalized fashion continues to rise, understanding the intricacies of DTF transfer sizes becomes crucial for anyone involved in this medium. From t-shirts to hoodies, selecting the right DTF transfer materials is essential to achieve the desired effect, durability, and comfort. Stay with us as we explore how varying sizes impact your DTF printing projects, unlocking new potential in the custom apparel market.

When discussing DTF printing, or direct-to-film printing, it’s important to understand how the size of the transfers plays a pivotal role in the overall outcome. This method, known for its heat transfer capabilities and versatility, caters to a wide array of fabric types and sizes, making it ideal for custom clothing. By adjusting the dimensions of the prints, you can ensure that your designs not only fit beautifully but also exhibit vibrant colors and intricate details. As we delve deeper into the topic, we will uncover the best practices for selecting appropriate sizes, as well as materials that work harmoniously with various apparel designs.

What are DTF Transfers?

Direct-to-Film (DTF) transfers have gained immense popularity in the custom apparel printing market due to their innovative approach to design application. This method involves printing images onto a specialized film that is subsequently heat-pressed onto fabric. The DTF printing process is recognized for delivering high-quality graphics with vibrant colors, all while ensuring long-lasting adhesion. The adaptability of DTF technology allows it to cater to a diverse range of fabrics, making it an ideal choice for both professional and hobbyist printers.

Unlike traditional heat transfer printing methods that often require extensive preparation, DTF printing streamlines the process significantly. Printers can easily produce intricate designs that withstand washing and wear, which is appealing for those looking to create custom apparel. The combination of durability and aesthetic appeal makes DTF an essential technique in the ever-evolving world of textile design.

Frequently Asked Questions

What are the standard sizes for DTF transfers in custom apparel printing?

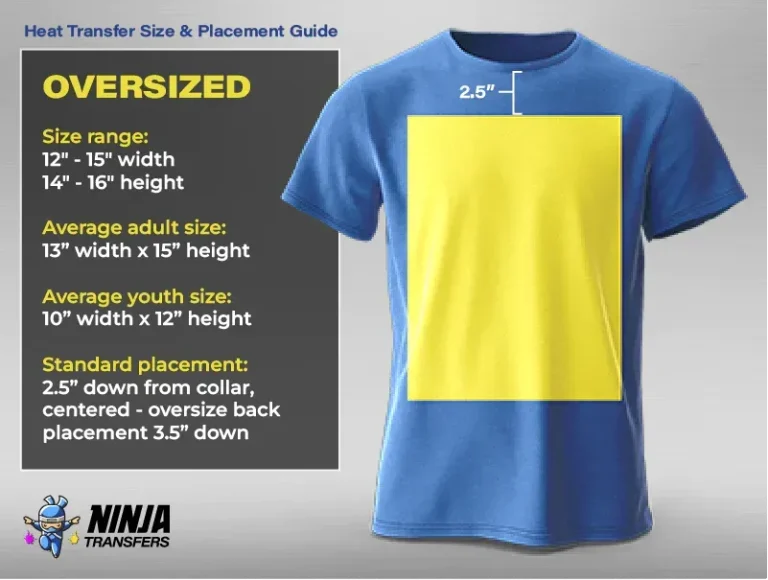

DTF transfers typically come in a range of standard sizes suited for custom apparel printing. Small sizes are about 6×6 inches, ideal for kids’ clothing, while larger options can go up to 15×20 inches for adult apparel. Choosing the right size is crucial to ensure the design’s clarity and impact.

How does the size of DTF transfers affect the final print quality?

The size of DTF transfers significantly influences the final print quality. A design that is appropriately sized will maintain detail and clarity, especially for complex graphics. Incorrect sizing can lead to distorted images or loss of vibrancy in custom apparel prints.

What should I consider when selecting the size of DTF transfers for various garments?

When selecting DTF transfer sizes, consider the application type and the garment style. For instance, a large graphic on a hoodie may require a different size than a smaller design on a t-shirt. Ensuring that the size complements the fit of the garment is essential for a polished look.

Are there any specific materials recommended for larger DTF transfers?

For larger DTF transfers, it is crucial to choose high-quality DTF transfer materials. Films and adhesives should be durable and compatible with various fabrics to ensure the design adheres well and maintains flexibility. Cotton and polyester blends are commonly recommended for larger applications.

How can technological advancements enhance DTF transfers by size?

Recent technological advancements in DTF printing, such as improved print speeds and eco-friendly inks, enhance the quality of transfers by size. These innovations allow for more efficient printing processes while ensuring vibrant and durable designs across different sizes of custom apparel.

What best practices should I follow for sizing DTF transfers?

Best practices for sizing DTF transfers include conducting sample tests on different fabric types and sizes to find the best fit for your designs. Regular printer maintenance is also crucial to ensure quality. Staying informed about size trends and advancements in DTF printing technology will help optimize your results.

| Key Points | Details |

|---|---|

| Introduction to DTF Transfers | DTF printing is a method that uses a special film to apply designs to fabrics through heat and pressure. |

| Importance of Size Selection | Choosing the right size impacts clarity, application types, and market preferences. |

| Material Considerations | Selecting appropriate films and adhesives is crucial for durability and compatibility with different fabrics. |

| Technological Advancements | Innovations are improving print quality, speed, and sustainability through eco-friendly inks. |

| Market Trends | Growing customization demands and low entry barriers are expanding the DTF printing market. |

| Best Practices | Testing, maintenance, and staying updated with industry trends lead to better DTF outcomes. |

Summary

DTF transfers by size are essential for achieving impactful designs on textiles. This method allows for a variety of sizes, adapting to the specific needs of different fabrics and end-uses. By carefully selecting the appropriate sizes, creators can maintain the integrity of complex designs while meeting market demands for custom apparel. Furthermore, understanding the materials and staying abreast of technological advancements can enhance the overall outcome of DTF printing projects. As the industry continues to grow, embracing these aspects will be crucial for success in custom printing.