UV DTF transfers are revolutionizing the world of custom apparel printing, providing a blend of quality, versatility, and innovation that truly stands out. This cutting-edge DTF printing technology utilizes ultraviolet light to create vibrant apparel designs that are not only visually striking but also highly durable. One notable benefit of UV DTF is its ability to adhere to a wide variety of materials, allowing businesses to broaden their product offerings with unique and personalized items. As sustainability becomes increasingly important, the eco-friendly printing options available with UV DTF ensure that brands can meet consumer demand for responsible manufacturing practices. In this guide, we will explore the numerous benefits of UV DTF transfers, setting the stage for brands to harness the power of this transformative printing process.

Discovering the advantages of Direct to Film (DTF) printing opens up a world of possibilities for custom apparel creation. This innovative printing method leverages ultraviolet light technology to achieve stunning color vibrancy and exceptional durability on various materials. With its capability to produce high-quality graphics and intricate designs, DTF printing offers creators a unique tool for expressing their artistic vision. Additionally, the eco-friendly nature of many DTF inks aligns perfectly with today’s consumer values, emphasizing sustainability. As we delve into the key features and benefits of DTF transfers, it becomes clear how this technique is shaping the future of personalized fashion.

The Durability Factor of UV DTF Transfers

UV DTF transfers are recognized for their robust durability, making them a superior choice for custom apparel that undergoes frequent usage and washing. Unlike traditional printing techniques, which can lead to designs cracking or fading, UV DTF transfers maintain their quality over time, ensuring that intricate details and vibrant colors remain intact. This durability not only enhances the longevity of the apparel but also reinforces consumer confidence in the products, making purchases more appealing.

Moreover, the exceptional resistance of UV DTF transfers to wear and tear greatly reduces the need for reprints or replacements. This translates to lower costs over time, as businesses can provide long-lasting apparel without the fear of diminished quality. In an era where consumers are increasingly discerning about the longevity of their clothing, UV DTF’s durability makes it a winning choice in the custom apparel market.

Vibrant Color Reproduction with UV DTF Technology

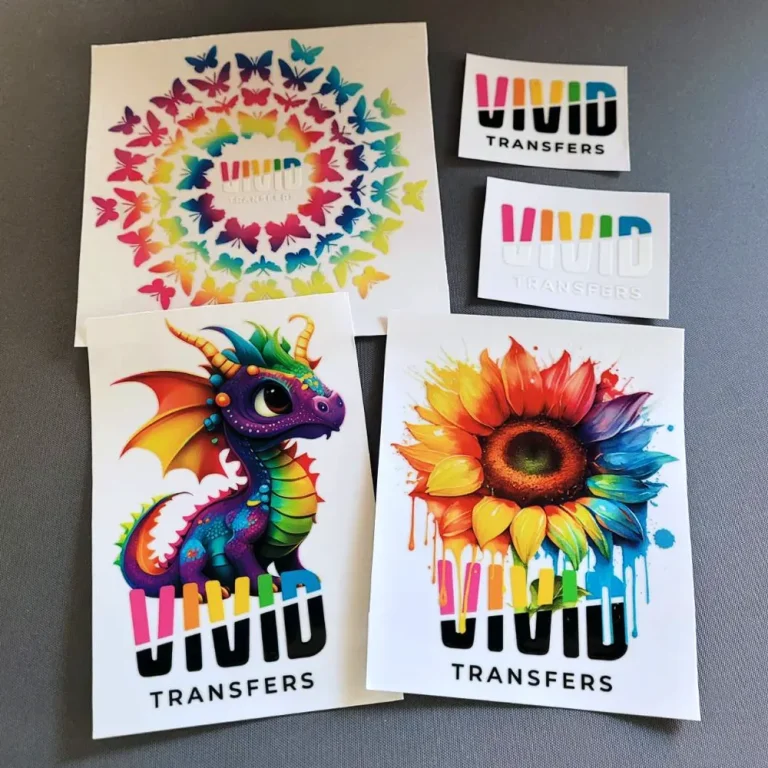

One of the hallmark features of UV DTF transfers is their ability to produce stunningly vibrant colors. The technology allows for high-resolution graphics that can capture even the most subtle design details, making it ideal for custom apparel that requires eye-catching aesthetics. Whether for logos or intricate designs, UV DTF transfers create appealing visuals that draw attention and enhance brand visibility.

The capability of UV DTF technology to reproduce a wide spectrum of colors ensures that designers and brands can fully express their creativity. This level of color vibrancy not only attracts customers but also elevates the overall quality of merchandise. As the demand for custom and personalized apparel increases, having vibrant and appealing graphics is essential for businesses aiming to stand out in a crowded market.

Versatility of UV DTF Transfers in Custom Apparel

The versatility of UV DTF transfers is one of its most significant advantages, enabling applications across a variety of materials including not just fabrics, but also plastics, wood, and leather. This broad compatibility allows businesses in the custom apparel space to expand their product offerings, catering to diverse customer needs. From custom t-shirts to promotional accessories, the creative possibilities with UV DTF are virtually limitless.

This technology empowers garment decorators to experiment with unique combinations of materials and designs, thereby appealing to an expanded audience. By utilizing UV DTF transfers, businesses can create personalized items that resonate with different consumer segments, ultimately driving sales and enhancing customer satisfaction.

Eco-Friendly Aspects of UV DTF Printing

In an age where consumers are more conscious of environmental impact, the eco-friendly nature of UV DTF transfers is particularly appealing. Many UV DTF inks are water-based and contain fewer hazardous chemicals compared to traditional inks, making them a safer choice for both users and the environment. This aspect not only aligns with the growing demand for sustainable practices in the fashion industry but also positions businesses as responsible entities.

By promoting custom apparel printed with eco-friendly UV DTF technology, brands can attract environmentally-minded consumers looking for products that reflect their values. Emphasizing this aspect of the production process can foster a deeper connection with clients, ultimately leading to brand loyalty and repeat purchases as consumers increasingly prioritize sustainability in their buying decisions.

Cost-Effectiveness of UV DTF Transfers

Despite the initial investment needed for UV DTF printing equipment, the long-term cost benefits can be significant. The durability of these transfers reduces the frequency of reprinting and minimizes material waste, allowing businesses to operate more efficiently. By achieving high-quality results with less waste, companies can enhance their profit margins while offering competitive pricing.

Additionally, the efficiency of the UV DTF process streamlines production times, enabling businesses to meet urgent orders without sacrificing quality. By optimizing resources and reducing the likelihood of errors, companies can maximize their output, thereby positioning themselves advantageously in the fast-paced custom apparel market.

Future Innovations in UV DTF Printing Technology

As the demand for personalized apparel continues to rise, the UV DTF printing technology is set to evolve further. Recent advancements have led to faster printer speeds and improved print resolutions, which enhance both productivity and the quality of finished products. These innovations are crucial for businesses aiming to keep up with consumer trends and preferences, ensuring they remain competitive in an increasingly crowded market.

Furthermore, continuous development in UV DTF technology is likely to yield more eco-friendly options and enhancements, aligning with consumer demand for sustainable practices in apparel. As this technology matures, businesses that stay informed and adapt will be best positioned to leverage these advancements for their custom apparel offerings, ensuring relevance in the dynamic landscape of fashion and apparel.

Frequently Asked Questions

What are the main benefits of UV DTF transfers for custom apparel printing?

UV DTF transfers offer several key benefits for custom apparel printing, including high durability that prevents fading and cracking, vibrant colors for stunning graphics, and versatility for use on various materials. Additionally, they provide eco-friendly options, making them a sustainable choice for businesses looking to appeal to environmentally conscious consumers.

How does UV DTF technology improve vibrant apparel designs?

UV DTF technology excels in producing vibrant apparel designs by utilizing advanced printing techniques that enhance color reproduction and detail resolution. This results in high-quality graphics that are visually striking and can be applied to various fabric types, ensuring that custom apparel stands out in any setting.

Is UV DTF printing eco-friendly compared to traditional printing methods?

Yes, UV DTF printing is considered eco-friendly because many of its inks are water-based and contain fewer harmful chemicals compared to conventional inks. This makes UV DTF transfers a sustainable choice for businesses focused on reducing their environmental impact while producing custom apparel.

What types of materials can UV DTF transfers be applied to?

UV DTF transfers are highly versatile and can be applied to a wide range of materials, including various fabrics, plastics, leather, and wood. This flexibility allows businesses in the custom apparel sector to create unique products that cater to diverse customer preferences.

Can UV DTF transfers help reduce production costs for custom apparel?

Absolutely! Although the initial investment in UV DTF technology may be significant, it leads to long-term cost savings by ensuring high durability and reducing material waste. This efficiency allows businesses to minimize errors and maintenance costs, ultimately enabling competitive pricing for custom apparel.

How can businesses stay updated with the latest UV DTF printing advancements?

Businesses can stay informed about the latest UV DTF printing advancements by participating in workshops and training programs offered by various organizations. These initiatives help individuals and companies enhance their skills, keeping them competitive in the evolving market for custom apparel.

| Key Benefit | Description |

|---|---|

| High Durability | UV DTF transfers are exceptionally durable, resisting cracking and fading, making them perfect for garments used frequently. |

| Vibrant Colors | Produces vivid colors and high-resolution graphics, enhancing aesthetics on various fabric types. |

| Versatility | Applicable to multiple surfaces including plastics and leather, expanding creative possibilities for designers. |

| Eco-Friendly Options | Many UV DTF inks are water-based with fewer harmful chemicals, making them a more sustainable printing choice. |

| Cost-Effectiveness | The durability leads to less material waste and reduced maintenance costs, providing competitive pricing opportunities. |

Summary

UV DTF transfers are revolutionizing the custom apparel industry by providing unparalleled advantages over traditional printing methods. This innovative technology not only ensures exceptional durability, vibrant colors, and versatility but also aligns with eco-friendly practices. Businesses ready to embrace UV DTF transfers can enhance their product offerings while advocating for sustainable solutions in the fashion industry. As market demand for personalized apparel continues to grow, UV DTF transfers will play a crucial role in shaping the future of custom garment decoration.