In the world of textile printing, DTF transfers by size have revolutionized the way we approach custom designs. Direct-to-Film (DTF) printing utilizes cutting-edge technology to produce high-quality transfers that are perfect for a variety of fabrics. Understanding the importance of DTF transfer sizes is essential for achieving the desired impact, as different sizes offer unique benefits for various applications. Whether you are creating bold graphics for a promotional event or intricate designs for custom apparel, the right size can enhance both the visibility and overall appeal of your work. This guide will explore how to choose DTF transfer sizes to elevate your projects and capitalize on the capabilities of DTF printing.

When it comes to fabric printing, sizing plays a pivotal role in DTF transfers, also known as Direct-to-Film transfers. This innovative printing approach allows for vibrant designs to be transferred onto different textiles efficiently. By considering factors such as garment type and design aesthetics, businesses can make informed decisions about DTF print sizes, optimizing their products for striking visuals. From small logos on casual wear to expansive graphics for marketing banners, the versatility of DTF transfer applications caters to a wide array of creative needs. These customizable prints not only fulfill individual preferences but also align with industry trends towards personalization and unique branding solutions.

The Benefits of DTF Transfers in Custom Printing

DTF transfers have revolutionized the custom printing landscape, offering an array of benefits that appeal to both professionals and hobbyists. One of the most significant advantages of DTF printing technology is its ability to create high-quality, vibrant designs that adhere effortlessly to various fabric types. Unlike traditional methods, DTF transfers allow for intricate details and a broad color palette, ensuring that every design pops with clarity and style. Additionally, DTF transfers can be easily printed in bulk, making them a practical choice for businesses looking to satisfy high-volume orders without compromising on quality.

Another crucial benefit is the versatility in application. DTF transfers can be used on cotton, polyester, and blends, making them ideal for a variety of products, from t-shirts to sportswear and promotional items. As customization continues to thrive, DTF technology supports demand by allowing small businesses and entrepreneurs to produce unique, personalized items while maintaining cost efficiency. The ease of applying DTF transfers also reduces production time, allowing artists and entrepreneurs to focus on creativity and expansion of their product offerings.

DTF Transfer Sizes: Finding the Perfect Fit

Selecting the right DTF transfer size is essential for ensuring that your designs not only capture attention but also fit the intended application perfectly. For instance, smaller transfer sizes such as 4″ x 4″ are ideal for t-shirt logos or small designs, making them an optimal choice for personal branding or subtle statements. On the other hand, larger sizes like 12″ x 16″ are required for hoodies and banners to maximize visibility and create a striking impact. Understanding the specific requirements of the garment or product type will guide you in making the right decisions for your DTF printing projects.

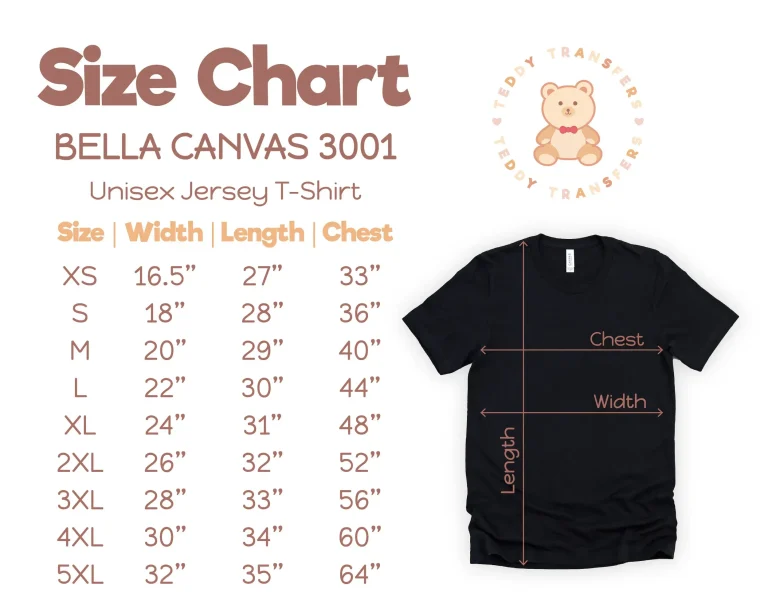

Additionally, visual aesthetics play a significant role when determining the appropriate transfer size. A well-proportioned design ensures that the artwork enhances the overall look of the fabric rather than overwhelming it. Some suppliers provide printable sizing charts that help visualize how different transfer sizes will fit onto various textiles, offering guidance on achieving the best presentation for each piece. This attention to detail is critical, as the perfect transfer size can elevate your design by ensuring that it resonates well with customers and enhances its marketability.

Trends Influencing DTF Printing in Various Industries

The DTF printing market is experiencing a surge in demand for customization as consumers seek unique products tailored to their personal tastes. This trend has opened significant opportunities for businesses that can provide bespoke DTF transfers. Companies can leverage the flexibility of sizes in DTF printing to cater to a wide array of applications, from fashion to promotional products, contributing to a dynamic industry landscape. As customization continues to dominate consumer preferences, the need for versatile transfer sizes becomes increasingly apparent, allowing businesses to meet diverse client needs efficiently.

Moreover, technological advancements in DTF printing have further facilitated the customization process. Today’s DTF printing machines are equipped with enhanced capabilities that allow for higher resolutions and improved color accuracy. This has enabled suppliers to offer more intricate designs and a wider array of size options for DTF transfers, catering to the evolving demands of the market. As businesses strive to stand out in a competitive landscape, the ability to produce high-quality, customized prints in various sizes is paramount to their success.

Exploring DTF Printing Applications Across Sectors

DTF printing technology extends beyond just the fashion industry; its applications range from promotional products to sportswear and event merchandise. This diversity allows businesses to tap into multiple markets, increasing their reach and revenue potential. Entrepreneurs appreciate DTF printing for its low cost of entry, especially when compared to traditional screen printing or dye-sublimation methods. This affordability makes it a favored choice for small businesses looking to offer unique products without substantial financial investment.

Furthermore, DTF transfers’ capability to be applied to a range of textiles fosters a playground of creativity for designers and brands alike. Customized sports jerseys, branded merchandise for corporate events, and personalized gifts are just a few examples of how DTF printing meets consumer demands. As the industry evolves, embracing DTF printing across varied sectors enables brands to remain relevant and responsive to the ever-changing market trends.

Technical Tips for Perfect DTF Transfer Application

For successful DTF transfer applications, quality material selection is crucial. Utilizing high-quality inks and specialized films can significantly enhance the outcome of your prints, ensuring that colors remain vibrant and designs are sharp. The right materials can accommodate various DTF transfer sizes without compromising the final product’s appearance. Investing in top-notch materials not only helps in producing aesthetically pleasing designs but also increases the durability and wearability of the finished product.

Additionally, conducting print tests at different sizes is indispensable for achieving optimal results. Running these tests allows printers to evaluate the adherence of the DTF transfer to fabric under various conditions. By adjusting sizes according to the fabric type and application context, you can ensure that the final look meets your creative standards. Effective print testing enhances overall quality while providing opportunities to refine designs for better customer satisfaction.

Maximizing Market Appeal with the Right DTF Transfer Size

Incorporating the appropriate DTF transfer size into your creative workflow is essential for maximizing market appeal. Establishing a keen understanding of your audience allows you to choose designs that resonate well while considering optimal sizes for various applications. A sizeable, eye-catching logo on a t-shirt can attract attention, whereas a subtler design on a smaller garment can appeal to consumers who prefer understated branding. By aligning your DTF transfer choices with market preferences, you create the potential for increased sales and satisfied customers.

Moreover, leveraging customer feedback can further refine your transfer size selection. Understanding client preferences can provide insights into what sizes work best for specific demographics or product categories, enabling you to tailor your offerings accordingly. By staying attuned to the evolving trends in DTF printing and consumer desires, businesses can effectively position themselves in the market, taking full advantage of the versatility offered by DTF transfers across various sizes.

Frequently Asked Questions

What are the common DTF transfer sizes used for custom DTF prints?

Common DTF transfer sizes vary based on the application. For T-shirts, sizes like 4″ x 4″ or 6″ x 6″ are popular for small logos, while larger designs for sweatshirts can range from 12″ x 16″ and beyond. It’s important to match the size to the garment for optimal visibility.

How do I choose the right DTF transfer sizes for my DTF printing projects?

Choosing the right DTF transfer size involves considering the type of garment and the visual impact desired. For smaller items like caps, smaller transfers (4″ to 6″) work well, while larger banners or back prints on sweatshirts may require bigger sizes to ensure the design stands out.

Why is the size of DTF transfers important in DTF printing technology?

The size of DTF transfers significantly affects design visibility and production efficiency. Larger transfers create a more impactful display, perfect for marketing purposes, whereas smaller sizes can enhance branding elements on apparel without overwhelming the design.

What factors should I consider when determining DTF transfer sizes for different applications?

Factors to consider include the garment type, the intended visual effect, and the overall design complexity. For example, larger DTF transfer sizes suit promotional wear, while smaller transfers are ideal for personalized items. A sizing guide from suppliers can help visualize these aspects.

How can DTF transfer sizes enhance customization in fashion?

DTF transfer sizes offer vast possibilities for customization, allowing businesses to create tailored designs for individual tastes. With increasing demand for unique products, selecting the right transfer size ensures designs resonate well with consumers, enhancing their personalized experience.

What testing should I perform to determine the best DTF transfer sizes for my prints?

It’s essential to conduct test prints at various DTF transfer sizes to evaluate how well designs adhere to fabrics and how they appear in real-life settings. This process allows for adjustments that enhance the quality and effectiveness of the final product.

| Aspect | Details |

|---|---|

| DTF Transfers Overview | High-quality printing method that applies designs onto fabrics using heat and pressure. |

| Importance of Transfer Size | The size of the transfer affects visibility and production efficiency; larger transfers are more impactful, while smaller ones are suited for discreet branding. |

| Guidelines for Size Selection | 1. T-Shirts: 4″ x 4″ to 6″ x 6″ for small designs. 2. Sweatshirts: 12″ x 16″ or larger for bigger designs. 3. Banners: Use larger sizes for maximum visibility. |

| Aesthetic Considerations | Balance between transfer size and fabric size is key; oversized logos may look cluttered whereas small logos can appear insignificant. |

| Current Trends | Increased demand for customization and technological advancements allow better designs and print sizes. |

| Applications of DTF Printing | Used across various industries including fashion, promotional products, and sportswear due to cost-effectiveness. |

| Material and Testing | Using high-quality materials enhances transfer quality; testing different sizes ensures the best results. |

Summary

DTF transfers by size play a pivotal role in achieving impressive designs tailored to specific fabrics and applications. Understanding the nuances of selecting the right size is essential for promoting visual impact and brand visibility. Larger transfers can effectively capture attention, making them ideal for bold statements on products, while smaller transfers offer subtler branding opportunities. By considering fabric type, design aesthetics, and current market trends, businesses can optimize their use of DTF technology. Ultimately, mastering DTF transfers by size enables artists and entrepreneurs alike to fulfill the growing demand for customization and vibrant designs in the textile industry.